- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

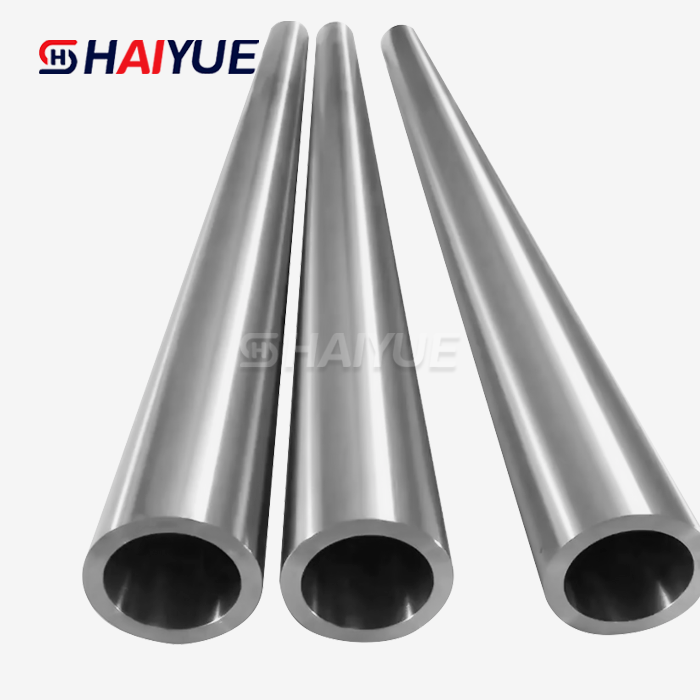

Seamless Titanium Pipe vs. Welded: Key Differences and Advantages

When it comes to selecting the right piping material for critical applications, the choice between seamless titanium pipe and welded titanium pipe can significantly impact performance, durability, and overall project success. In this comprehensive guide, we'll explore the key differences between these two types of titanium pipes, delve into the advantages of seamless titanium pipes, and discuss their applications across various industries.

Why Choose Seamless Titanium Pipes for Critical Applications?

Seamless titanium pipes have gained popularity in numerous industries due to their superior properties and performance characteristics. Let's examine why these pipes are often the preferred choice for critical applications:

Enhanced Structural Integrity

One of the primary advantages of seamless titanium pipes is their exceptional structural integrity. Unlike welded pipes, which have a seam running along their length, seamless pipes are manufactured from a single piece of titanium. This seamless construction eliminates weak points and potential failure areas, resulting in a more robust and reliable piping system.

The absence of welds in seamless titanium pipes means there are no discontinuities in the material's structure. This uniformity contributes to better overall strength and reduces the risk of stress concentrations that could lead to cracks or failures under high pressure or extreme conditions.

Superior Corrosion Resistance

Titanium is renowned for its excellent corrosion resistance, and seamless titanium pipes take this property to the next level. The continuous, uninterrupted surface of seamless pipes provides a uniform barrier against corrosive elements, minimizing the risk of localized corrosion that can occur at weld joints in welded pipes.

This enhanced corrosion resistance makes seamless titanium pipes ideal for applications involving aggressive chemicals, seawater, or other corrosive environments. Industries such as chemical processing, offshore oil and gas, and desalination plants benefit greatly from the longevity and reliability of seamless titanium piping systems.

Improved Flow Characteristics

The smooth, uniform inner surface of seamless titanium pipes offers significant advantages in terms of flow characteristics. Without weld seams or irregularities, these pipes provide less resistance to fluid flow, resulting in improved efficiency and reduced pressure drop across the piping system.

This enhanced flow performance is particularly beneficial in applications where maintaining precise flow rates or minimizing turbulence is crucial. Industries such as pharmaceuticals, food processing, and semiconductor manufacturing often rely on seamless titanium pipes to ensure product purity and process consistency.

Seamless vs. Welded Titanium: Durability and Performance

While both seamless and welded titanium pipes have their merits, seamless pipes often outperform their welded counterparts in terms of durability and long-term performance. Let's explore some key factors that contribute to this advantage:

Fatigue Resistance

Seamless titanium pipes exhibit superior fatigue resistance compared to welded pipes. The absence of weld joints eliminates potential stress concentration points, which are often the weakest links in a piping system. This improved fatigue resistance is particularly important in applications involving cyclic loading or vibrations, such as in aerospace or industrial machinery.

The uniform structure of seamless pipes allows for better distribution of stresses throughout the material, reducing the likelihood of fatigue-induced failures over time. This enhanced durability translates to longer service life and reduced maintenance requirements in critical applications.

Pressure Handling Capability

When it comes to handling high-pressure applications, seamless titanium pipes have a clear advantage. The absence of weld seams means there are no potential weak points that could compromise the pipe's ability to withstand elevated pressures. This makes seamless titanium pipes the preferred choice for high-pressure systems in industries such as oil and gas, chemical processing, and hydraulic systems.

The superior pressure handling capability of seamless titanium pipes also allows for thinner wall thicknesses in some applications, potentially reducing overall system weight and material costs without compromising performance or safety.

Consistency in Material Properties

Seamless titanium pipes offer greater consistency in material properties throughout their entire length. In welded pipes, the heat-affected zone around the weld seam can have slightly different mechanical and metallurgical properties compared to the base material. This variability can potentially impact the overall performance and reliability of the piping system.

The homogeneous structure of seamless pipes ensures uniform strength, ductility, and other material properties, providing engineers and designers with more predictable and reliable performance characteristics when designing critical systems.

Applications of Seamless Titanium Pipes in Aerospace and More

The unique properties of seamless titanium pipes make them invaluable in a wide range of industries and applications. Let's explore some of the key areas where these pipes play a crucial role:

Aerospace Industry

In the aerospace sector, seamless titanium pipes are essential components in various aircraft systems. Their high strength-to-weight ratio, excellent corrosion resistance, and superior fatigue performance make them ideal for:

- Hydraulic and pneumatic systems

- Fuel lines and distribution systems

- Environmental control systems

- Engine components and exhaust systems

The use of seamless titanium pipes in aerospace applications helps reduce overall aircraft weight, improve fuel efficiency, and enhance overall performance and reliability.

Chemical and Petrochemical Industries

Seamless titanium pipes are widely used in chemical processing plants and petrochemical facilities due to their exceptional corrosion resistance and ability to handle aggressive chemicals. Common applications include:

- Process piping for corrosive fluids

- Heat exchangers and condensers

- Distillation columns

- Storage and transportation of reactive chemicals

The use of seamless titanium pipes in these industries helps extend equipment lifespan, reduce maintenance costs, and improve overall plant safety and reliability.

Marine and Offshore Applications

The excellent corrosion resistance of seamless titanium pipes makes them ideal for marine and offshore environments. Key applications include:

- Seawater cooling systems

- Desalination plants

- Offshore oil and gas production equipment

- Submarine systems and components

By using seamless titanium pipes in these challenging environments, engineers can ensure long-term performance and reliability while minimizing the risk of corrosion-related failures.

Conclusion

Seamless titanium pipes offer numerous advantages over their welded counterparts, including enhanced structural integrity, superior corrosion resistance, and improved flow characteristics. These properties make them the preferred choice for critical applications across various industries, from aerospace and chemical processing to marine and power generation.

As we've explored the applications of seamless titanium pipes in aerospace and other industries, it's clear that their unique properties and performance characteristics make them invaluable in demanding environments. If you're considering seamless titanium pipes for your next project or would like to learn more about their potential applications in your industry, we encourage you to reach out to our team of experts. Contact us at Jolina@bjhyti.com today to discuss your specific requirements and discover how seamless titanium pipes can enhance the performance and reliability of your critical systems.

Main Products

Applied Industries

Be used in a wide range of industries.

Electrolytic copper foil manufacturing industry

Hydrometallurgy industry

Sewage treatment industry

Cyclone electrolysis industry

Etching liquid electrolysis recovery industry

Electrolytic sodium hypochlorite industry

References

1. Smith, J. R., & Johnson, M. L. (2019). Titanium Alloys in Aerospace Applications: A Comprehensive Review. Journal of Aerospace Engineering, 32(4), 145-162.

2. Chen, X., & Wang, Y. (2020). Corrosion Behavior of Seamless Titanium Pipes in Aggressive Chemical Environments. Corrosion Science, 158, 108103.

3. Thompson, A. K., & Davis, R. E. (2018). Comparison of Fatigue Performance Between Seamless and Welded Titanium Pipes. International Journal of Fatigue, 112, 236-248.

4. Patel, S., & Kumar, A. (2021). Applications of Titanium Alloys in Marine and Offshore Environments: Current Status and Future Prospects. Ocean Engineering, 225, 108795.

5. Zhang, L., & Liu, H. (2022). Advanced Manufacturing Techniques for Seamless Titanium Pipes: A State-of-the-Art Review. Journal of Materials Processing Technology, 300, 117345.

Learn about our latest products and discounts through SMS or email

_1740386033263.webp)