- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

1/8th inch titanium plate vs bullet

2.Lightweight design, perfect for aerospace and marine industries.

3.Superior surface finish for reliable industrial applications.

4.Excellent weldability and formability for custom projects.

5.Precision thickness control ensures consistent performance.

1/8 Inch Titanium Plate vs Bullet: A Comprehensive Comparison

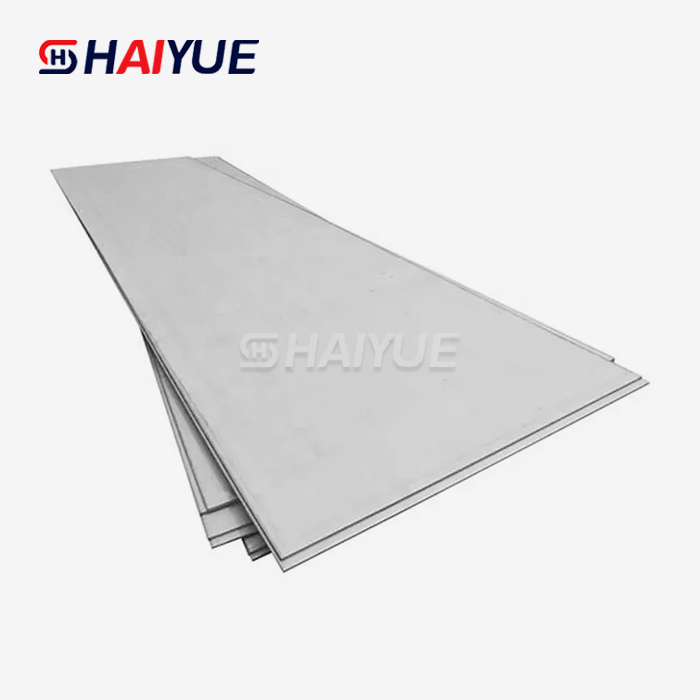

Product Introduction

When it comes to advanced materials for critical applications, few metals are as versatile and sought-after as titanium. One of its most popular forms is the 1/8 inch titanium plate, widely used across industries due to its outstanding properties. In particular, its strength-to-weight ratio, corrosion resistance, and durability make it a top choice in aerospace, medical devices, and military applications.

But how does a 1/8 inch titanium plate stack up against a bullet? This is an important question when considering titanium's role in defense, safety, and other high-performance sectors. Whether you're looking at titanium for bulletproof applications or understanding its performance against projectiles, it's essential to dive deep into the comparison of 1/8 inch titanium plate vs bullet.

This guide will explore the differences, technical specifications, and applications of 1/8 inch titanium plate as compared to bullet resistance.

Technical Specifications

The 1/8 inch titanium plate is a versatile material used across various industries, known for its exceptional strength, lightweight properties, and resistance to corrosion. Below are detailed technical specifications of the 1/8 inch titanium plate and its resistance to bullets.

| Material | 1/8 Inch Titanium Plate | Bullet |

|---|---|---|

| Material Type | Commercially pure titanium or titanium alloy | Typically lead, copper-jacketed, or steel-core |

| Standard Grades | ASTM B265, AMS 4911, AMS 4928, ASTM F67 | Varies by type (e.g., NATO standards) |

| Thickness | 1/8 inch (3.175 mm) | 5.56mm to 7.62mm (varies with bullet type) |

| Density | ~4.51 g/cm³ | ~7.8 g/cm³ (lead) |

| Tensile Strength | ~880 MPa (for Grade 2 titanium) | ~400–900 MPa (varies by bullet material) |

| Hardness (Vickers) | 160-230 HV | 35-90 HV depending on bullet type and velocity |

| Corrosion Resistance | Excellent (particularly in marine and chemical environments) | None (bullets are highly reactive and corrode quickly) |

| Impact Resistance | High (designed for structural applications) | High, but designed to penetrate or deform materials |

| Melting Point | ~1,668°C | ~327°C (Lead), varies with bullet material |

| Thermal Conductivity | 21.9 W/m·K | ~35 W/m·K (for lead bullets) |

Production Standards (1/8 Inch Titanium Plate)

The 1/8 inch titanium plate is typically manufactured according to rigorous international standards to ensure its quality and performance. Below are the relevant production grades and standards for the 1/8 inch titanium plate:

| Country | Standard | Grade/Material Type |

|---|---|---|

| USA | ASTM B265, ASTM F67, AMS 4911, AMS 4928 | CP Ti (Commercial Pure Titanium), Ti-6Al-4V |

| Russia | GOST 19807-91, GOST 19809-91 | Ti-6Al-4V, Ti-1, Ti-3, Ti-4 |

| Japan | JIS H 4600, JIS H 4650 | JIS Grade 2, JIS Grade 5 |

|

|

|

|

|

|

|

|

Product Features (Key Features)

- High Strength-to-Weight Ratio: Titanium is known for being significantly stronger than steel while weighing much less, making it ideal for aerospace and defense applications.

- Corrosion Resistance: Titanium is highly resistant to corrosion, even in harsh environments like saltwater or acidic conditions.

- Lightweight: At 4.51 g/cm³, titanium is much lighter than other metals like steel, making it perfect for applications where weight is a concern.

- Heat Resistance: Titanium can withstand high temperatures, making it suitable for aerospace applications where heat from friction can be extreme.

- Durability: Titanium plates are durable and can withstand significant impact, making them ideal for armor applications and other protective uses.

Applications

1/8 inch titanium plates are used in a wide range of industries, from aerospace to medical applications. Here are some of the most common applications:

- Aerospace: Components like structural parts, engine parts, and fasteners.

- Medical Devices: Surgical instruments, implants, and prosthetics.

- Chemical Processing: Equipment that must withstand aggressive chemicals and high temperatures.

- Military and Defense: Armor and other defense-related applications.

- Marine Engineering: Saltwater-resistant components for shipbuilding.

- Automotive: High-performance vehicles and racing.

Manufacturing Process

The manufacturing process of 1/8 inch titanium plate involves several critical steps to ensure high-quality production. Here’s an overview:

- Extraction: Titanium is extracted from titanium ore, often using the Kroll Process, where titanium tetrachloride is reduced to titanium sponge.

- Forming: The titanium sponge is melted and formed into plates through processes like casting or rolling.

- Heat Treatment: To increase strength and durability, titanium plates are often heat-treated to improve their mechanical properties.

- Finishing: After rolling and heat treatment, the titanium plates are polished, cut, and finished to meet specific customer requirements.

Quality Assurance

Baoji Haiyue New Metal Materials Co., Ltd. takes quality seriously. The 1/8 inch titanium plate undergoes stringent quality checks throughout the production process. The company is certified with ISO9001:2015 and AS9100D, and all products undergo testing using advanced technologies such as ultrasonic and eddy current testing, as well as spectral analysis.

Packaging and Logistics

To ensure safe delivery, 1/8 inch titanium plates are carefully packaged in durable wooden crates or pallets, with protective padding to prevent damage during transportation. Baoji Haiyue offers global logistics services, ensuring timely delivery to customers worldwide.

Customer Support

We pride ourselves on providing excellent customer support. Our team of engineers and technicians is always available to assist you with any queries, whether it’s about material properties, specifications, or custom requirements.

Why Choose Us

- Complete Product Range: We offer a comprehensive range of titanium products, including custom solutions.

- Global Reach: Our products are distributed to over 20 countries worldwide.

- Expertise: With a dedicated team of over 100 engineers, we offer tailored solutions to meet your exact needs.

- Quality Assurance: Our products meet the highest international standards and undergo rigorous quality control.

- Fast Delivery: We ensure quick delivery, even for custom orders.

- Customer Service: Our team is always available to offer after-sales support, including technical consultations.

Development History

Company founded in Baoji, "Titanium Valley," specializing in titanium and non-ferrous metals.

Expanded product range to include zirconium, tantalum, nickel, tungsten, and molybdenum products.

Achieved ISO9001:2015 certification, ensuring high-quality production standards.

Upgraded manufacturing facilities, adding VAR furnaces, CNC machinery, and advanced heat treatment systems.

Expanded global presence, establishing partnerships in the United States, Germany, and South Korea.

Obtained AS9100D certification for aerospace industry compliance and advanced product quality.

Introduced customized solutions for the aerospace, medical, and energy industries, enhancing global reach.

Celebrated 14 years of excellence with over 2,000 tons of annual titanium production capacity.

Product Quality Management

Production and Processing

Workshop and Equipment

Packaging

Main Products

Applied Industries

Be used in a wide range of industries.

Electrolytic copper foil manufacturing industry

Hydrometallurgy industry

Sewage treatment industry

Cyclone electrolysis industry

Etching liquid electrolysis recovery industry

Electrolytic sodium hypochlorite industry

OEM Services

We offer full OEM services for customers who require custom specifications. Whether you need custom sizes, shapes, or mechanical properties, our engineers can work with you to design the perfect product for your application.

Frequently Asked Questions (FAQs)

Q: What is the strength of a 1/8 inch titanium plate compared to bulletproof materials?

A: Titanium is highly resistant to impact and can stop many types of bullets when used in the right thickness. However, for certain high-velocity bullets, additional materials may be required.

Q: Can titanium plates be used for ballistic armor?

A: Yes, titanium plates are often used in ballistic armor, as they provide an excellent combination of strength and lightweight properties.

Q: How does 1/8 inch titanium plate compare to steel in terms of weight?

A: Titanium is significantly lighter than steel, which makes it a better choice for applications where reducing weight is crucial.

Contact Details

For more information or to request a quote, feel free to contact us:

- Email:Jolina@bjhyti.com

- Phone: +86-18392721678

Learn about our latest products and discounts through SMS or email

_1740471776993.webp)

_1739500727882.webp)