- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

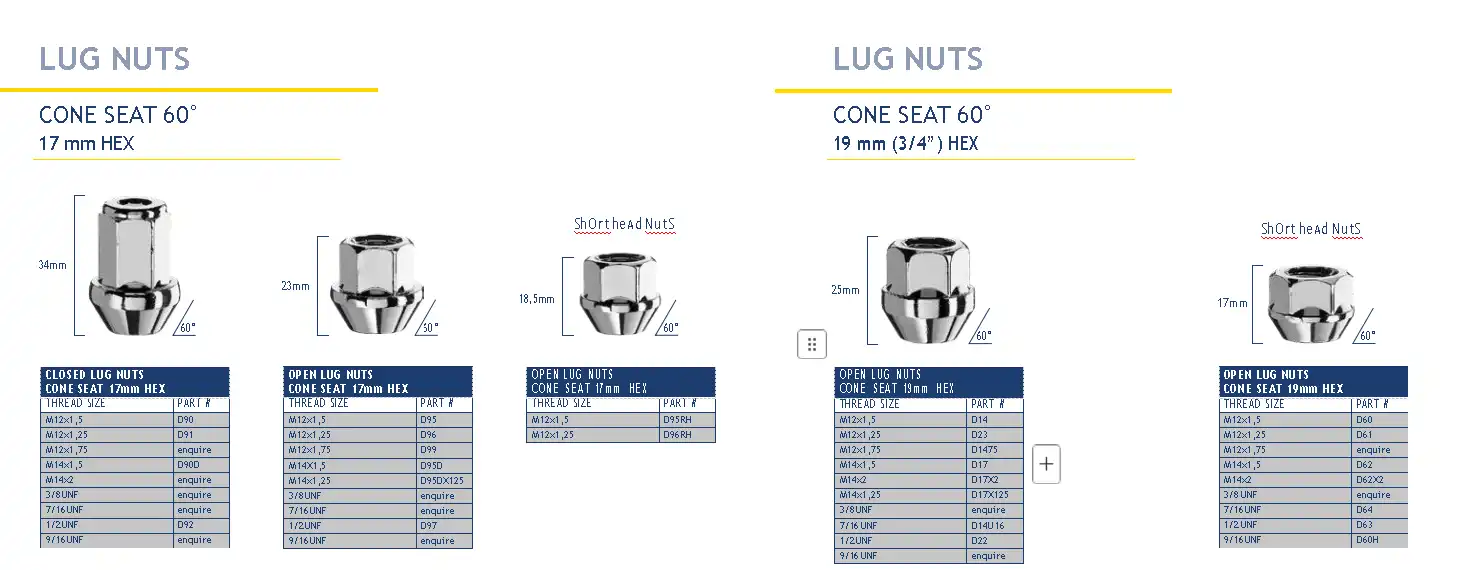

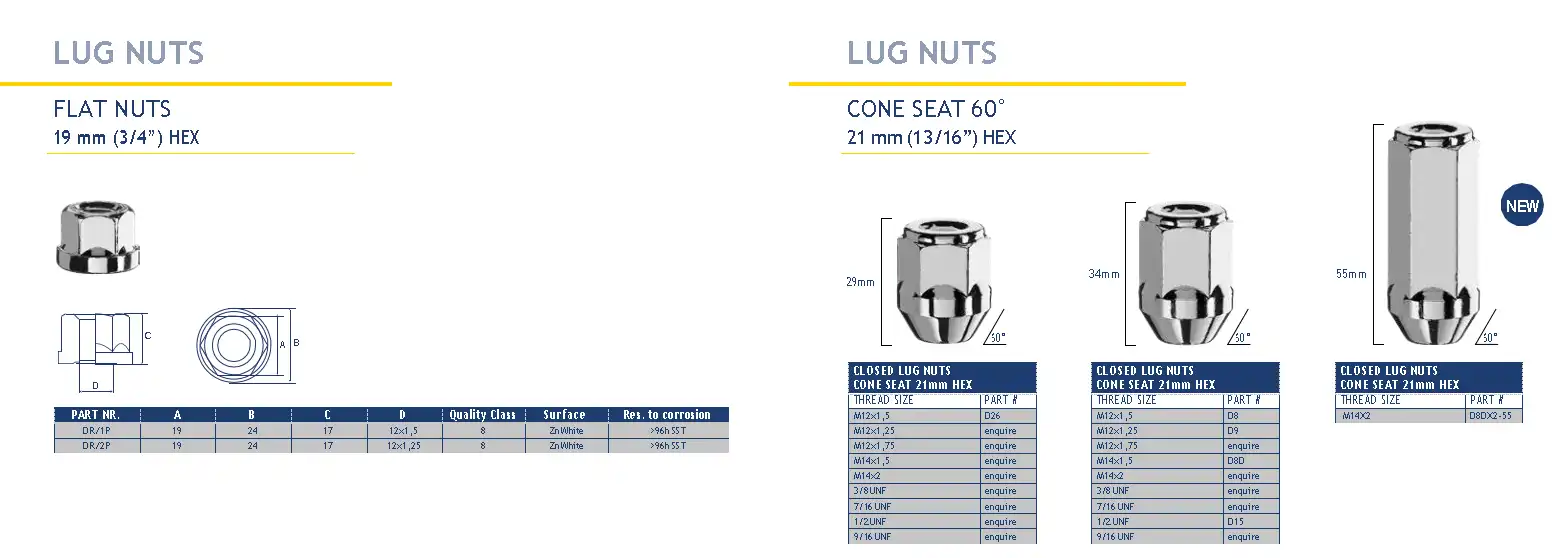

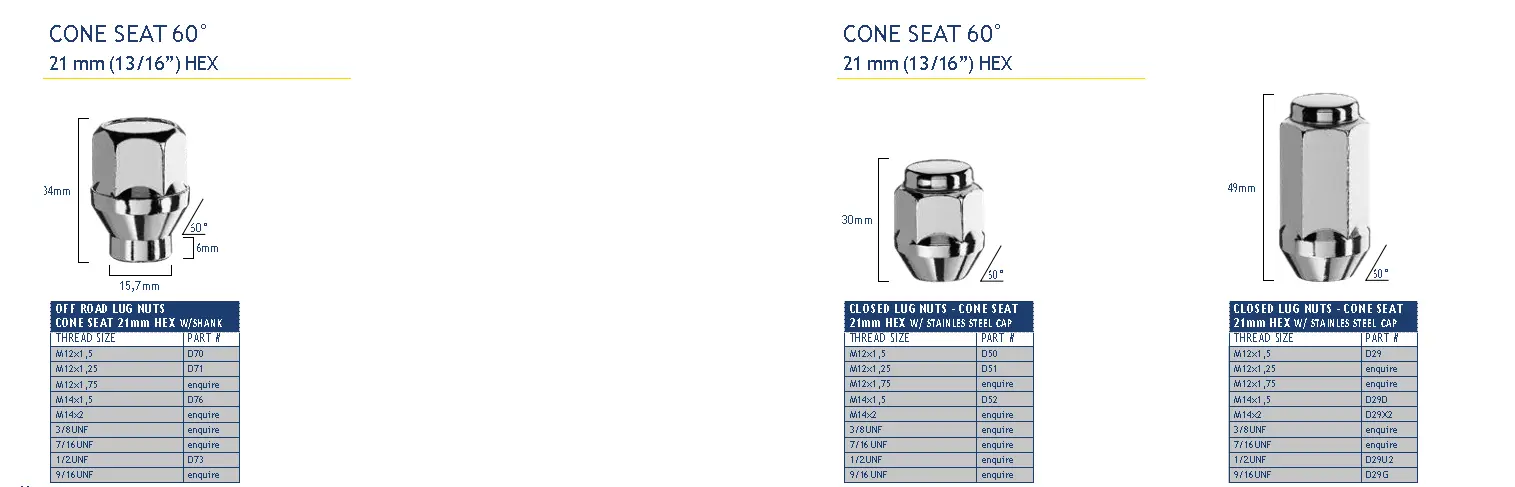

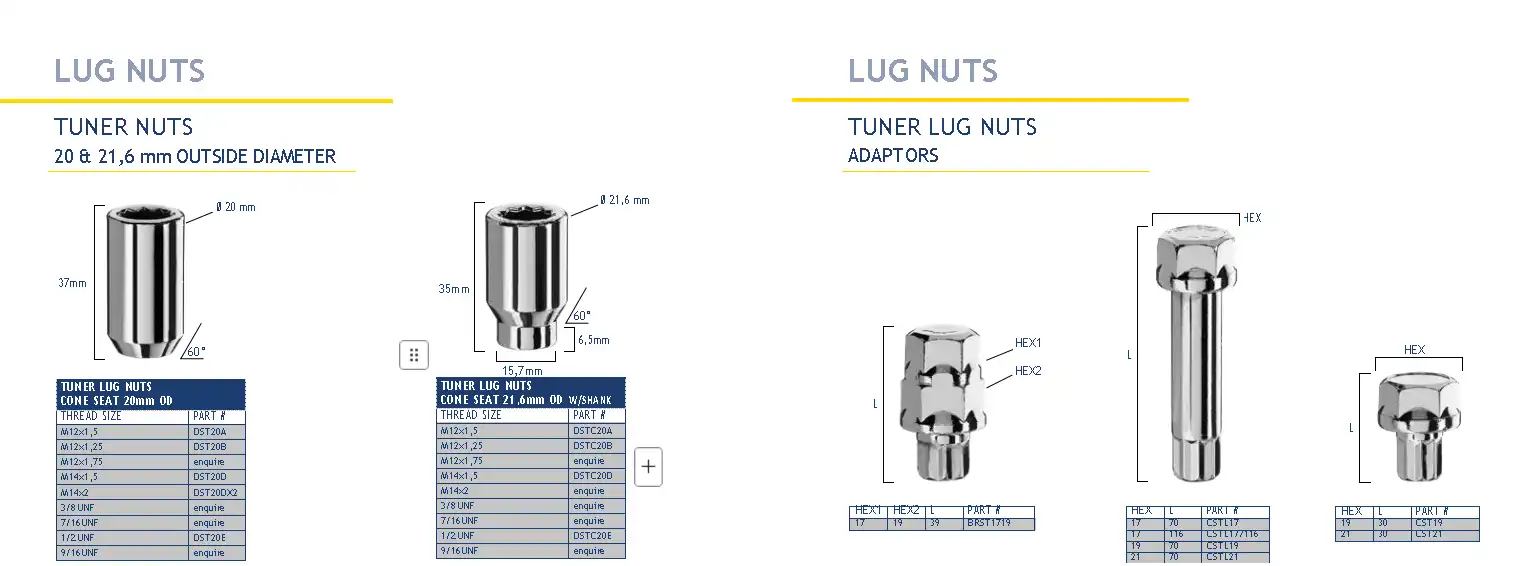

What Makes Modified Titanium Wheel Lug Nuts a Smart Investment for High Performance Builds

Introduction

In automotive engineering the importance of fastener performance is often underestimated Yet in high stress environments like racing mountain driving or extreme climates the choice of wheel lug nuts can significantly impact safety and performance Modified Titanium Wheel Lug Nuts have emerged as a preferred solution for drivers who demand precision reliability and longevity

Why Are Modified Titanium Lug Nuts Used in Motorsports Applications

Motorsports applications expose vehicles to extreme mechanical and thermal loads Braking zones create rapid temperature increases while lateral G forces challenge wheel retention Modified titanium lug nuts are designed to address these conditions using advanced materials and geometry

Lightweight Design Improves Handling

Reducing unsprung mass is a core principle in racing A lighter wheel assembly responds faster to road input and allows for better suspension tuning Modified titanium lug nuts reduce rotational mass which leads to measurable gains in acceleration and braking performance

High Yield Strength Resists Distortion

Grade Five titanium used in most modified lug nuts offers exceptional tensile strength often exceeding nine hundred megapascals This allows the lug nuts to retain their shape under repeated tightening cycles without deforming or cracking

Precision Machining Ensures Perfect Fit

Modified designs typically use CNC machining processes to achieve high thread accuracy and consistent seating surfaces This improves contact uniformity between nut and wheel hub and reduces the chance of loosening during aggressive driving

No Thermal Weakening Under Load

Unlike aluminum which softens at high temperatures titanium maintains its structure even when exposed to heat above four hundred degrees Celsius This ensures consistent clamp force during prolonged track use or heavy braking scenarios

How Do Modified Titanium Wheel Lug Nuts Behave in Harsh Driving Conditions

Real world driving environments like off road trails coastal roads or mountainous terrain test a lug nuts resistance to corrosion impact and thermal variation Modified titanium lug nuts are engineered to handle these stresses without degradation

Resistance to Environmental Corrosion

Titanium naturally forms a passive oxide layer that protects it from moisture oxygen and salt Unlike steel it does not rely on surface coatings or plating which can wear off over time This makes titanium ideal for regions with frequent rain snow or road salt exposure

Low Maintenance Over Time

Once installed correctly with suitable lubrication titanium lug nuts require minimal upkeep They do not rust or seize under normal usage and can withstand repeated torque cycles without weakening This leads to a longer service life compared to standard steel fasteners

Stable Performance Across Temperatures

From cold starts in subzero climates to rapid heating during spirited mountain driving modified titanium lug nuts maintain consistent mechanical behavior They do not expand unevenly nor do they lose grip strength across wide temperature ranges

Minimal Fatigue After Repeated Use

In long distance endurance applications titanium fasteners show superior fatigue resistance Modified versions specifically designed for motorsport often survive hundreds of heat cycles without material loss or structural change

What Key Factors Should Be Considered Before Purchasing Titanium Lug Nuts

While titanium lug nuts offer many advantages improper selection or installation can reduce their effectiveness Buyers should evaluate several technical parameters before choosing modified titanium versions

Correct Thread Pitch and Seat Type

Lug nuts are not universal Ensure the thread size matches the stud specification of the vehicle and that the seat type whether conical or ball matches the wheel hub Incorrect pairing can result in torque loss or unsafe wheel mounting

Choose Reputable Manufacturers

Modified titanium components should come from verified sources that provide material certification and dimensional inspection data Low grade imports often lack proper heat treatment or thread accuracy which increases the risk of galling or failure

Use Recommended Torque Procedures

Torque values must be applied using manual calibrated torque wrenches to ensure accuracy Avoid impact tools which can over tighten and damage the threads Use the cross pattern technique to distribute load evenly during installation

Apply High Temperature Anti Galling Lubricant

Even though titanium is resistant to corrosion it is susceptible to galling when dry Installers should always apply a nickel or copper based lubricant designed for high temperature threaded applications This reduces friction and allows smoother torque application

Inspect Threads Before Reuse

When rotating tires or performing maintenance always inspect both the stud and lug nut threads for signs of deformation discoloration or wear Replacing worn components is crucial for long term reliability and safety

Conclusion

Modified Titanium Wheel Lug Nuts are more than just cosmetic upgrades They represent a step forward in fastener engineering combining the benefits of low mass high strength and corrosion resistance into one component

For high performance vehicles track cars and long range touring setups these lug nuts offer tangible improvements in stability safety and service life When selected properly and installed with attention to detail they outperform conventional steel or aluminum options in nearly every respect

Investing in modified titanium lug nuts is a strategic decision for those who value both performance and durability With the right fitment and care they provide long term returns in safety consistency and mechanical integrity

Modification and customization physical display:

Grooved closed-end automobile wheel nuts:M12x1.5 M12x1.25 M14x1.5 M14x1.25--45mm

|

|

Side hole hollow car wheel nuts:M12x1.5 M14x1.5 M14x1.25--45mm

|

|

|

|

|

Non-slip knurled hollow car wheel nut:M12x1.5 M14x1.5 M14x1.25--45mm

|

|

|

|

|

Hexagon socket wrench for automobile wheel nuts:M12x1.5 M14x1.5 M14x1.25--35/45/50/60mm

|

|

|

|

Eccentric gasket automobile wheel nuts:M12x1.5 M12x1.25 M14x1.5 M14x1.25--35mm

|

|

Ball pad closed hexagon anti-theft car wheel nuts:M12x1.5--35mm

|

|

Spherical gasket closed knurled anti-theft automobile wheel nuts:M12x1.5-48mm

Spherical anti-theft closed-end automobile wheel nuts:M12x1.5-35mm

|

|

Spherical knurled non-moving gasket automobile wheel nut:M12x1.5-35mm

Spherical open automobile wheel nuts:M12x1.5-45mm

|

|

Spherical open semi-hollow automobile wheel nuts:M12x1.5--35mm

|

|

|

|

Spherical open hollow automobile wheel nuts:M12x1.5--35mm

|

|

|

|

Spherical Washer Automobile Wheel Nuts:M12x1.5--45mm

|

|

|

|

Spherical modified car wheel nuts:M14X1.5--45mm

|

|

External plum anti-theft car wheel nuts:M14x1.5 M14x1.25 M12x1.5--35mm

|

|

|

Duckbill ball anti-theft car wheel nut:M14x1.5 M12x1.5 M12x1.25--35mm

|

|

|

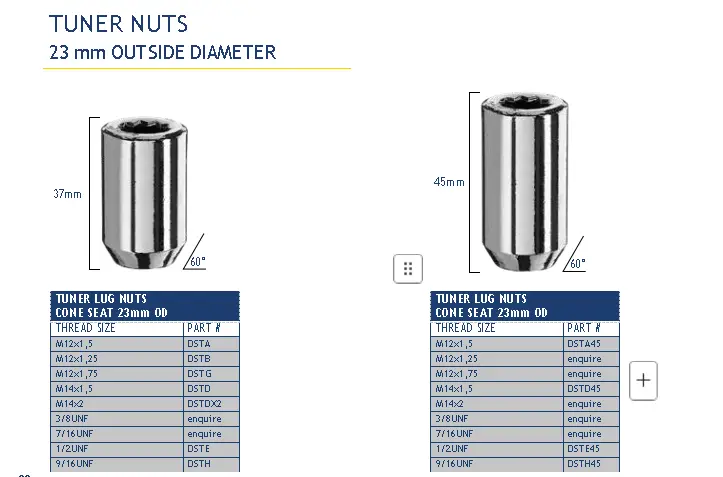

Conical hexagonal open automobile wheel nut:M12x1.25--27 37 45mm

|

|

|

|

|

|

Customized according to the following drawings:

Contact Details

For more information or to request a quote, feel free to contact us:

- Email:Jolina@bjhyti.com

- Phone: +86-18392721678

- Whatsapp:8613772660385

References

Engineering Properties of Titanium Alloys from ASM International

SAE Journal on High Strength Fasteners in Road and Race Applications

Mechanical Behavior of Threaded Joints under Thermal Load

Corrosion Resistance Testing of Aerospace Grade Titanium Components

Vehicle Dynamics and Unsprung Weight Reduction Studies

Case Analysis of Fastener Fatigue in Multi Heat Cycle Environments

Practical Guide to Thread Lubricants in Automotive Applications

Learn about our latest products and discounts through SMS or email

_1739170575968.webp)

_1743990790013.webp)