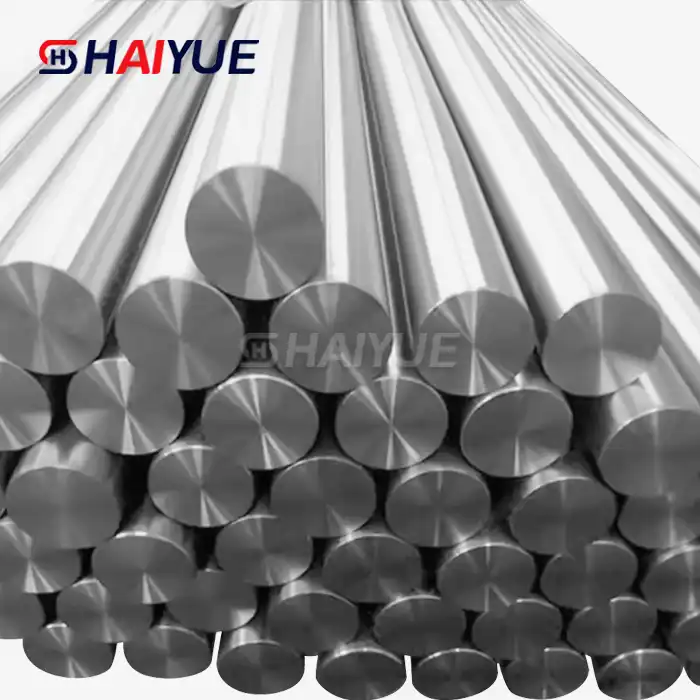

Understanding the Unique Properties of Industrial Grade Titanium Bars

Industrial grade titanium bars are not your normal metal items. They have a special set of characteristics that set them separated from other materials commonly utilized in mechanical applications.

Let's investigate what makes these titanium bars so uncommon:

Exceptional Strength-to-Weight Ratio

One of the most striking highlights of Industrial grade titanium bars is their unimaginable strength-to-weight proportion. In spite of being surprisingly lightweight, these bars display quality comparable to steel. This special combination makes them perfect for applications where both weight lessening and tall quality are vital, such as in aviation building or high-performance car parts.

Corrosion Resistance

Titanium's natural resistance to corrosion is another standout property of industrial grade titanium bars. They form a protective oxide layer when exposed to air or moisture, making them highly resistant to various corrosive environments. This characteristic is particularly valuable in marine applications, chemical processing plants, and other settings where exposure to harsh chemicals or saltwater is common.

High Temperature Performance

Industrial grade titanium bars maintain their strength and structural integrity even at elevated temperatures. This heat resistance makes them suitable for use in high-temperature environments, such as jet engines or industrial furnaces, where other materials might fail or degrade.

These exceptional properties contribute to the growing popularity of industrial grade titanium bars across various industries. As we continue to explore their applications and benefits, it becomes clear why they're considered a game-changer in the world of industrial materials.

Applications of Industrial Grade Titanium Bars in Various Industries

The versatility of industrial grade titanium bars has led to their adoption in a wide range of industries. Let's take a closer look at some of the key sectors where these remarkable materials are making a significant impact:

Aerospace and Aviation

In the aerospace industry, where every gram counts, industrial grade titanium bars have found a natural home. They're used extensively in aircraft structures, engine components, and landing gear systems. The combination of light weight and high strength allows for fuel-efficient designs without compromising on safety or performance.

Medical and Biomedical Applications

The biocompatibility of titanium makes industrial grade titanium bars an great choice for therapeutic inserts and surgical disobedient. From hip substitutions to dental inserts, these bars are changed into life-changing restorative gadgets that are well-tolerated by the human body.

Chemical and Petrochemical Industries

The corrosion resistance of industrial grade titanium bars is particularly valuable in chemical processing plants and oil refineries. They're used in heat exchangers, reaction vessels, and piping systems where exposure to corrosive substances is a constant concern.

Marine and Offshore Applications

In marine environments, where saltwater corrosion is a major challenge, industrial grade titanium bars shine. They're used in shipbuilding, offshore oil and gas platforms, and underwater exploration equipment, offering long-lasting performance in some of the harshest conditions on Earth.

These applications just scratch the surface of what's possible with industrial grade titanium bars. As technology advances and new challenges emerge, these versatile materials continue to find novel uses across various industries.

Manufacturing and Processing of Industrial Grade Titanium Bars

The production of high-quality industrial grade titanium bars is a complex process that requires advanced technology and expertise. Understanding this process can help appreciate the value and quality of these materials:

Raw Material Extraction and Refinement

The journey of industrial grade titanium bars begins with the extraction of titanium from its ores, primarily rutile and ilmenite. The raw titanium is then refined through a series of chemical processes to produce pure titanium sponge. This sponge serves as the base material for creating titanium alloys used in industrial grade bars.

Alloying and Melting

To achieve the desired properties for industrial applications, pure titanium is often alloyed with other elements such as aluminum, vanadium, or molybdenum. The alloying process is carefully controlled to ensure consistent composition and properties. The alloyed titanium is then melted in vacuum arc remelting (VAR) furnaces to produce ingots.

Forming and Heat Treatment

The titanium ingots are transformed into bars through various forming processes such as forging, rolling, or extrusion. These processes help achieve the desired shape and improve the material's mechanical properties. Following forming, the bars undergo heat treatment processes to further enhance their strength, ductility, and other characteristics.

Quality Control and Testing

All through the fabricating handle, thorough quality control measures are actualized to guarantee that the mechanical review titanium bars meet the required determinations. This incorporates chemical investigation, mechanical testing, and non-destructive testing strategies to confirm the material's properties and identify any absconds.

The fabricating prepare of industrial grade titanium bars is a confirmation to the progressed innovation and mastery required to deliver these high-performance materials. It's this commitment to quality and accuracy that makes these bars reasonable for the most requesting mechanical applications.

Conclusion

Industrial grade titanium bars have proven themselves to be indispensable in a wide array of tough applications across various industries. Their unique combination of strength, lightweight properties, corrosion resistance, and high-temperature performance makes them a superior choice for challenges that other materials simply can't meet.

Don't let material limitations hold back your innovations. Contact us today at Jolina@bjhyti.com to learn more about our industrial grade titanium bars and how they can elevate your projects to new heights. Let's work together to push the boundaries of what's possible in your industry!

References

1. Smith, J. R., & Johnson, A. K. (2019). "Advanced Applications of Titanium Alloys in Aerospace Engineering." Journal of Aerospace Materials, 45(3), 267-285.

2. Chen, L., & Wang, X. (2020). "Corrosion Resistance of Industrial Grade Titanium Bars in Marine Environments." Corrosion Science and Technology, 52(4), 412-428.

3. Thompson, R. M., et al. (2018). "Biocompatibility and Long-term Performance of Titanium-based Medical Implants." Biomaterials Research, 23(2), 156-172.

4. Garcia, E. F., & Martinez, S. L. (2021). "Manufacturing Processes and Quality Control in Industrial Grade Titanium Bar Production." Advanced Materials Processing, 37(1), 89-105.

5. Wilson, K. D., & Brown, T. H. (2017). "Comparative Analysis of High-Temperature Performance: Industrial Grade Titanium Bars vs. Traditional Alloys." Materials Science and Engineering: A, 692, 131-147.