- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Raised Face Titanium flange

2.Lightweight and strong for efficient piping connections.

3.Precision-machined for excellent sealing performance.

4.High-temperature tolerance for industrial applications.

5.Custom sizes and standards to fit specific requirements.

Raised Face Titanium Flange: Engineered Excellence for Precision Applications

Product Introduction

Elevate your industrial operations with our premium Raised Face Titanium Flange—a versatile solution engineered for strength, durability, and seamless integration across demanding applications. Crafted with Baoji Haiyue’s cutting-edge expertise, our titanium flanges deliver exceptional performance while adhering to stringent global quality standards.

As a proud product of Baoji, the “Titanium Valley” of China, our Raised Face Titanium Flanges embody the perfect balance of innovation, quality, and reliability. Whether you're in aerospace, medical, marine, or industrial manufacturing, these flanges ensure superior functionality and longevity.

Technical Specifications

Our Raised Face Titanium Flange is meticulously crafted to meet the diverse needs of industries worldwide. Below are detailed specifications:

Material Composition and Grades

| Standard | Grade | Composition |

|---|---|---|

| ASTM | Grade 2, Grade 5 | CP Titanium, Ti-6Al-4V |

| JIS | 2, 16 | Pure Titanium |

| GOST (Russia) | VT1-0, BT6 | Titanium Alloys |

Dimensional Specifications

| Parameter | Range |

|---|---|

| Diameter | 10 mm – 1200 mm |

| Thickness | 5 mm – 50 mm |

| Pressure Class | ANSI 150 – 2500 lbs |

Mechanical Properties

| Property | Grade 2 | Grade 5 |

|---|---|---|

| Tensile Strength | ≥ 345 MPa | ≥ 895 MPa |

| Yield Strength | ≥ 275 MPa | ≥ 828 MPa |

| Elongation | ≥ 20% | ≥ 10% |

|

|

|

|

|

|

|

|

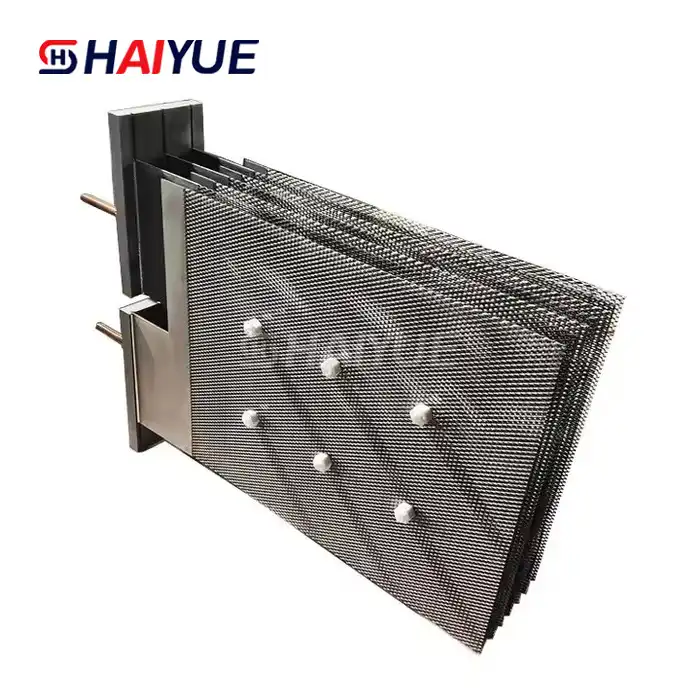

Product Features

- Corrosion Resistance: Unmatched durability in harsh environments, including saltwater and chemical exposure.

- High Strength-to-Weight Ratio: Lightweight yet strong, ideal for applications demanding structural integrity.

- Thermal Stability: Performs reliably under extreme temperatures.

- Customizable Design: Available in varied dimensions and configurations to meet specific project requirements.

Applications

Our Raised Face Titanium Flanges are indispensable across industries:

- Aerospace: Precision-engineered for aircraft engine components and structural assemblies.

- Medical Devices: Perfect for biocompatible implants and surgical instruments.

- Chemical Processing: Reliable in reactors, storage tanks, and piping systems.

- Marine Engineering: Resists saltwater corrosion for offshore platforms and shipbuilding.

- Energy Sector: Suitable for nuclear reactors, wind turbines, and solar installations.

Manufacturing Process

Our state-of-the-art facilities ensure exceptional quality:

- Material Sourcing: Premium titanium sourced from certified suppliers.

- Precision Machining: CNC-machined to achieve exact dimensions.

- Heat Treatment: Enhances mechanical properties and stress relief.

- Surface Finishing: Advanced plasma arc welding and polishing for optimal performance.

Quality Assurance

Quality is our promise. Every product undergoes:

- Material Testing: Spectral analysis to confirm composition.

- Non-Destructive Testing: Ultrasonic and eddy current inspections.

- Dimensional Verification: Ensuring compliance with international standards.

Certifications: ISO9001:2015, AS9100D, GJB9001C:2007.

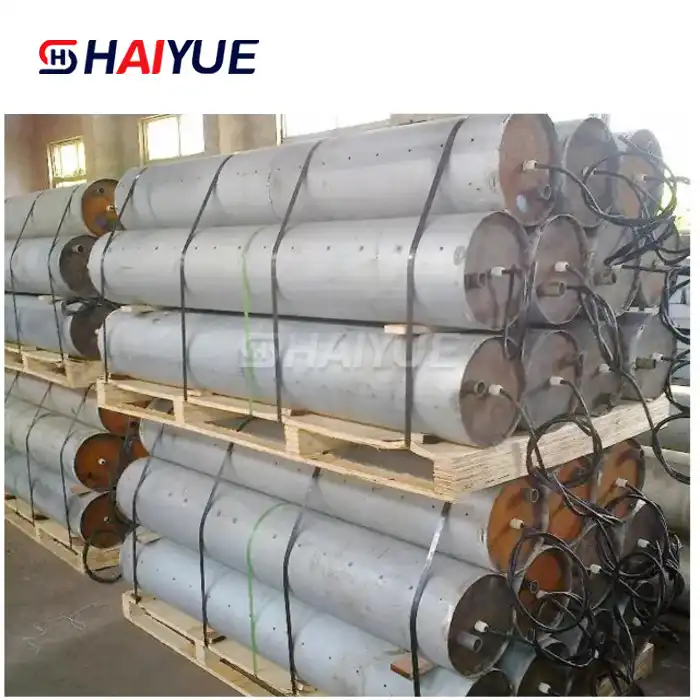

Packaging and Logistics

To protect your investment:

- Packaging: Robust, eco-friendly crates with protective linings.

- Shipping: Fast, reliable logistics for global destinations.

Customer Support

Our team is here to assist:

- Technical Consultations: Expert guidance tailored to your application.

- After-Sales Support: Prompt response for any product-related inquiries.

Why Choose Us?

- Complete Product Range: From raw materials to finished components.

- Global Reach: Supplying to over 20 countries.

- Customization: Tailored solutions to meet unique needs.

- Fast Delivery: Efficient production and shipping timelines.

- Sustainability: Eco-friendly practices for a greener future.

Development History

Company founded in Baoji, "Titanium Valley," specializing in titanium and non-ferrous metals.

Expanded product range to include zirconium, tantalum, nickel, tungsten, and molybdenum products.

Achieved ISO9001:2015 certification, ensuring high-quality production standards.

Upgraded manufacturing facilities, adding VAR furnaces, CNC machinery, and advanced heat treatment systems.

Expanded global presence, establishing partnerships in the United States, Germany, and South Korea.

Obtained AS9100D certification for aerospace industry compliance and advanced product quality.

Introduced customized solutions for the aerospace, medical, and energy industries, enhancing global reach.

Celebrated 14 years of excellence with over 2,000 tons of annual titanium production capacity.

Product Quality Management

Production and Processing

Workshop and Equipment

Packaging

Main Products

Applied Industries

Be used in a wide range of industries.

Electrolytic copper foil manufacturing industry

Hydrometallurgy industry

Sewage treatment industry

Cyclone electrolysis industry

Etching liquid electrolysis recovery industry

Electrolytic sodium hypochlorite industry

OEM Services

We partner with OEMs to deliver custom flanges designed for specific applications. Leverage our technical expertise and advanced manufacturing capabilities for your projects.

Frequently Asked Questions (FAQs)

1. What are Raised Face Titanium Flanges used for?

They are primarily used in pipelines to provide a seal with gaskets, ensuring leak-proof connections.

2. Can I request custom dimensions?

Absolutely! Our flanges can be customized to your exact specifications.

3. What certifications do your products have?

Our products meet ISO9001:2015, AS9100D, and GJB9001C:2007 standards.

Contact Details

📧 Email:Jolina@bjhyti.com

📞 Phone: +86-18392721678

📢 Get in touch for a quote today and experience premium quality Raised Face Titanium Flanges tailored to your needs!

Learn about our latest products and discounts through SMS or email

(1)_1750228612822.webp)