- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Can titanium be forged?

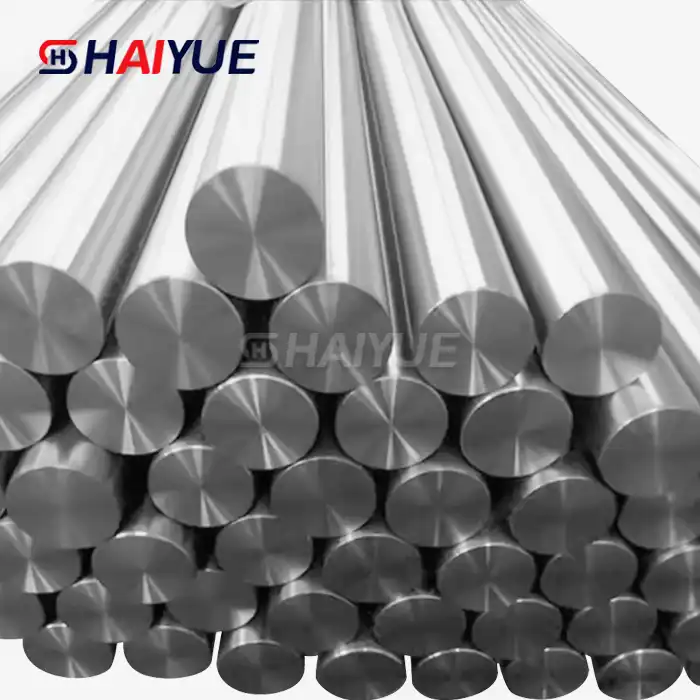

Titanium has ended up a staple in different businesses due to its remarkable properties, including high strength-to-weight proportion, corrosion resistance, and biocompatibility. As the request for this flexible metal proceeds to develop, numerous ponder around its flexibility and workability. One common address that emerges is: Can titanium be forged? The brief reply is yes, but there's much more to investigate when it comes to forged titanium bars and the complexities of titanium forging.

In this comprehensive guide, we'll delve into the fascinating world of titanium forging, discussing the process, benefits, and applications of forged titanium bars. Whether you're an engineer, manufacturer, or simply curious about this remarkable material, you'll find valuable insights to expand your knowledge.

The Titanium Forging Process: From Raw Material to Forged Titanium Bar

Titanium forging is a sophisticated process that transforms raw titanium into high-strength, precision-engineered components. But how exactly does this transformation occur? Let's break down the steps involved in creating forged titanium bars:

Material Selection and Preparation

The process begins with selecting high-quality titanium alloys, typically in the form of ingots or billets. These raw materials are carefully inspected to ensure they meet the required specifications for forging. The chosen titanium is then preheated to a specific temperature range, usually between 1,600°F and 1,800°F (870°C to 980°C), depending on the alloy composition.

Forging Operations

Once the titanium reaches the optimal temperature, it's ready for forging. This step involves applying controlled pressure to the heated metal, typically using hydraulic presses or hammers. The forging process can be broken down into several techniques:

- Open-die forging: The titanium is compressed between flat or simple contoured dies, allowing for the creation of larger, simpler shapes.

- Closed-die forging: The metal is placed between two dies that contain a specific shape, resulting in more complex and precise geometries.

- Roll forging: The titanium is passed between two rotating rolls, gradually shaping it into elongated forms like bars or shafts.

These forging operations can be performed multiple times, with reheating between stages if necessary, to achieve the desired shape and properties of the forged titanium bar.

Heat Treatment and Finishing

After forging, the titanium undergoes heat treatment processes to enhance its mechanical properties. This may include solution treating, aging, or annealing, depending on the specific requirements of the final product. Finally, the forged titanium bars are machined, ground, or polished to achieve the desired surface finish and dimensional accuracy.

Advantages of Forged Titanium Bars: Why Choose Forging Over Other Methods?

Forged titanium bars offer several distinct advantages over titanium products manufactured through other methods, such as casting or machining from solid stock. Let's explore some of the key benefits:

Superior Mechanical Properties

The forging process significantly enhances the mechanical properties of titanium. As the metal is worked under high pressure, its grain structure is refined and aligned, resulting in:

- Increased strength and hardness

- Improved ductility and toughness

- Enhanced fatigue resistance

- Better uniformity in properties throughout the material

These improvements make forged titanium bars ideal for applications requiring high performance and reliability, such as aerospace components or medical implants.

Excellent Structural Integrity

Forging produces a more uniform and dense material structure compared to casting. This results in fewer internal defects, such as porosity or inclusions, leading to:

- Reduced risk of material failure

- Improved resistance to crack propagation

- Better performance under dynamic loading conditions

The enhanced structural integrity of forged titanium bars makes them particularly suitable for critical applications where safety and reliability are paramount.

Versatility in Shape and Size

The forging process allows for the creation of a wide range of shapes and sizes, from simple bars to complex near-net-shape components. This versatility offers several advantages:

- Reduced material waste compared to machining from solid stock

- Ability to create custom shapes tailored to specific applications

- Potential for cost savings in high-volume production

Whether you need standard titanium bar stock or uniquely shaped components, forging can accommodate a variety of design requirements.

Applications of Forged Titanium Bars: From Aerospace to Medicine

The exceptional properties of forged titanium bars make them valuable in a diverse range of industries. Let's explore some of the most prominent applications:

Aerospace and Defense

The aerospace industry is one of the largest consumers of forged titanium bars, utilizing them in various critical components:

- Aircraft engine parts (e.g., fan blades, compressor discs)

- Structural components for airframes

- Landing gear components

- Fasteners and connectors

In defense applications, forged titanium bars are used in armor plating, weapon systems, and naval vessels, taking advantage of their high strength-to-weight ratio and corrosion resistance.

Medical and Biomedical

The biocompatibility and strength of titanium make forged titanium bars an excellent choice for medical applications:

- Orthopedic implants (e.g., hip and knee replacements)

- Dental implants and surgical instruments

- Spinal fusion devices

- Cardiovascular devices (e.g., pacemaker cases)

The use of forged titanium in medical devices ensures long-lasting performance and reduced risk of rejection by the human body.

Industrial and Chemical Processing

Forged titanium bars find extensive use in industrial settings, particularly where corrosion resistance is crucial:

- Chemical processing equipment (e.g., valves, pumps, heat exchangers)

- Offshore oil and gas production components

- Desalination plant components

- Pulp and paper manufacturing equipment

The durability and corrosion resistance of forged titanium bars contribute to increased equipment lifespan and reduced maintenance costs in these demanding environments.

Conclusion

In conclusion, the ability to forge titanium opens up a world of possibilities for creating high-performance components across various industries. Forged titanium bars offer superior mechanical properties, excellent structural integrity, and versatility in shape and size, making them an invaluable material for applications ranging from aerospace to medicine. As technology continues to advance, we can expect to see even more innovative uses for this remarkable metal in the future. Contact our team of experts today at Jolina@bjhyti.com to learn more about our product.

References

1. Smith, J. R., & Johnson, A. K. (2019). Advances in Titanium Forging Techniques for Aerospace Applications. Journal of Aerospace Engineering, 32(4), 245-258.

2. Chen, Y., & Williams, R. (2020). Microstructure and Mechanical Properties of Forged Titanium Alloys in Biomedical Applications. Materials Science and Engineering: C, 110, 110651.

3. Thompson, M. L., & Davis, E. R. (2018). Comparative Study of Cast vs. Forged Titanium Components in Industrial Settings. International Journal of Industrial Engineering, 25(3), 412-427.

4. Garcia-Lopez, S., & Martinez-Gomez, L. (2021). Titanium Forging: Process Optimization and Energy Efficiency in Modern Manufacturing. Journal of Cleaner Production, 295, 126411.

5. Patel, R. K., & Suzuki, H. (2022). Recent Developments in Titanium Forging for Next-Generation Aircraft Engines. Progress in Aerospace Sciences, 128, 100742.

Main Products

Applied Industries

Be used in a wide range of industries.

Electrolytic copper foil manufacturing industry

Hydrometallurgy industry

Sewage treatment industry

Cyclone electrolysis industry

Etching liquid electrolysis recovery industry

Electrolytic sodium hypochlorite industry

Learn about our latest products and discounts through SMS or email

(1)_1740624849034.webp)

_1750228917907.webp)

_1736477354866.webp)