- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Is the Difference between Titanium and Titanium Alloy?

Titanium and titanium alloys are regularly befuddled, but they have unmistakable characteristics that set them apart. Immaculate titanium is a single-element metal known for its exceptional strength-to-weight proportion, corrosion resistance, and biocompatibility. On the other hand, titanium combinations are built materials that combine titanium with other components like aluminum, vanadium, or molybdenum to upgrade particular properties. These alloys have made strides in quality, strength, and warm resistance compared to unadulterated titanium, making them perfect for applications in aviation, restorative inserts, and mechanical settings. Whereas both materials share titanium's center benefits, the addition of alloying components in titanium alloy pipes permits custom-made execution in requesting situations.

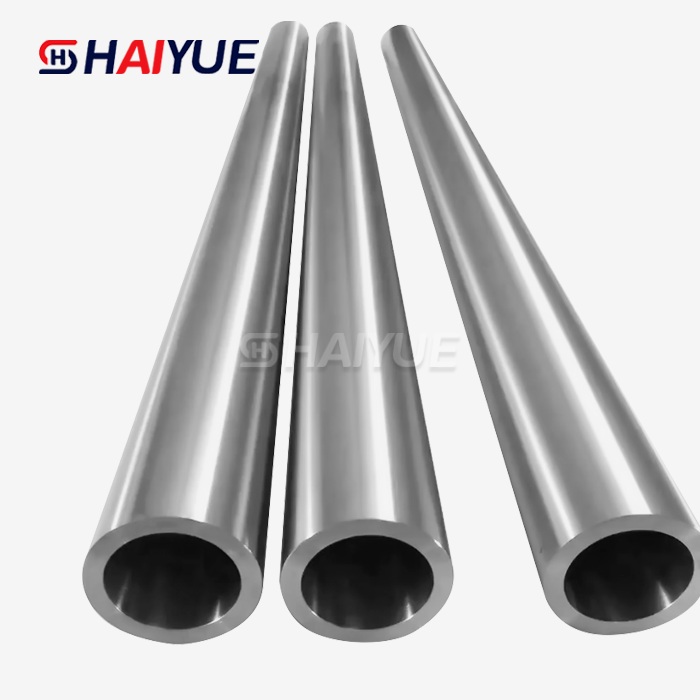

Titanium Alloy Pipe: Composition and Properties

Chemical Composition of Titanium Alloys

Titanium alloy pipes are made from a carefully chosen mix of components, with titanium serving as the essential component. The most common titanium combination utilized in pipe fabricating is Ti-6Al-4V, which contains 6% aluminum and 4% vanadium. This composition strikes an ideal balance between quality and workability, making it a flexible choice for different applications.

Other alloying components may include molybdenum, zirconium, or niobium, each conferring special properties to the last item. For instance, molybdenum enhances corrosion resistance, while zirconium progresses weldability. The exact composition of titanium alloy pipes can be tailored to meet particular industry necessities, guaranteeing ideal execution in assorted situations.

Mechanical Properties of Titanium Alloy Pipes

Titanium alloy pipes boast an impressive cluster of mechanical properties that set them apart from their unadulterated titanium partners. The addition of alloying components essentially upgrades the material's quality, permitting titanium alloy pipes to withstand higher weights and loads. This expanded quality does not come at the cost of weight, as titanium alloys keep up a surprisingly low thickness compared to other high-strength materials.

The surrender quality of titanium alloy pipes typically ranges from 800 to 1,100 MPa, depending on the particular alloy and warm treatment. This uncommon strength-to-weight proportion makes titanium alloy pipes a perfect choice for applications where weight lessening is pivotal, such as in aviation or seaward businesses.

Corrosion Resistance and Durability

One of the most compelling qualities of titanium alloy pipes is their outstanding erosion resistance. The alloying components contribute to the arrangement of a steady, defensive oxide layer on the surface of the pipe, protecting it from forceful situations. This inborn corrosion resistance makes titanium alloy pipes reasonable for use in unforgiving conditions, including seawater, chemical processing plants, and oil and gas extraction offices.

Titanium alloy pipes illustrate surprising resistance to setting, crevice corrosion, and stress erosion splitting. This strength translates to extended benefit life and decreased support prerequisites, making them a cost-effective choice for long-term establishments. Furthermore, the corrosion resistance of titanium alloy pipes kills the requirement for defensive coatings or linings, disentangling establishment and lessening overall framework complexity.

Applications and Advantages of Titanium Alloy Pipes

Aerospace and Aviation Industry

The aerospace and aviation sectors have embraced titanium alloy pipes for their unparalleled combination of strength, light weight, and resistance to extreme temperatures. In aircraft hydraulic systems, titanium alloy pipes play a crucial role in transporting fluids under high pressure while minimizing overall weight. The material's ability to withstand the rigors of high-altitude flight, including rapid temperature changes and exposure to corrosive de-icing fluids, makes it an indispensable component in modern aircraft design.

Space exploration vehicles and satellites also benefit from titanium alloy pipes. The material's high strength-to-weight ratio allows for the construction of robust yet lightweight propulsion systems and fuel lines. Furthermore, titanium alloy pipes' resistance to the harsh conditions of space, including extreme temperature fluctuations and exposure to radiation, ensures the longevity and reliability of critical spacecraft components.

Chemical and Petrochemical Industries

In the chemical and petrochemical sectors, titanium alloy pipes have found widespread application due to their exceptional corrosion resistance and durability. These pipes are capable of handling a wide range of aggressive chemicals, including acids, chlorides, and oxidizing agents, without degradation or contamination of the transported fluids.

Titanium alloy pipes are especially important in desalination plants, where they resist the destructive impacts of seawater and brine arrangements. Their use in heat exchangers and condensers in these offices guarantees productive warm exchange and long-term reliability. In petrochemical refineries, titanium alloy pipes are utilized in forms including destructive hydrocarbons, sulfur compounds, and other responsive substances, where their resistance to both high temperatures and chemical assault is fundamental.

Biomedical and Pharmaceutical Applications

The biocompatibility of titanium alloys has led to their adoption in various biomedical and pharmaceutical applications. In the production of medical implants, titanium alloy pipes are used to create devices such as artificial joints, dental implants, and cardiovascular stents. The material's ability to integrate with human tissue without causing adverse reactions makes it an ideal choice for long-term implantation.

In pharmaceutical manufacturing, titanium alloy pipes are prized for their cleanliness and resistance to bacterial growth. These pipes can be easily sterilized and do not leach contaminants into sensitive drug formulations. The use of titanium alloy pipes in bioreactors and fermentation vessels ensures the purity and consistency of pharmaceutical products, meeting the stringent requirements of regulatory agencies.

Manufacturing Processes and Quality Control for Titanium Alloy Pipes

Extrusion and Drawing Techniques

The production of titanium alloy pipes involves sophisticated manufacturing processes that ensure optimal material properties and dimensional accuracy. Extrusion is a common method used to create seamless titanium alloy pipes. In this process, a heated titanium alloy billet is forced through a die to form a continuous pipe. The extrusion process allows for precise control over the pipe's wall thickness and internal diameter, resulting in consistent product quality.

Heat Treatment and Surface Finishing

Heat treatment plays a crucial role in optimizing the mechanical properties of titanium alloy pipes. Solution treatment and aging processes are commonly applied to achieve the desired balance of strength, ductility, and toughness. These heat treatments involve carefully controlled heating and cooling cycles that alter the microstructure of the alloy, resulting in improved performance characteristics.

Non-Destructive Testing and Quality Assurance

Ensuring the integrity and reliability of titanium alloy pipes requires rigorous quality control measures. Non-destructive testing (NDT) methods are extensively used to inspect pipes for defects without compromising their structural integrity. Ultrasonic testing is a common NDT technique employed to detect internal flaws, such as inclusions or voids, that may affect the pipe's performance.

Conclusion

Titanium alloy pipes represent a pinnacle of materials engineering, offering an unparalleled combination of strength, corrosion resistance, and versatility. From the depths of the ocean to the reaches of space, these remarkable components continue to push the boundaries of what's possible in various industries. As technology advances and new challenges emerge, titanium alloy pipes will undoubtedly play an increasingly vital role in shaping our future.

For those seeking high-quality titanium alloy pipes and related products, Baoji Haiyue stands ready to meet your needs with our extensive range of titanium and specialty metal solutions. Our commitment to quality, innovation, and customer satisfaction ensures that you receive products that exceed your expectations. To learn more about our titanium alloy offerings or to discuss your specific requirements, please don't hesitate to contact us at Jolina@bjhyti.com. Let us help you harness the power of titanium alloys for your next project or application.

Main Products

Applied Industries

Be used in a wide range of industries.

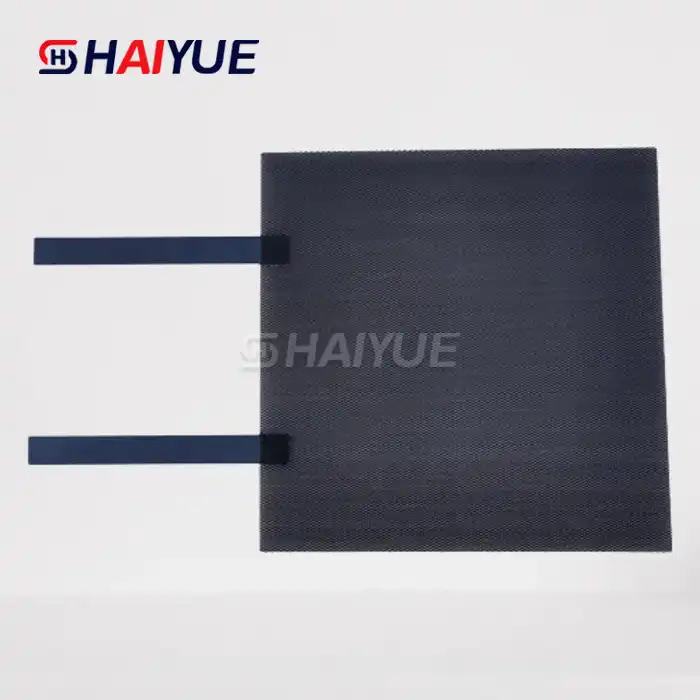

Electrolytic copper foil manufacturing industry

Hydrometallurgy industry

Sewage treatment industry

Cyclone electrolysis industry

Etching liquid electrolysis recovery industry

Electrolytic sodium hypochlorite industry

References

1. Lutjering, G., & Williams, J. C. (2007). Titanium (2nd ed.). Springer-Verlag Berlin Heidelberg.

2. Donachie, M. J. (2000). Titanium: A Technical Guide (2nd ed.). ASM International.

3. Peters, M., Kumpfert, J., Ward, C. H., & Leyens, C. (2003). Titanium Alloys for Aerospace Applications. Advanced Engineering Materials, 5(6), 419-427.

4. Rack, H. J., & Qazi, J. I. (2006). Titanium alloys for biomedical applications. Materials Science and Engineering: C, 26(8), 1269-1277.

5. Boyer, R. R. (1996). An overview on the use of titanium in the aerospace industry. Materials Science and Engineering: A, 213(1-2), 103-114.

Learn about our latest products and discounts through SMS or email

_1738825878786.webp)

_1743059483810.webp)