- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

6-4 titanium rod

2.High corrosion resistance in harsh environments.

3.Precision machining ensures superior dimensional accuracy.

4.Long-lasting durability for industrial and medical uses.

5.Lightweight yet robust, ideal for aerospace engineering.

6-4 Titanium Rod: Premium Performance for High-Demand Industries

Product Introduction

Welcome to the world of advanced materials with our premium 6-4 titanium rod, a versatile and high-performance solution for industries requiring lightweight, strong, and corrosion-resistant materials. As a leading product from Baoji Haiyue New Metal Materials Co., Ltd., our 6-4 titanium rods are crafted to meet the highest standards, serving sectors like aerospace, medical devices, energy, and chemical processing. Whether you're working on complex aerospace components, medical implants, or high-performance industrial applications, the 6-4 titanium rod is your go-to material for precision and reliability.

Technical Specifications

Below are the key technical specifications of our 6-4 titanium rods, designed to meet international standards. These rods are offered in various sizes and lengths to suit your specific needs.

| Property | Specification | Notes |

|---|---|---|

| Material Type | Ti-6Al-4V (Grade 5) | ASTM B348, AMS 4928, ISO 5832-3 |

| Composition | 90% Titanium, 6% Aluminum, 4% Vanadium | Balances strength and corrosion resistance |

| Density | 4.43 g/cm³ | Lower than many steels for weight savings |

| Tensile Strength | 930 MPa (135 ksi) | High strength, ideal for high-stress parts |

| Yield Strength | 828 MPa (120 ksi) | Reliable under heavy loads |

| Elongation | 10-15% | Excellent ductility for processing |

| Modulus of Elasticity | 113.8 GPa | Provides stiffness for structural applications |

| Hardness (Vickers) | 349-383 HV | Hardness range for enhanced wear resistance |

| Melting Point | 1,670°C | High temperature performance |

Production Grades and Standards

We provide 6-4 titanium rods in the following standards across the globe:

| Country | Grade/Standard | Specification |

|---|---|---|

| USA | Ti-6Al-4V (Grade 5) | ASTM B348, AMS 4928 |

| Russia | Ti-6Al-4V | GOST 19807-91 |

| Japan | Ti-6Al-4V (Grade 5) | JIS H4600 (Titanium) |

|

|

|

|

|

|

|

|

Product Features (Key Features)

Our 6-4 titanium rod stands out for several key features:

- High Strength-to-Weight Ratio: With a tensile strength of 930 MPa and a low density, these rods are ideal for applications where weight reduction is critical.

- Excellent Corrosion Resistance: Naturally resistant to rust and corrosion, especially in harsh environments like marine, chemical, and aerospace industries.

- Biocompatibility: Safe for use in medical devices, offering non-toxicity and compatibility with human tissues.

- Versatile Machinability: Despite its strength, 6-4 titanium is relatively easy to machine, making it a preferred choice for custom designs and precision components.

- High Temperature Resistance: Performs well under high-temperature conditions, making it suitable for high-heat applications like aerospace engines.

Applications

Our 6-4 titanium rods are used in various critical industries, including:

- Aerospace & Aviation: Aircraft frames, turbine blades, fasteners, and landing gear.

- Medical Devices & Healthcare: Surgical tools, prosthetics, orthopedic implants, and dental materials.

- Chemical Processing: Reactor components, storage tanks, heat exchangers, and piping.

- Energy Sector: Nuclear reactors, solar panels, and wind turbine components.

- Marine Engineering: Offshore structures, shipbuilding components, and underwater fasteners.

- Industrial Manufacturing: Tools, fasteners, machinery parts, and high-strength equipment.

Manufacturing Process

Our 6-4 titanium rods are manufactured through a meticulous process that ensures the highest quality and consistency:

- Raw Material Selection: We start with high-grade titanium ingots to ensure superior quality.

- Hot Working: The titanium is heated and forged into the required shape, optimizing mechanical properties.

- Cold Working & Rolling: The material undergoes cold working processes for dimensional accuracy and surface finish.

- Heat Treatment: The rods are heat-treated to improve strength, hardness, and ductility.

- Surface Finishing: Final polishing and surface treatment enhance resistance to corrosion and wear.

- Quality Control: Each rod is inspected for dimensional accuracy, surface defects, and mechanical properties.

Quality Assurance

Baoji Haiyue New Metal Materials Co., Ltd. maintains a stringent quality control process throughout the manufacturing cycle. Our 6-4 titanium rods undergo:

- Ultrasonic Testing: To detect internal flaws or inconsistencies.

- Spectral Analysis: To verify the composition and ensure compliance with international standards.

- Dimensional Inspection: Every rod is measured for precise dimensions and tolerances.

We are certified with ISO9001:2015, AS9100D, and other industry standards, ensuring top-tier reliability.

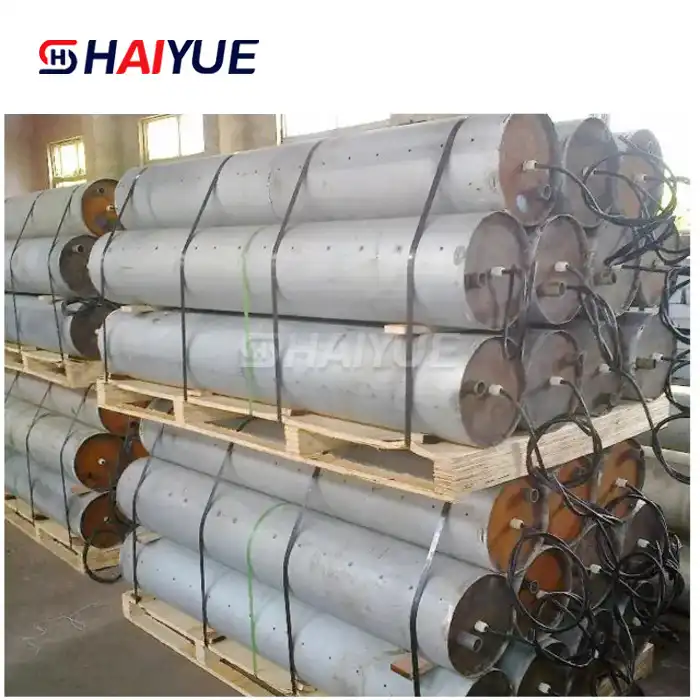

Packaging and Logistics

Our 6-4 titanium rods are carefully packaged to avoid any damage during transit. Each rod is wrapped in protective material, and packed in sturdy crates or boxes. We offer flexible shipping options, including air freight, sea freight, and express delivery, ensuring that your order reaches you on time, no matter where you are in the world.

Customer Support

We are committed to providing outstanding customer support throughout your purchasing journey:

- Pre-Sales Support: Our technical team is available to guide you through product selection, material specifications, and application recommendations.

- Post-Sales Assistance: We offer support for installation, product usage, and troubleshooting.

- After-Sales Service: Our customer care team ensures that all concerns are addressed promptly, including returns and replacements.

Why Choose Us

At Baoji Haiyue New Metal Materials Co., Ltd., we offer:

- Complete Product Range: Extensive variety of titanium and other advanced metal products.

- Full-Process Production: From raw material to finished product, ensuring quality control at every stage.

- Customized Products: Tailored solutions to meet your exact specifications.

- Global Reach: Serving industries worldwide with fast delivery and reliable service.

- Fast Delivery: We prioritize speed without compromising quality.

- Timely After-Sales Service: Worldwide support for all your needs.

OEM Services

We offer OEM services to provide tailored 6-4 titanium rods for your specific applications. Whether you need custom dimensions, unique specifications, or specialized treatments, our team is ready to collaborate with you.

Frequently Asked Questions (FAQs)

Q: What industries use 6-4 titanium rods? A: Aerospace, medical, chemical, energy, marine, and industrial manufacturing industries are the primary users of 6-4 titanium rods.

Q: Are the 6-4 titanium rods biocompatible? A: Yes, 6-4 titanium rods are widely used in medical implants due to their biocompatibility and non-toxicity.

Q: How do I order 6-4 titanium rods? A: You can contact us directly via email or phone for a quote and order details.

Contact Details

For more information or to request a quote, reach out to us at:

- Email:Jolina@bjhyti.com

- Phone: +86-18392721678

Development History

Company founded in Baoji, "Titanium Valley," specializing in titanium and non-ferrous metals.

Expanded product range to include zirconium, tantalum, nickel, tungsten, and molybdenum products.

Achieved ISO9001:2015 certification, ensuring high-quality production standards.

Upgraded manufacturing facilities, adding VAR furnaces, CNC machinery, and advanced heat treatment systems.

Expanded global presence, establishing partnerships in the United States, Germany, and South Korea.

Obtained AS9100D certification for aerospace industry compliance and advanced product quality.

Introduced customized solutions for the aerospace, medical, and energy industries, enhancing global reach.

Celebrated 14 years of excellence with over 2,000 tons of annual titanium production capacity.

Product Quality Management

Production and Processing

Workshop and Equipment

Packaging

Main Products

Applied Industries

Be used in a wide range of industries.

Electrolytic copper foil manufacturing industry

Hydrometallurgy industry

Sewage treatment industry

Cyclone electrolysis industry

Etching liquid electrolysis recovery industry

Electrolytic sodium hypochlorite industry

Learn about our latest products and discounts through SMS or email

(1)_1738919110992.webp)

_1743990673180.webp)

_1736844160512.webp)