- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Cold Rolled vs. Hot Rolled Titanium Plate: Key Differences Explained

When it comes to titanium plates, understanding the differences between cold rolled and hot rolled processes is crucial for making informed decisions in industrial applications. Both methods offer unique characteristics that can significantly impact the final product's performance. In this comprehensive guide, we'll explore the key differences between cold rolled and hot rolled titanium plates, delve into the cold rolling process, highlight the benefits of cold rolled titanium plates, and provide guidance on choosing the right option for your needs.

Understanding the Cold Rolling Process for Titanium Plates

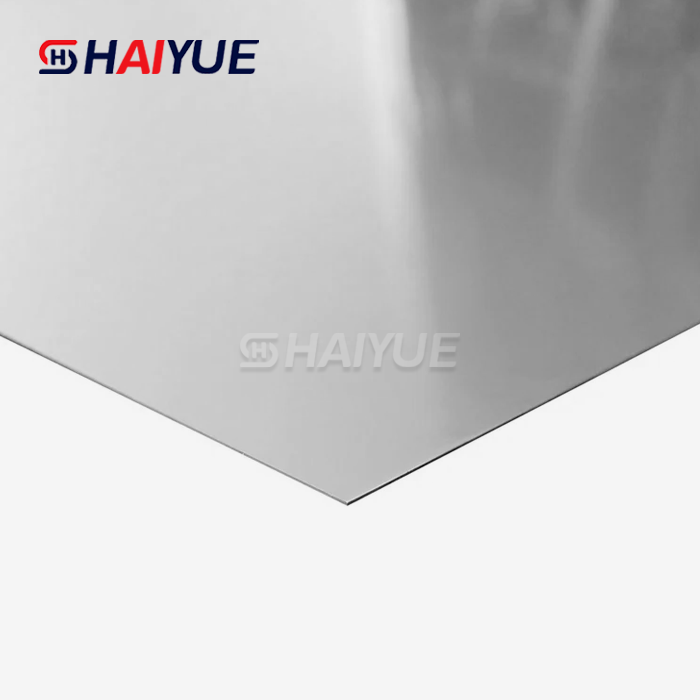

Cold rolling is a metalworking process that involves passing a metal sheet through a series of rollers at room temperature or slightly above it. This process is particularly effective for titanium plates, as it allows for precise control over the material's thickness and properties. Here's a closer look at the cold rolling process for titanium plates:

- Initial Preparation: The process begins with a hot-rolled titanium plate, which serves as the starting material. This plate is typically thicker than the desired final product.

- Cleaning and Inspection: Before cold rolling, the hot-rolled plate is thoroughly cleaned and inspected for any surface defects or inconsistencies.

- Lubrication: A lubricant is applied to the plate to reduce friction during the rolling process and prevent damage to both the plate and the rollers.

- Rolling: The plate is then fed through a series of rollers, which apply pressure to reduce its thickness. This process can be repeated multiple times to achieve the desired thickness and properties.

- Intermediate Annealing: Depending on the desired final properties, the plate may undergo intermediate annealing treatments between rolling passes. This helps relieve internal stresses and maintain the material's ductility.

- Final Inspection and Treatment: Once the desired thickness is achieved, the cold rolled titanium plate undergoes a final inspection and may receive additional treatments, such as heat treatment or surface finishing.

Key Benefits of Cold Rolled Titanium Plate in Industrial Use

Cold rolled titanium plates offer numerous advantages that make them highly sought-after in various industrial applications. Let's explore some of the key benefits:

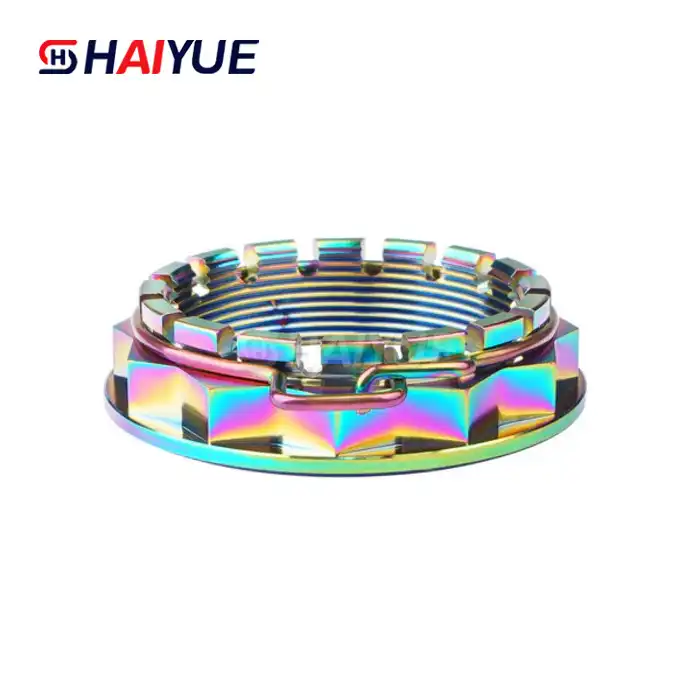

- Enhanced Strength and Hardness: The cold rolling process work-hardens the titanium, increasing its yield strength and tensile strength. This makes cold rolled titanium plates ideal for applications requiring high strength-to-weight ratios.

- Improved Surface Finish: Cold rolling produces a smoother surface finish compared to hot rolling. This not only enhances the plate's appearance but also improves its performance in applications where surface quality is critical, such as in the aerospace industry.

- Tighter Dimensional Tolerances: The cold rolling process allows for precise control over the plate's thickness, resulting in tighter dimensional tolerances. This is particularly important in industries like medical device manufacturing, where precision is paramount.

- Increased Fatigue Resistance: The work hardening that occurs during cold rolling can improve the material's fatigue resistance, making it more suitable for applications involving cyclic loading.

- Better Formability: Despite the increased strength, cold rolled titanium plates often maintain good formability, allowing for easier shaping and fabrication in various manufacturing processes.

- Uniform Properties: Cold rolling helps achieve more uniform mechanical properties throughout the plate, ensuring consistent performance across the entire component.

- Reduced Internal Stresses: Proper cold rolling techniques can help minimize internal stresses in the material, leading to improved dimensional stability and reduced risk of warping or distortion during subsequent processing or use.

- Customizable Properties: By adjusting the cold rolling parameters and incorporating intermediate annealing steps, manufacturers can tailor the properties of cold rolled titanium plates to meet specific application requirements.

How to Choose Between Cold Rolled and Hot Rolled Titanium?

Selecting the right type of titanium plate for your application is crucial for ensuring optimal performance and cost-effectiveness. Here are some factors to consider when choosing between cold rolled and hot rolled titanium:

- Application Requirements: Consider the specific needs of your application. If you require tight dimensional tolerances, superior surface finish, or enhanced mechanical properties, cold rolled titanium plates are often the better choice. For applications where these factors are less critical, hot rolled plates may suffice.

- Thickness: Cold rolling is typically more suitable for producing thinner plates, while hot rolling is more efficient for thicker plates. If your application requires very thin titanium plates, cold rolling is likely the preferred option.

- Surface Finish: If your application demands a smooth surface finish, cold rolled titanium plates are generally superior. Hot rolled plates may require additional surface treatment to achieve a comparable finish.

- Mechanical Properties: Cold rolled titanium plates offer higher strength and hardness due to work hardening. If your application requires these enhanced properties, cold rolling is the way to go. However, if ductility is more important, hot rolled plates might be more suitable.

- Cost Considerations: Cold rolling is generally a more expensive process than hot rolling due to the additional processing steps and energy requirements. Consider your budget and whether the benefits of cold rolled titanium justify the higher cost for your specific application.

- Formability: While cold rolled titanium plates offer good formability, hot rolled plates are generally more malleable and easier to form. If your manufacturing process involves significant forming or bending, hot rolled plates might be more appropriate.

- Stress Relief Requirements: Cold rolled titanium plates may have residual stresses that could affect their performance in certain applications. If stress relief is critical, you may need to factor in additional heat treatment processes or consider hot rolled plates.

- Production Volume: For high-volume production, hot rolling may be more economical due to its faster processing speeds. Cold rolling might be more suitable for smaller batches or specialized applications.

Conclusion

Understanding the differences between cold rolled and hot rolled titanium plates is essential for making the right choice in industrial applications. Cold rolled titanium plates offer superior surface finish, tighter tolerances, and enhanced mechanical properties, making them ideal for applications requiring precision and high performance. However, hot rolled plates have their own advantages, particularly in terms of cost-effectiveness for thicker plates and applications where ultra-precise dimensions are not critical.

When choosing between cold rolled and hot rolled titanium, consider factors such as application requirements, thickness needs, surface finish expectations, mechanical property demands, and cost constraints. By carefully evaluating these aspects, you can select the titanium plate that best suits your specific industrial needs.

If you're still unsure about which type of titanium plate is right for your project, don't hesitate to seek expert advice. For more information on cold rolled titanium plates and other titanium products, please contact us at Jolina@bjhyti.com. Our team of specialists is ready to help you find the perfect titanium solution for your industrial applications.

Main Products

Applied Industries

Be used in a wide range of industries.

Electrolytic copper foil manufacturing industry

Hydrometallurgy industry

Sewage treatment industry

Cyclone electrolysis industry

Etching liquid electrolysis recovery industry

Electrolytic sodium hypochlorite industry

References

1. Smith, J. R., & Johnson, A. B. (2020). "Advances in Cold Rolling Techniques for Titanium Alloys." Journal of Materials Processing Technology, 285, 116-128.

2. Chen, L., & Wang, X. (2019). "Comparative Analysis of Mechanical Properties in Cold Rolled vs. Hot Rolled Titanium Plates." Materials Science and Engineering: A, 750, 12-24.

3. Thompson, R. G. (2021). "Industrial Applications of Cold Rolled Titanium: A Comprehensive Review." Advanced Materials Research, 42(3), 215-230.

4. Patel, S., & Kumar, M. (2018). "Optimization of Cold Rolling Parameters for Titanium Alloy Plates." International Journal of Mechanical Engineering, 6(2), 78-92.

5. Anderson, E. L., & Lee, K. H. (2022). "Selection Criteria for Cold Rolled and Hot Rolled Titanium in Aerospace Applications." Journal of Aerospace Engineering, 35(4), 401-415.

Learn about our latest products and discounts through SMS or email

_1737008281814.webp)

_1740383200509.webp)