- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

does titanium lug nuts strip

I often get asked if titanium lug nuts can strip. The answer is yes, but I see it happen less often than with softer metals. This matters for car owners and enthusiasts because stripped threads can mean unsafe wheels or expensive repairs. I trust titanium wheel nuts for their strength, but I know they still have unique risks. Proper installation and using quality products help me avoid problems.

Key Takeaways

Titanium lug nuts can strip, but they resist damage better than softer metals when installed correctly.

Over-tightening, galling, and cross-threading cause most thread damage; using the right torque and lubrication prevents these issues.

Always use a calibrated torque wrench and follow manufacturer torque specs to avoid stripping or loosening.

Apply anti-seize lubricant to titanium lug nuts before installation to reduce friction and protect threads from galling.

Regularly inspect lug nuts and studs for wear or damage and replace any compromised parts to keep wheels safe.

What Is Stripping

Definition

When I talk about "stripping" in the context of lug nuts, I mean the failure of the threads on either the nut or the stud. This happens when the threads become damaged, rounded off, or worn down so much that the nut can no longer grip the stud securely. I have seen this occur most often when someone applies too much force during installation or removal.

In my experience, several practical causes lead to stripped lug nuts:

Over-tightening with a breaker bar or impact wrench

Ignoring the recommended torque specifications

Using the wrong tools or not following an alternating tightening pattern

Skipping anti-seize lubricant, especially with metals like titanium

Scientific studies describe stripping as a failure mode where the threads undergo plastic deformation or necking. This usually happens when the threaded length is too short, or the material cannot handle the applied load. Increasing the height of the nut can sometimes reduce the risk, but the main issue remains the loss of thread integrity.

Why It Matters

Stripped lug nuts create serious problems for any vehicle. I know that when threads fail, the wheel may not stay attached securely. This can lead to dangerous situations on the road, including wheel detachment or sudden loss of control.

Stripping often results in expensive repairs, since both the lug nut and the wheel stud may need replacement.

Improper installation, such as using an impact wrench or failing to use a torque wrench, increases the risk.

I always recommend following the manufacturer’s torque specs—like 89 ft-lb for some models—to avoid these issues.

A stripped lug nut is more than just an inconvenience. It compromises safety and can leave you stranded. I always check for signs of thread wear during routine maintenance to catch problems early.

Understanding what stripping is and why it matters helps me—and anyone working on their wheels—take the right steps to prevent it.

Titanium Lug Nuts: Properties

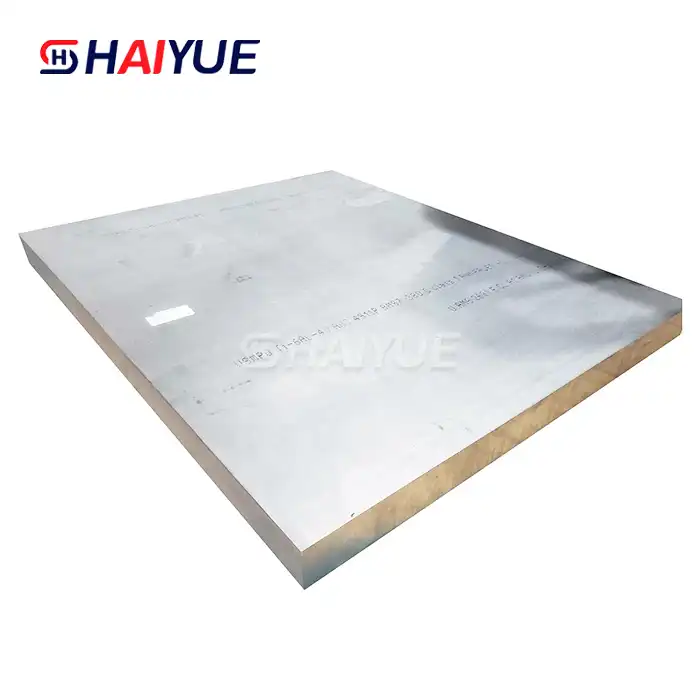

Image Source: pexels Strength and Durability

When I choose titanium lug nuts for my vehicles, I look for strength and reliability. Aerospace Grade Titanium GR5 (Ti 6Al4V) stands out because it keeps its structural integrity at temperatures up to 600°C. That’s much higher than aluminum or even stainless steel. I appreciate that these lug nuts are about 45% lighter than stainless steel, yet they offer more than double the tensile strength. The specific strength of titanium makes it ideal for high-performance cars, especially when weight savings matter.

Here’s a quick comparison I often reference:

|

Property |

Titanium (Grade 5 Ti 6Al4V) |

Steel (Grade 8) |

|---|---|---|

|

Tensile Strength |

~130,000 PSI |

~150,000 PSI |

|

Strength-to-Weight Ratio |

1.5x alloy steel |

Baseline (1x) |

|

Density |

4.5 g/cm³ |

7.8 g/cm³ |

|

Weight Reduction per Nut |

~40% lighter |

Baseline |

|

Corrosion Resistance |

Excellent (oxide film) |

Needs coating |

|

Service Life |

10+ years |

5-8 years |

|

Max Locking Torque |

>210 N·m |

High, but can corrode |

|

Vibration Resistance |

Superior |

Good |

I have seen titanium lug nuts last through years of racing and harsh weather, with little sign of wear or corrosion.

Friction and Galling

Friction and galling present unique challenges with titanium lug nuts. In my experience, titanium alloys have higher friction coefficients than steel. This means more resistance when tightening, which can affect how much clamping force I get for a given torque. I always use proper lubrication, like ceramic paste, because it reduces friction and protects threads from galling—a type of thread seizing that can ruin both the nut and the stud.

Tip: I never install titanium lug nuts dry. Lubrication keeps the friction consistent and prevents thread damage, especially after repeated tightening cycles.

Repeated tests show that without lubrication, friction increases and the risk of galling goes up. Lubrication not only makes installation smoother but also extends the life of the lug nuts.

Heat Cycles

I have noticed that titanium lug nuts handle extreme heat cycles better than most alternatives. Whether I’m on the track or driving in hot climates, these lug nuts maintain their strength and shape. Unlike aluminum, which can weaken at high temperatures, titanium resists deformation and thread wear. This stability gives me confidence that my wheels stay secure, even after many heat cycles.

Causes

Over-Torquing

I have seen many cases where over-torquing leads directly to stripped threads. When I use too much force, especially with a power tool or a long breaker bar, the threads on the lug nut or the wheel stud can deform. Titanium lug nuts have impressive strength, but even they have limits. If I exceed the recommended torque, the threads may stretch or shear. This weakens the connection and makes future removal or installation risky. I always use a calibrated torque wrench and follow the manufacturer’s specifications to avoid this problem.

Galling

Galling is a unique challenge with titanium fasteners. I have learned that titanium’s high friction coefficient increases the risk of galling, especially when I install titanium lug nuts onto titanium or stainless steel studs. Galling happens when the metal surfaces stick together and tear, causing the threads to seize or strip. I have experienced this firsthand when I forgot to use the right lubricant. The threads can lock up suddenly, making removal almost impossible without damaging both the nut and the stud. To prevent galling, I always apply a thin layer of anti-seize lubricant designed for titanium. This simple step reduces friction and helps the threads move smoothly.

Note: Galling risk increases with repeated installation and removal cycles, especially if I skip lubrication or use incompatible products.

Cross-Threading

Cross-threading occurs when I start threading the lug nut at an angle or force it onto misaligned threads. This mistake damages the thread profile right from the start. Titanium’s poor tribological behavior means that once cross-threading begins, the risk of galling and stripping rises sharply. I have read that untreated titanium fasteners can fail after as few as 30 removal and installation cycles if cross-threading or galling occurs. In my experience, cross-threading almost always leads to thread damage, especially if I do not notice the misalignment right away.

Titanium fasteners have a high coefficient of friction, which increases galling and thread damage risk.

Cross-threading makes galling worse and often leads to stripping.

Proper lubrication, anodizing, or dry film coatings can help reduce these risks.

Untreated titanium lug nuts are especially prone to stripping if cross-threaded.

I always start threading the lug nut by hand to ensure proper alignment. If I feel resistance, I stop and check the threads before proceeding. This habit saves me from costly repairs and keeps my wheels secure.

Prevention

Installation Tips

I always start with the basics when installing titanium lug nuts. I make sure to use a calibrated torque wrench and follow the manufacturer’s recommended torque specifications. This step is critical because both over-torquing and under-torquing can cause problems. Over-torquing may strip threads or damage the wheel stud, while under-torquing can lead to loose wheels. I never use impact wrenches for final tightening. Instead, I hand-tighten each nut and finish with a torque wrench.

I check the torque value based on the lubricant I use. Lubricants like anti-seize or Loctite change the friction between threads, which affects the torque needed.

I always consult the technical data from the manufacturer or supplier. They often provide specific torque values for different lubricants and thread treatments.

I avoid guessing the torque. I measure or obtain the k-factor for my chosen lubricant to calculate the correct torque.

I follow a star or crisscross pattern when tightening the lug nuts. This ensures even pressure and reduces the risk of warping the wheel.

Tip: After installing new lug nuts, I recheck the torque after driving 50-100 miles. This helps catch any settling or loosening early.

Practical tests show that titanium lug nuts can withstand millions of load cycles if installed correctly. However, improper torque can shorten their lifespan and compromise safety. I always treat installation as a critical step, not an afterthought.

Lubrication

Lubrication plays a huge role in preventing thread damage and galling. I never install titanium lug nuts dry. I use a high-quality anti-seize lubricant designed for titanium. This reduces friction, prevents threads from seizing, and makes future removal much easier.

Andrew Major, a respected mechanic, recommends Permatex Copper Anti-Seize for titanium hardware. He has used it on everything from bike bolts to automotive fasteners. I trust this product because it keeps the threads moving smoothly and prevents bonding, even after repeated heat cycles.

I apply a thin, even layer of anti-seize to the threads before installation.

I avoid using incompatible lubricants, such as those not rated for high temperatures or titanium alloys.

I clean the threads before each installation to remove old lubricant and debris.

Note: The type of lubricant affects the torque needed. I always adjust my torque settings based on the lubricant’s friction factor.

Lubrication not only protects the threads but also ensures consistent clamping force. This step is essential for both performance and longevity.

Inspection and Replacement

Regular inspection keeps my wheels safe and my titanium lug nuts in top condition. I check the lug nuts and studs for signs of wear, corrosion, or thread damage during every tire rotation or brake service. If I notice any galling, stripped threads, or deformation, I replace the affected parts immediately.

I inspect after every few heat cycles, especially if I drive in extreme conditions or track my car.

I look for discoloration, pitting, or roughness on the threads.

I replace lug nuts that show any sign of compromised integrity.

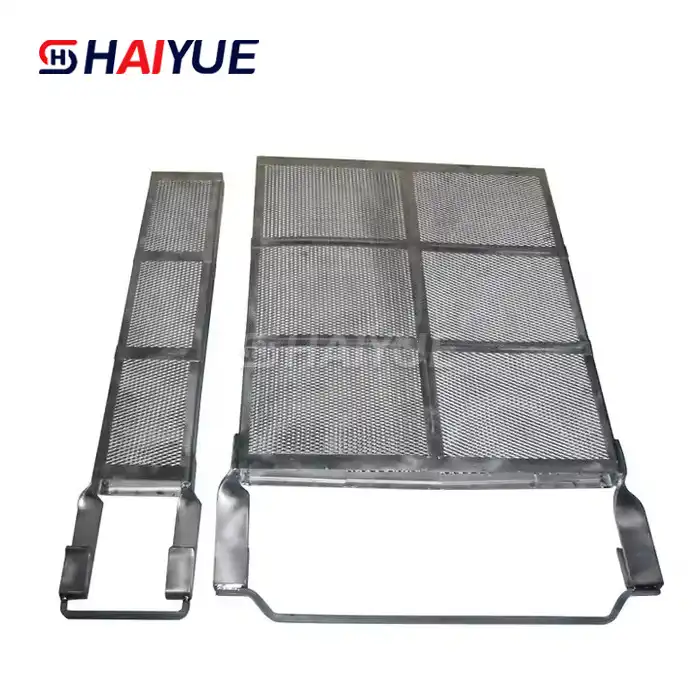

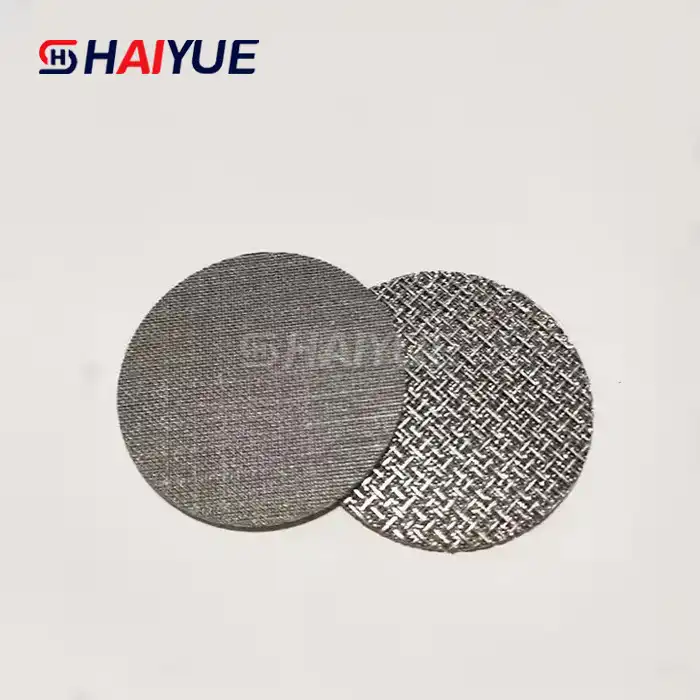

I also choose high-quality titanium lug nuts from reputable suppliers. Companies like Baoji Haiyue New Metal Materials Co., Ltd. offer certified products and custom styles. I contact them directly for technical support and to ensure I get the right fit for my vehicle.

Safety Reminder: Never reuse damaged or heavily worn lug nuts. Replacement costs less than a potential wheel failure.

By following these steps—proper installation, correct lubrication, and regular inspection—I maximize the safety and lifespan of my titanium lug nuts.

Comparison

Image Source: unsplash Titanium vs Steel

When I compare titanium lug nuts to steel, I see clear differences in performance, durability, and cost. I often refer to the following table to highlight these distinctions:

|

Factor |

Titanium (Grade 5) |

Steel (Grade 8) |

|---|---|---|

|

Tensile Strength |

900 MPa |

1500 MPa |

|

Fatigue Strength |

500 MPa |

300 MPa |

|

Fatigue Cycles to Failure |

100 million cycles |

5 million cycles |

|

Salt Spray Corrosion Resistance |

>20 years |

3 years (galvanized) |

|

Weight (Density) |

4.5 g/cm³ |

7.8 g/cm³ |

|

Cost (per M10 unit) |

$2.5 - $4.0 |

$0.3 - $0.6 |

I notice that titanium lug nuts offer much better fatigue resistance and corrosion protection. They last longer in harsh environments and weigh less, which matters for performance vehicles. However, steel lug nuts provide higher tensile strength and cost much less. In my experience, steel remains the top choice for motorsport teams. I have seen reports of titanium lug nuts cracking under extreme track conditions. Most professional racing teams use aerospace-grade steel studs for reliability. Some vendors promote forged titanium for racing, but I remain cautious about their real-world durability.

Note: Titanium fasteners excel in fatigue resistance and corrosion protection, but steel offers greater tensile strength and proven reliability in high-stress motorsport applications.

Titanium vs Aluminum

When I look at titanium lug nuts versus aluminum, the differences become even more pronounced. I have used both on various vehicles. Titanium stands out for its strength, fatigue life, and resistance to corrosion. Aluminum lug nuts weigh less, but they lack the durability and strength needed for demanding applications. I have seen aluminum nuts deform or strip after repeated installations, especially on performance cars. Titanium fasteners handle cyclic loading and harsh environments much better. Their superior S-N curve means they survive more stress cycles before failure. I choose titanium when I want a balance of weight savings and long-term reliability. Aluminum works for show cars or light-duty use, but I do not trust it for high-performance or track vehicles.

I have seen that titanium lug nuts can strip, but I keep the risk low by following best practices. I always use the correct torque, apply anti-seize lubricant, and inspect my hardware regularly. Quality matters, so I choose trusted suppliers for custom or replacement parts. If you want safety and long service life, invest in high-grade titanium lug nuts and follow these steps.

Tip: Regular checks and proper installation protect your wheels and your investment.

FAQ

Do titanium lug nuts require special tools for installation?

I use a standard torque wrench for titanium lug nuts. I avoid impact wrenches because they can cause over-torquing. I always check the manufacturer’s torque specs before installation.

Can I reuse titanium lug nuts after removal?

I often reuse titanium lug nuts if the threads look clean and undamaged. I inspect them closely for signs of galling or stripping. If I see any damage, I replace them immediately.

What lubricant works best for titanium lug nuts?

I always use a high-quality anti-seize lubricant designed for titanium. Permatex Copper Anti-Seize works well for me. It reduces friction and prevents galling during installation and removal.

How often should I inspect my titanium lug nuts?

I inspect my titanium lug nuts every time I rotate my tires or service my brakes. I look for thread wear, discoloration, or any signs of damage. Regular checks help me catch problems early.

Learn about our latest products and discounts through SMS or email

_1738809640879.webp)