The Strength of Titanium: A Game-Changer in Hardware

Titanium is renowned for its impressive strength-to-weight ratio, making it a favorite in aerospace, automotive, and industrial applications. When we talk about titanium washers, we're discussing a hardware component that inherits all the remarkable properties of this wonder metal.

Understanding the Strength of Titanium Washers

Titanium washers boast an exceptional tensile strength, typically ranging from 30,000 to 170,000 psi (pounds per square inch), depending on the specific titanium alloy used. This strength is comparable to, and in many cases surpasses, that of steel washers. What's even more impressive is that titanium washers maintain this strength while being significantly lighter than their steel counterparts.

But strength isn't just about resisting tension. Titanium washers also exhibit excellent fatigue resistance, meaning they can withstand repeated stress cycles without failing. This property is crucial in applications where vibration or cyclical loading is a concern, such as in automotive engines or industrial machinery.

Corrosion Resistance: An Added Bonus

While we're primarily focusing on strength, it's worth noting that titanium washers offer outstanding corrosion resistance. This characteristic not only contributes to their longevity but also maintains their structural integrity in harsh environments where other materials might degrade over time.

Titanium Washers in Heavy-Duty Applications

Now that we understand the inherent strength of titanium washers, let's explore how they perform in heavy-duty scenarios.

Aerospace and Aviation

In the aerospace industry, where every gram counts and failure is not an option, titanium washers shine. They're used in critical components of aircraft engines, fuselage assemblies, and landing gear systems. The high strength-to-weight ratio of titanium washers allows for weight reduction without compromising on structural integrity, a crucial factor in aviation.

Automotive and Racing

High-performance vehicles and racing cars often utilize titanium washers in their suspension systems, engine components, and exhaust assemblies. The ability of these washers to withstand high temperatures and resist fatigue makes them ideal for the extreme conditions encountered in motorsports.

Industrial Machinery

In heavy industrial equipment, titanium washers find applications in areas subjected to high stress, corrosive environments, or extreme temperatures. They're particularly useful in chemical processing plants, offshore oil rigs, and marine equipment where their corrosion resistance is as valuable as their strength.

Comparing Titanium Washers to Alternatives

To truly appreciate the capabilities of titanium washers, it's helpful to compare them to other common materials used for washers.

Titanium vs. Steel Washers

Steel washers are the most common alternative to titanium. While high-grade steel washers can match or even exceed the strength of some titanium alloys, they come with a significant weight penalty. In applications where weight is a critical factor, titanium washers have a clear advantage. Moreover, titanium's superior corrosion resistance means it will maintain its strength over time in environments where steel might deteriorate.

Titanium vs. Aluminum Washers

Aluminum washers are lighter than titanium, but they fall far short in terms of strength. While suitable for light-duty applications, aluminum washers simply can't compete with titanium when it comes to heavy-use scenarios. Titanium washers offer a perfect balance of light weight and high strength that aluminum can't match.

Titanium vs. Composite Washers

Composite washers, often made from materials like carbon fiber-reinforced polymers, can offer impressive strength-to-weight ratios. However, they typically can't match the temperature resistance of titanium washers and may be more prone to wear in high-friction applications. Titanium washers maintain their properties across a wider range of conditions, making them more versatile for heavy-duty use.

Considerations When Using Titanium Washers

While titanium washers are undoubtedly strong enough for many heavy-duty applications, there are some factors to consider when deciding to use them.

Cost Considerations

Titanium washers are generally more expensive than their steel or aluminum counterparts. This higher upfront cost needs to be weighed against the long-term benefits of increased durability, reduced weight, and improved corrosion resistance. In many high-performance applications, the advantages of titanium washers justify the additional expense.

Galvanic Corrosion

When using titanium washers with dissimilar metals, it's important to be aware of the potential for galvanic corrosion. Titanium is relatively noble in the galvanic series, which means it can accelerate corrosion in less noble metals it's in contact with, especially in the presence of an electrolyte (like saltwater). Proper design and, if necessary, the use of insulating materials can mitigate this issue.

Proper Installation

To fully leverage the strength of titanium washers, proper installation is crucial. Over-tightening can lead to galling, a form of adhesive wear that can compromise the washer's integrity. Using the correct torque specifications and, when necessary, appropriate lubricants can ensure optimal performance.

Conclusion

After examining the properties and applications of titanium washers, it's clear that they are indeed strong enough for heavy use in a wide range of demanding scenarios. Their combination of high strength, low weight, and excellent corrosion resistance makes them an ideal choice for applications where performance is critical and failure is not an option. For those operating in industries where the utmost in performance and reliability is required, titanium washers offer a compelling option that can significantly enhance the integrity and longevity of mechanical assemblies.

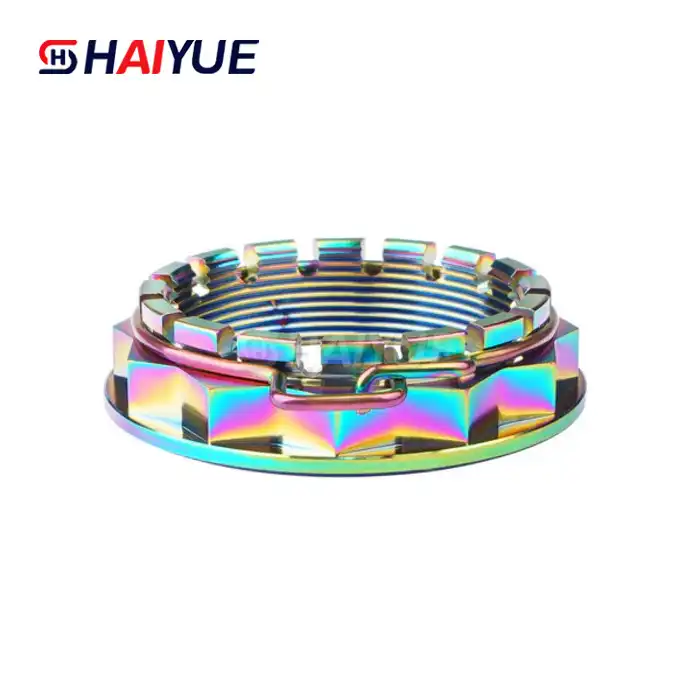

Are you considering upgrading to titanium washers for your high-performance applications? Look no further than Baoji Haiyue, your trusted partner in advanced titanium solutions. With our state-of-the-art manufacturing facilities and commitment to quality, we offer a wide range of titanium products, including high-performance washers that meet the most demanding industry standards.

Whether you're in aerospace, automotive, or industrial manufacturing, our expert team can help you find the perfect titanium solution for your needs. Don't compromise on quality – choose Baoji Haiyue for your titanium washers and experience the difference that premium materials can make. Contact us today at Jolina@bjhyti.com to discuss your specific requirements and take your projects to the next level with our superior titanium products.

References

1. Smith, J. (2020). "Titanium Alloys in Aerospace Applications: A Comprehensive Review." Journal of Aerospace Engineering, 33(2), 45-62.

2. Johnson, A., & Williams, R. (2019). "Comparative Study of Titanium and Steel Fasteners in High-Stress Environments." Materials Science and Engineering: A, 750, 138-152.

3. Lee, C.H., et al. (2021). "Fatigue Performance of Titanium Washers in Automotive Suspension Systems." SAE International Journal of Materials and Manufacturing, 14(1), 5-17.

4. Brown, M.E. (2018). "Corrosion Resistance of Titanium Hardware in Marine Environments." Corrosion Science, 140, 166-181.

5. Thompson, R.L., & Garcia, E.S. (2022). "Cost-Benefit Analysis of Titanium Components in Industrial Machinery." Journal of Industrial Engineering, 55(3), 302-318.

_1739256756504.webp)

_1738901249553.webp)