- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why Are Modified Titanium Wheel Lug Nuts Becoming the Preferred Choice for Performance Cars

Introduction

Modified Titanium Wheel Lug Nuts have gained widespread attention in the high performance automotive sector Once used mainly in aerospace and motorsport titanium is now making its way into street legal vehicles and aftermarket upgrades With rising demand for lightweight yet durable fasteners titanium lug nuts are quickly becoming the preferred option for enthusiasts builders and technical buyers

This article dives deep into the mechanical reasoning material science and installation considerations behind the adoption of modified titanium lug nuts It also addresses their behavior over long term use and provides insights for those considering replacing standard steel components with advanced titanium alternatives

What Are the Key Engineering Advantages of Modified Titanium Lug Nuts

The benefits of titanium lug nuts are rooted in the unique physical and chemical properties of titanium Grade 5 titanium also known as 6Al 4V offers a rare combination of high strength low weight and superior resistance to temperature and corrosion

Superior Strength to Weight Ratio

Modified titanium lug nuts weigh significantly less than their steel equivalents While steel offers strong clamping force it adds substantial unsprung weight Titanium offers similar tensile strength with nearly half the mass allowing improved rotational efficiency and reduced inertia at each wheel

For motorsport and track builds every gram of unsprung weight counts A reduction in rotational mass improves throttle response braking consistency and cornering control Modified titanium lug nuts can contribute meaningfully to this by eliminating excess mass where it matters most

Enhanced Thermal Resistance

One of the main failure modes for standard lug nuts in performance applications is heat related deformation Titanium has a much higher threshold for thermal stability compared to steel or aluminum It maintains structural integrity even when exposed to continuous high temperature cycles from braking friction or environmental heat

Modified lug nuts often feature surface design changes such as venting grooves reduced profiles or open end architecture These allow heat to dissipate more quickly and evenly around the hub area reducing the risk of uneven expansion or thermal stress

Corrosion Protection Without Coating

Unlike zinc plated steel or anodized aluminum titanium forms a natural oxide layer that protects it from moisture salt and oxidation This property is especially valuable in humid coastal regions or during winter months when roads are treated with corrosive agents Modified titanium lug nuts require no additional surface coating to remain resistant to rust and pitting

How Do Modified Titanium Lug Nuts Perform Under Long-Term Usage

Understanding the long term behavior of modified titanium lug nuts is critical for anyone investing in high grade components for demanding applications

Resistance to Fatigue and Vibration Loosening

When properly installed and torqued titanium exhibits excellent fatigue resistance Modified lug nuts do not deform or crack under repeated tension cycles even when used on vehicles with stiff suspension setups or high speed load transitions Their resistance to vibration loosening makes them ideal for endurance applications where mechanical reliability is essential

Minimal Thread Wear When Lubricated Properly

Titanium can suffer from galling when installed dry which leads to thread damage or seizing Over time this could compromise the reusability of both the nut and the wheel stud However when anti galling lubricant is applied before installation and torque is applied correctly thread wear is minimal and lifespan increases significantly

Appearance and Finish Longevity

Modified titanium lug nuts often feature colored or burned finishes for visual appeal Over time exposure to heat may slightly dull anodized surfaces but the underlying structure remains unchanged Unlike painted or plated steel titanium does not flake peel or rust Its appearance ages gracefully even under harsh driving conditions

Performance Consistency Over Thousands of Kilometers

Testing across various driving conditions from high altitude mountain passes to track days shows that modified titanium lug nuts maintain torque integrity and mechanical performance even after thousands of kilometers of high stress use Their ability to maintain consistent clamping force without re torque is one of the key reasons they are favored in motorsport and endurance setups

What Should You Know Before Replacing Standard Lug Nuts with Modified Titanium Versions

Making the switch to modified titanium lug nuts involves more than just choosing the correct thread pattern It requires an understanding of installation methods material compatibility and torque procedures

Correct Fitment Is Critical

Titanium lug nuts come in various thread pitches and seat designs such as conical or ball seat Ensure that the lug nut type matches the wheel and hub specification Using mismatched seating surfaces can lead to wheel loosening or uneven clamp load

Use a Lubricant Specifically Designed for Titanium

Do not rely on general purpose lubricants Always use a metal based anti seize compound made for high temperature applications This prevents galling reduces friction and allows for accurate torque readings Improper lubrication is the number one cause of premature thread failure in titanium applications

Apply Torque Using Professional Tools

Avoid using electric or pneumatic impact tools Instead use a calibrated manual torque wrench to apply steady pressure Most manufacturers recommend torque settings between eighty and one hundred foot pounds depending on stud size and vehicle type Torque evenly in a crisscross pattern to ensure balanced pressure on the wheel hub

Inspect Threads and Seating Surfaces Regularly

Even high quality components must be inspected to ensure safety Remove and inspect lug nuts during tire changes or every five to ten thousand kilometers Check for discoloration metal dust or surface scarring If any damage is found replace the nut immediately to prevent failure under load

Avoid Reusing Damaged or Cross Threaded Components

Once a lug nut or wheel stud has been cross threaded or shows signs of stripping it should be removed from service Reusing damaged threads can result in inconsistent torque clamping failure or total detachment during operation

Conclusion

Modified Titanium Wheel Lug Nuts are a highly effective upgrade for anyone seeking to improve performance reliability and visual detail in their wheel assembly They offer measurable benefits in strength weight reduction thermal resilience and corrosion resistance when compared to standard steel or aluminum fasteners

When installed using correct procedures and maintained appropriately modified titanium lug nuts can last through years of demanding use across a variety of driving environments They are not just for looks but offer real engineering advantages that serious buyers and performance enthusiasts should not overlook

Understanding the material properties installation requirements and long term performance behavior of titanium ensures that these components deliver maximum value and safety

Modification and customization physical display:

Grooved closed-end automobile wheel nuts:M12x1.5 M12x1.25 M14x1.5 M14x1.25--45mm

|

|

Side hole hollow car wheel nuts:M12x1.5 M14x1.5 M14x1.25--45mm

|

|

|

|

|

Non-slip knurled hollow car wheel nut:M12x1.5 M14x1.5 M14x1.25--45mm

|

|

|

|

|

Hexagon socket wrench for automobile wheel nuts:M12x1.5 M14x1.5 M14x1.25--35/45/50/60mm

|

|

|

|

Eccentric gasket automobile wheel nuts:M12x1.5 M12x1.25 M14x1.5 M14x1.25--35mm

|

|

Ball pad closed hexagon anti-theft car wheel nuts:M12x1.5--35mm

|

|

Spherical gasket closed knurled anti-theft automobile wheel nuts:M12x1.5-48mm

Spherical anti-theft closed-end automobile wheel nuts:M12x1.5-35mm

|

|

Spherical knurled non-moving gasket automobile wheel nut:M12x1.5-35mm

Spherical open automobile wheel nuts:M12x1.5-45mm

|

|

Spherical open semi-hollow automobile wheel nuts:M12x1.5--35mm

|

|

|

|

Spherical open hollow automobile wheel nuts:M12x1.5--35mm

|

|

|

|

Spherical Washer Automobile Wheel Nuts:M12x1.5--45mm

|

|

|

|

Spherical modified car wheel nuts:M14X1.5--45mm

|

|

External plum anti-theft car wheel nuts:M14x1.5 M14x1.25 M12x1.5--35mm

|

|

|

Duckbill ball anti-theft car wheel nut:M14x1.5 M12x1.5 M12x1.25--35mm

|

|

|

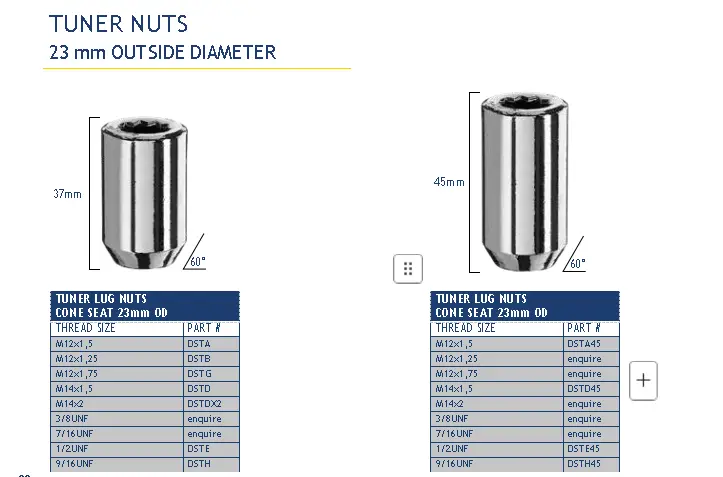

Conical hexagonal open automobile wheel nut:M12x1.25--27 37 45mm

|

|

|

|

|

|

Customized according to the following drawings:

Contact Details

For more information or to request a quote, feel free to contact us:

- Email:Jolina@bjhyti.com

- Phone: +86-18392721678

- Whatsapp:8613772660385

References

Material Selection in Mechanical Engineering Design by M F Ashby

Titanium Alloys Handbook from ASM International

SAE Technical Paper Series on Fastener Performance in High Temperature Applications

Automotive Engineering Case Studies on Lightweight Component Integration

Practical Torque Control Guidelines by Industrial Fasteners Institute

Field Reports on Titanium Lug Nut Performance in Endurance Motorsports

Corrosion Testing of Uncoated Versus Coated Fasteners in Salt Spray Environments

Learn about our latest products and discounts through SMS or email

_1741054683171.webp)

_1736221887266.webp)