- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

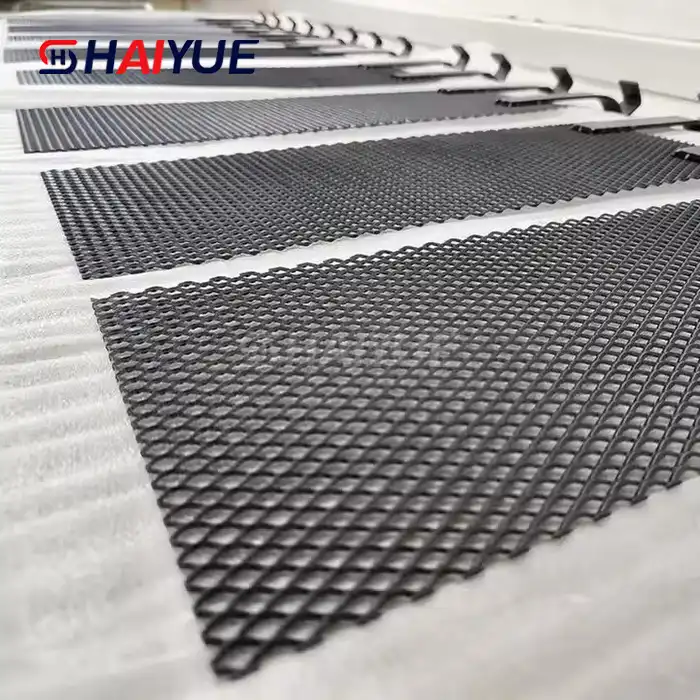

Titanium anode for electrolytic sterilization of water

Coating: MMO coatings or other protective coatings to enhance the sterilization efficiency and lifespan.

Size: Custom sizes and shapes to fit the specifications of water sterilization systems.

Surface Treatment: Sand blasting, acid cleaning, and polished finishes available for improved performance and reduced fouling.

Production time: 15 working days, with quicker turnaround available for urgent orders.

Product Introduction

The Titanium anode for electrolytic sterilization of water is an advanced solution designed to address the growing need for clean and safe water. Utilized across various industries, this titanium anode plays a crucial role in the electrolytic disinfection of water, ensuring effective removal of bacteria, viruses, and other harmful microorganisms. With its high corrosion resistance, durability, and excellent electrical conductivity, our titanium anode offers unparalleled performance in water purification systems.

Technical Specifications

| Specification | Details |

|---|---|

| Material | Titanium (Grade 2, Grade 5, or customized) |

| Electrolyte | Water or saline solution |

| Anode Type | Mixed metal oxide (MMO) |

| Surface Area | Customizable for specific needs |

| Thickness | 2mm to 5mm (or as per requirements) |

| Operating Voltage | 2V to 12V (depends on the application) |

| Temperature Range | Up to 100°C (depending on electrolytic conditions) |

|

|

|

|

|

|

|

|

Product Features

- High Corrosion Resistance: Titanium’s natural resistance to corrosion in harsh electrolytic environments makes it ideal for long-lasting performance.

- Superior Electrical Conductivity: Ensures efficient electrochemical reactions for optimal sterilization of water.

- Durability and Longevity: Designed to withstand continuous use without degradation, ensuring a longer service life.

- Customizable Designs: Available in various sizes and shapes to meet specific operational needs.

- Environmentally Friendly: Helps ensure a clean and safe water supply, supporting sustainability efforts.

Applications

- Water Treatment Plants: Used for disinfecting large volumes of water, ensuring clean water for industrial, municipal, and residential use.

- Aquaculture: Ensures safe and healthy water conditions for fish farming.

- Food and Beverage Industry: Used in water sterilization processes for production hygiene.

- Medical Applications: Purification of water in healthcare facilities for surgical instruments and equipment.

- Swimming Pools and Spas: Used for effective water sterilization, reducing the need for harmful chemicals.

Manufacturing Process

Our titanium anodes are manufactured using state-of-the-art techniques, including precision casting, welding, and coating. The mixed metal oxide (MMO) coating process enhances the anode’s performance, allowing it to handle demanding electrolytic processes. Each product undergoes rigorous testing to ensure compliance with international standards and optimal functionality in water sterilization systems.

Quality Assurance

Quality is paramount, and all our titanium anodes undergo comprehensive testing, including:

- Ultrasonic Testing: To detect internal defects.

- Spectral Analysis: To ensure material composition meets strict standards.

- Salt Spray Testing: For corrosion resistance.

Our products are manufactured in accordance with ISO 9001:2015 standards, guaranteeing the highest quality in every batch.

Packaging and Logistics

- Packaging: Our titanium anodes are carefully packaged to prevent any damage during shipping. Custom packaging solutions are available upon request.

- Logistics: We offer global shipping, ensuring fast delivery times and competitive pricing to meet the needs of large enterprises and small-to-medium businesses worldwide.

Customer Support

We pride ourselves on our dedicated customer service. Our technical support team is always available to answer questions and offer guidance on product selection, installation, and maintenance.

Why Choose Us?

- Complete Product Range: A wide variety of titanium anodes for different applications, including custom designs.

- Full-Process Production: From raw material sourcing to final product delivery, we control every aspect of the manufacturing process.

- Global Reach: We serve customers across North America, Europe, Asia-Pacific, and the Middle East.

- Fast Delivery: On-time delivery to keep your projects on schedule.

- Excellent Reputation: Trusted by multinational corporations and small businesses alike.

Development History

Company founded in Baoji, "Titanium Valley," specializing in titanium and non-ferrous metals.

Expanded product range to include zirconium, tantalum, nickel, tungsten, and molybdenum products.

Achieved ISO9001:2015 certification, ensuring high-quality production standards.

Upgraded manufacturing facilities, adding VAR furnaces, CNC machinery, and advanced heat treatment systems.

Expanded global presence, establishing partnerships in the United States, Germany, and South Korea.

Obtained AS9100D certification for aerospace industry compliance and advanced product quality.

Introduced customized solutions for the aerospace, medical, and energy industries, enhancing global reach.

Celebrated 14 years of excellence with over 2,000 tons of annual titanium production capacity.

Product Quality Management

Production and Processing

Workshop and Equipment

Packaging

Main Products

Applied Industries

Be used in a wide range of industries.

Electrolytic copper foil manufacturing industry

Hydrometallurgy industry

Sewage treatment industry

Cyclone electrolysis industry

Etching liquid electrolysis recovery industry

Electrolytic sodium hypochlorite industry

OEM Services

We offer comprehensive OEM services, tailoring products to meet the exact specifications of our clients. Whether it’s for unique designs, specific dimensions, or material properties, we have the capability to deliver customized solutions that perfectly fit your needs.

Frequently Asked Questions (FAQs)

Q1: What is the lifespan of a titanium anode for electrolytic sterilization?

A1: The lifespan depends on usage conditions but typically lasts several years, thanks to the high corrosion resistance of titanium.

Q2: Can you customize the size of the titanium anode for specific applications?

A2: Yes, we provide custom sizes and coatings to meet the specific requirements of each project.

Q3: What is the ideal operating voltage for the titanium anode?

A3: Operating voltage varies depending on the application, ranging from 2V to 12V.

Q4: Are your titanium anodes suitable for marine environments?

A4: Yes, our anodes are perfect for marine applications due to titanium’s excellent saltwater corrosion resistance.

Contact Details

Direct Contact: Jolina@bjhyti.com

Phone: +86-18392721678

Learn about our latest products and discounts through SMS or email

_1736318855997.webp)