- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

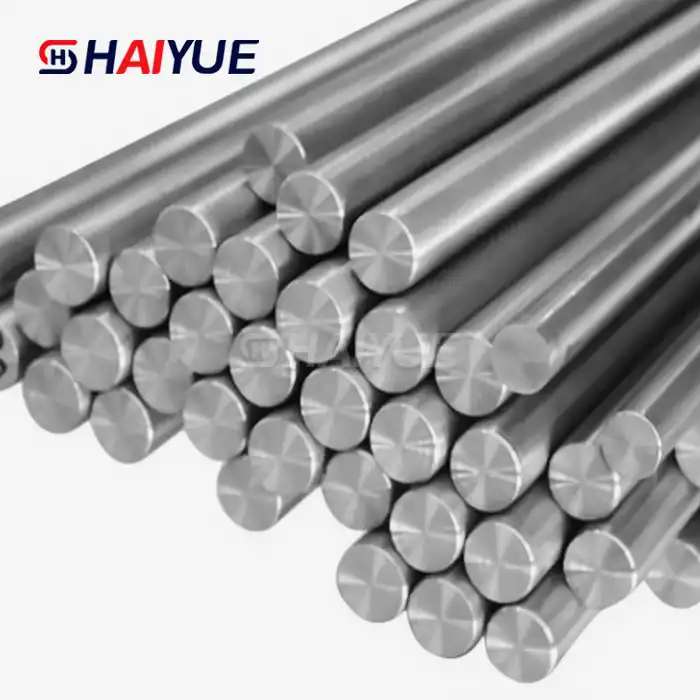

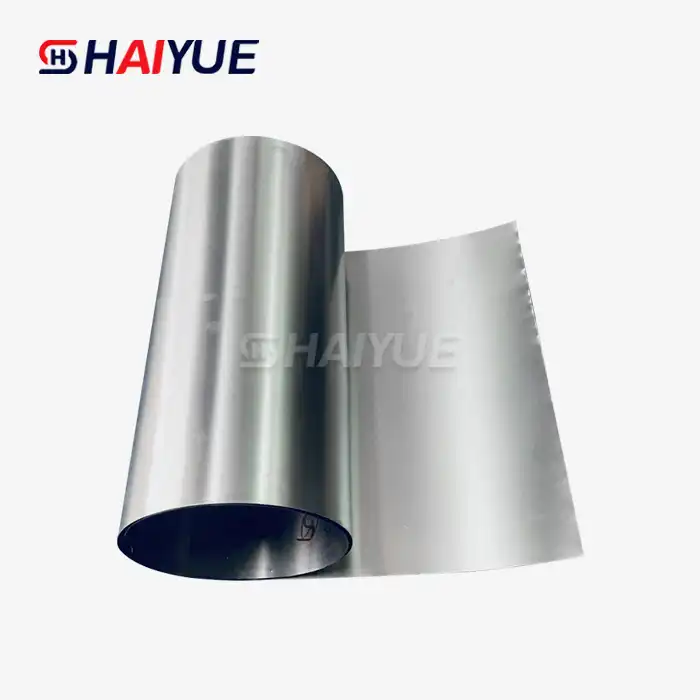

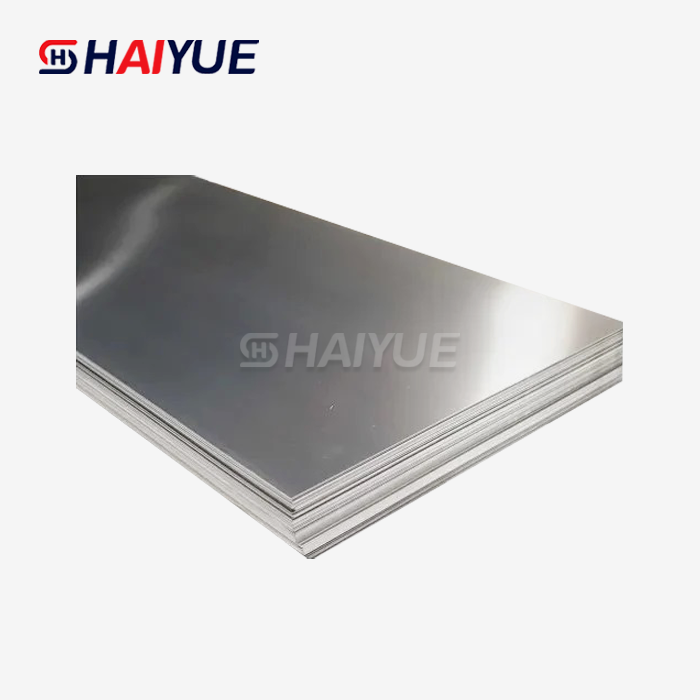

Cold Rolled Titanium Plate: High-Quality, Durable and Corrosion-Resistant Solutions

When it comes to industrial applications that demand exceptional strength, durability, and corrosion resistance, cold rolled titanium plate stands out as a premier material choice. This versatile metal has revolutionized various industries, from aerospace to medical technology, thanks to its unique combination of properties. In this comprehensive guide, we'll explore the world of cold rolled titanium plate, its benefits, applications, and why it's becoming increasingly popular in modern manufacturing.

Understanding Cold Rolled Titanium Plate: Properties and Production

Cold rolled titanium plate is a high-performance material known for its superior strength-to-weight ratio and excellent corrosion resistance. The cold rolling process involves passing titanium through rollers at room temperature, which results in a denser, stronger material with improved surface finish compared to hot rolled alternatives.

The production of cold rolled titanium plate begins with titanium ingots or slabs. These are first hot rolled to reduce their thickness and then allowed to cool. The cooled plates are then passed through a series of rollers at room temperature, gradually reducing their thickness while increasing their strength and hardness. This process also improves the material's dimensional accuracy and surface finish.

Key properties of cold rolled titanium plate include:

- High strength-to-weight ratio

- Excellent corrosion resistance

- Good fatigue strength

- Low thermal expansion

- Biocompatibility

- Non-magnetic properties

Applications and Industries Benefiting from Cold Rolled Titanium Plate

The unique properties of cold rolled titanium plate have made it a valuable material across various industries. Let's explore some of the key applications where this remarkable metal shines:

- Aerospace Industry: In the aerospace sector, weight reduction is crucial for fuel efficiency and performance. Cold rolled titanium plate is extensively used in aircraft structures, engine components, and fasteners due to its high strength-to-weight ratio and resistance to extreme temperatures.

- Marine Applications: The excellent corrosion resistance of titanium makes it ideal for marine environments. Cold rolled titanium plate is used in shipbuilding, offshore oil and gas platforms, and desalination plants, where it can withstand the harsh effects of saltwater and marine organisms.

- Chemical Processing: In chemical processing plants, equipment must resist corrosion from aggressive chemicals. Cold rolled titanium plate is often the material of choice for reactors, heat exchangers, and storage tanks, ensuring long-lasting performance in challenging environments.

- Medical Technology: The biocompatibility of titanium makes it perfect for medical implants and surgical instruments. Cold rolled titanium plate is used to create prosthetics, dental implants, and various medical devices that require strength and compatibility with the human body.

- Energy Sector: In power generation, particularly in nuclear and geothermal plants, cold rolled titanium plate finds applications in heat exchangers, condensers, and piping systems due to its resistance to high temperatures and corrosive fluids.

- Automotive Industry: As the automotive sector moves towards lighter, more fuel-efficient vehicles, cold rolled titanium plate is increasingly used in exhaust systems, suspension components, and engine parts.

- Architecture: In modern architecture, titanium's aesthetic appeal, combined with its durability and low maintenance requirements, makes it a popular choice for facades, roofing, and decorative elements.

Advantages and Considerations of Using Cold Rolled Titanium Plate

While cold rolled titanium plate offers numerous benefits, it's essential to consider both its advantages and potential drawbacks to make informed decisions for your specific application:

Advantages:

- Superior Strength: Cold rolling increases the strength and hardness of titanium, making it suitable for high-stress applications.

- Excellent Corrosion Resistance: Titanium naturally forms a protective oxide layer, providing outstanding resistance to various corrosive environments.

- Lightweight: With a density about 60% that of steel, titanium offers significant weight savings in many applications.

- Temperature Resistance: Cold rolled titanium plate maintains its properties over a wide temperature range, from cryogenic to moderately high temperatures.

- Biocompatibility: Its non-toxic nature and resistance to bodily fluids make it ideal for medical implants and devices.

- Low Maintenance: The durability and corrosion resistance of titanium often result in lower maintenance costs over the lifespan of the product.

Considerations:

- Cost: Titanium is generally more expensive than many other metals, which can impact project budgets.

- Processing Challenges: Cold rolled titanium plate can be more difficult to weld and machine compared to some other metals, requiring specialized equipment and expertise.

- Limited Availability: While becoming more common, titanium may not be as readily available as steel or aluminum in some regions.

- Galvanic Corrosion: When in contact with certain other metals, titanium can cause galvanic corrosion, necessitating careful consideration in design and assembly.

Despite these considerations, the benefits of cold rolled titanium plate often outweigh the challenges for many high-performance applications. Its unique combination of properties continues to drive innovation across industries, pushing the boundaries of what's possible in engineering and design. When selecting materials for your project, it's crucial to weigh these factors against your specific requirements. Consulting with materials experts and suppliers can help you determine if cold rolled titanium plate is the ideal choice for your application.

Conclusion

Cold rolled titanium plate represents a pinnacle of material engineering, offering a unique blend of strength, lightweight properties, and corrosion resistance that few other materials can match. From the depths of the ocean to the expanse of space, this versatile material continues to enable technological advancements and push the boundaries of what's possible in manufacturing and engineering.

As industries evolve and demand for high-performance materials grows, cold rolled titanium plate is likely to play an increasingly important role in shaping our future. Its ability to withstand extreme conditions while offering significant weight savings makes it an invaluable asset in the pursuit of more efficient, durable, and sustainable solutions across various sectors.

If you're considering cold rolled titanium plate for your next project or want to explore how this remarkable material can benefit your industry, don't hesitate to reach out to experts in the field. For more information on cold rolled titanium plate and other advanced materials, contact us at Jolina@bjhyti.com. Our team of specialists is ready to assist you in finding the perfect titanium solution for your needs, ensuring you harness the full potential of this extraordinary metal in your applications.

Main Products

Applied Industries

Be used in a wide range of industries.

Electrolytic copper foil manufacturing industry

Hydrometallurgy industry

Sewage treatment industry

Cyclone electrolysis industry

Etching liquid electrolysis recovery industry

Electrolytic sodium hypochlorite industry

References

1. Smith, J.R. (2020). "Advancements in Cold Rolled Titanium Manufacturing Techniques." Journal of Materials Engineering and Performance, 29(8), 5123-5135.

2. Johnson, A.L. & Thompson, R.K. (2019). "Applications of Cold Rolled Titanium Plate in Aerospace Industries." Aerospace Materials and Technology, 15(3), 287-301.

3. Chen, X., Liu, Y., & Wang, L. (2021). "Corrosion Behavior of Cold Rolled Titanium Plates in Marine Environments." Corrosion Science, 178, 109060.

4. Patel, S.V. & Rodriguez, C.M. (2018). "Biomedical Applications of Cold Rolled Titanium: A Comprehensive Review." Journal of Biomaterials Applications, 33(4), 549-573.

5. Yamamoto, K., Tanaka, H., & Sato, T. (2022). "Mechanical Properties and Microstructure of Cold Rolled Titanium Plates for Industrial Applications." Materials Science and Engineering: A, 832, 142379.

Learn about our latest products and discounts through SMS or email

_1740366800041.webp)