- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Aerospace Titanium Alloy Plate

2.Lightweight design, perfect for aerospace and marine industries.

3.Superior surface finish for reliable industrial applications.

4.Excellent weldability and formability for custom projects.

5.Precision thickness control ensures consistent performance.

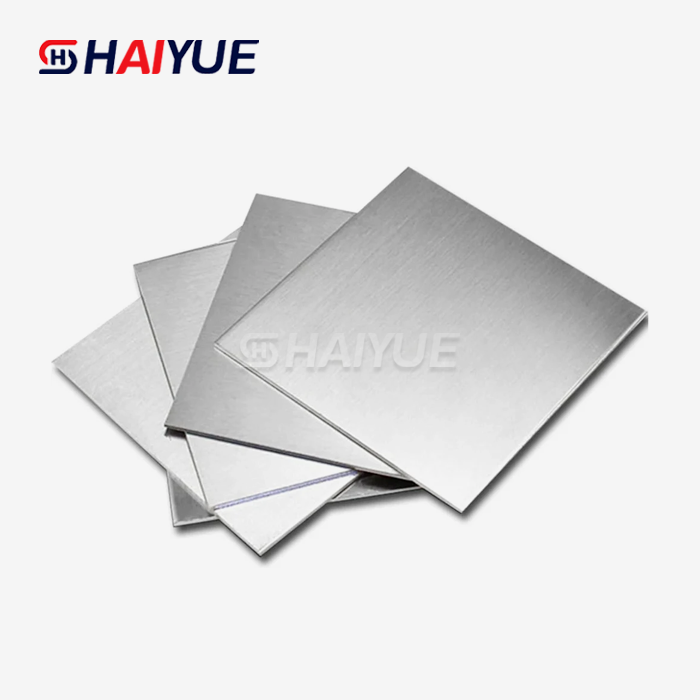

Aerospace Titanium Alloy Plate: High-Performance Materials for Precision Applications

Product Introduction

Aerospace Titanium Alloy Plate is a premium material specifically designed for critical applications in industries such as aerospace, medical, chemical processing, energy, and marine engineering. Known for its exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility, titanium alloy is the material of choice for high-performance components in demanding environments. Baoji Haiyue New Metal Materials Co., Ltd. offers aerospace-grade titanium alloy plates that meet the most stringent international standards, ensuring superior quality and reliability for our global clientele.

Technical Specifications

| Specification | Grade | Chemical Composition | Properties | Standard |

|---|---|---|---|---|

| Aerospace Grade | Ti-6Al-4V | 90% Titanium, 6% Aluminum, 4% Vanadium | High strength, corrosion resistance, lightweight | ASTM B265, AMS 4911, AS9100D |

| Ultra High Strength | Ti-6Al-2Sn-4Zr-6Mo | 89.5% Titanium, 6% Aluminum, 2% Tin, 4% Zirconium, 6% Molybdenum | Increased fatigue resistance, high temperature strength | AMS 4931, AMS 4911 |

| Low-Alloy Titanium | Ti-3Al-2.5V | 94.5% Titanium, 3% Aluminum, 2.5% Vanadium | Excellent weldability, light, and strong | AMS 4915 |

| Russian Standard | VT6 | 90% Titanium, 6% Aluminum, 4% Vanadium | High strength-to-weight ratio, oxidation resistance | GOST 19807-2014 |

| Japanese Standard | Ti-6Al-4V ELI | 90% Titanium, 6% Aluminum, 4% Vanadium | Exceptional fatigue resistance, excellent formability | JIS H 4654 |

|

|

|

|

|

|

|

|

Product Features (Key Features)

- Exceptional Strength and Lightweight: Aerospace Titanium Alloy Plates offer high strength while being significantly lighter than many other metals, making them ideal for reducing the weight of aircraft, spacecraft, and other transportation systems.

- Corrosion Resistance: These plates are resistant to corrosion in harsh environments, including saltwater and chemical exposure, making them perfect for marine and chemical applications.

- Biocompatibility: Non-toxic and highly biocompatible, making them suitable for medical devices such as implants, surgical tools, and prosthetics.

- High Temperature Resistance: Designed to withstand high temperatures, making them suitable for aerospace applications where extreme conditions are encountered.

- Customizable: Available in various thicknesses and sizes to meet the specific needs of customers in different industries.

Applications

Aerospace Titanium Alloy Plates are utilized in numerous high-performance sectors:

- Aerospace & Aviation: Structural components of aircraft and spacecraft, including fuselages, wings, and turbine blades.

- Medical Devices: Implants, surgical instruments, and medical tools, where corrosion resistance and biocompatibility are critical.

- Chemical Processing: Heat exchangers, reactors, and piping systems resistant to aggressive chemicals and high temperatures.

- Energy Sector: Components for power generation in nuclear reactors, wind turbines, and solar power systems.

- Marine Engineering: Offshore platforms, shipbuilding, and underwater equipment exposed to harsh marine environments.

- Industrial Manufacturing: Components for high-stress machinery, fasteners, and tooling.

Manufacturing Process

At Baoji Haiyue, the production of Aerospace Titanium Alloy Plates follows a strict process to guarantee superior quality:

- Material Selection: Only premium-grade titanium and alloy components are selected to ensure material strength and purity.

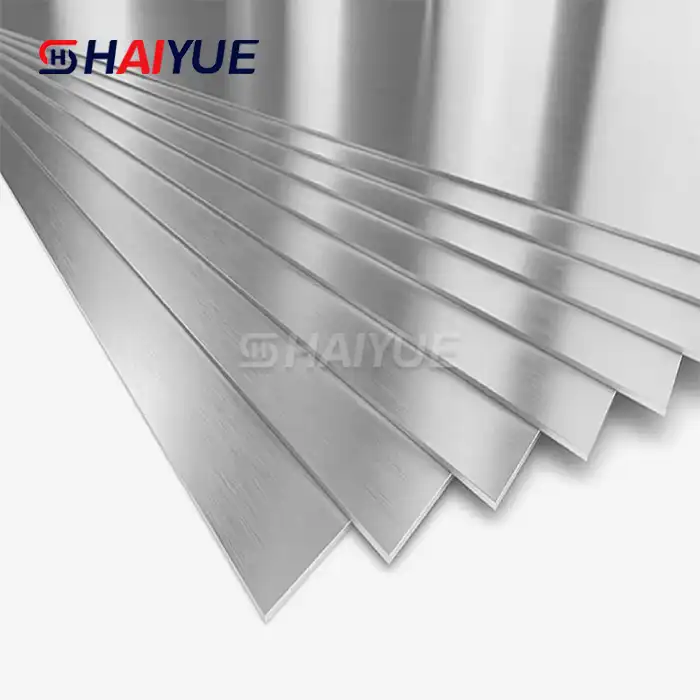

- Hot Working: Plates are hot-rolled to achieve the required thickness and mechanical properties.

- Cold Rolling: After hot working, plates are cold-rolled to enhance surface finish and dimensional accuracy.

- Heat Treatment: Each plate undergoes heat treatment to optimize strength, toughness, and resistance to high temperatures.

- Surface Finishing: Plates are polished and treated for enhanced surface quality and corrosion resistance.

- Cutting and Shaping: Final custom shapes and sizes are cut using advanced CNC machines to meet customer requirements.

Quality Assurance

Quality is at the core of our operations. We conduct rigorous testing at each stage of production to ensure the highest standards are met:

- Material Inspection: Comprehensive chemical and mechanical property analysis using spectroscopy and ultrasonic testing.

- Dimensional Accuracy: Advanced metrology ensures every plate meets the exact specifications.

- Surface Integrity: Eddy current and X-ray inspection detect any hidden cracks or defects.

- Certification: All products meet international standards, including ISO9001:2015, AS9100D, and ASTM certifications.

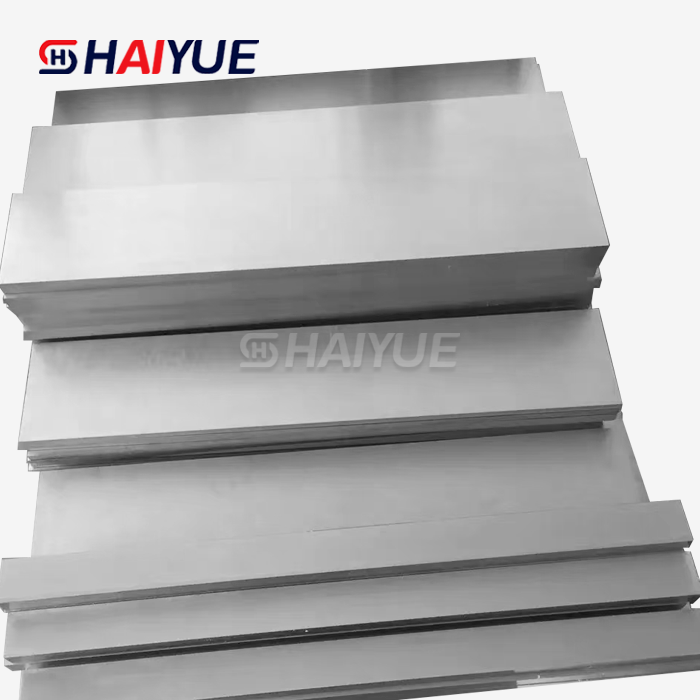

Packaging and Logistics

To ensure safe delivery worldwide, our Aerospace Titanium Alloy Plates are packaged using advanced protective materials that prevent damage during transport. We provide:

- Custom Packaging: Tailored packaging to suit the specific dimensions and shipping requirements.

- Global Shipping: Fast and reliable shipping services to North America, Europe, Asia, and beyond.

- Trackable Logistics: Real-time tracking to ensure timely delivery and complete visibility.

Customer Support

At Baoji Haiyue, customer satisfaction is our priority. Our support team is available to assist you with:

- Product Inquiries: Detailed answers to any questions regarding material properties or applications.

- Technical Assistance: Support with material selection, usage advice, and custom orders.

- Order Tracking: Assistance in tracking your orders from production to delivery.

Why Choose Us

- Complete Product Range: We offer a wide range of titanium and non-ferrous metal products, ensuring one-stop solutions for your needs.

- Full-Process Production: From raw materials to finished products, we control every stage of the manufacturing process for optimal quality.

- Global Reach: Serving clients in over 20 countries, with an established network of distributors and agents worldwide.

- Custom Solutions: Tailored to meet your exact specifications for size, shape, and material properties.

- Fast Delivery: Timely production and shipping ensure your project stays on track.

- Reputation: Trusted by leading companies in aerospace, medical, energy, and industrial sectors.

- After-Sales Service: We offer door-to-door service and prompt support for any issues that arise.

OEM Services

We offer customized solutions for Original Equipment Manufacturers (OEMs) looking for tailored titanium alloy plates. Our team works closely with you to provide materials that meet your exact specifications, ensuring the highest performance for your end products.

Frequently Asked Questions (FAQs)

-

What is the thickness range for Aerospace Titanium Alloy Plates? We offer a variety of thicknesses from 0.5 mm to 100 mm, depending on your requirements.

-

Can I order customized sizes or shapes? Yes, we specialize in custom orders to meet your specific needs.

-

Are your Aerospace Titanium Alloy Plates certified? Yes, all our products meet international standards, including ASTM, AMS, and ISO certifications.

-

What is the lead time for large orders? Typically, large orders are processed within 2-4 weeks, depending on complexity and stock availability.

-

Do you offer samples? Yes, we can provide samples for evaluation before placing a bulk order.

Contact Details

For more information, quotes, or to place an order, please contact us:

- Email:Jolina@bjhyti.com

- Phone: +86-18392721678

Development History

Company founded in Baoji, "Titanium Valley," specializing in titanium and non-ferrous metals.

Expanded product range to include zirconium, tantalum, nickel, tungsten, and molybdenum products.

Achieved ISO9001:2015 certification, ensuring high-quality production standards.

Upgraded manufacturing facilities, adding VAR furnaces, CNC machinery, and advanced heat treatment systems.

Expanded global presence, establishing partnerships in the United States, Germany, and South Korea.

Obtained AS9100D certification for aerospace industry compliance and advanced product quality.

Introduced customized solutions for the aerospace, medical, and energy industries, enhancing global reach.

Celebrated 14 years of excellence with over 2,000 tons of annual titanium production capacity.

Product Quality Management

Production and Processing

Workshop and Equipment

Packaging

Main Products

Applied Industries

Be used in a wide range of industries.

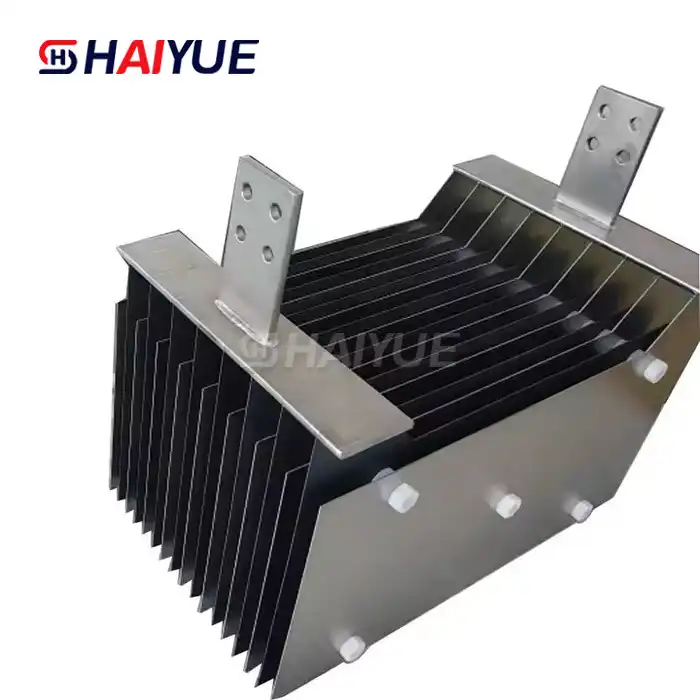

Electrolytic copper foil manufacturing industry

Hydrometallurgy industry

Sewage treatment industry

Cyclone electrolysis industry

Etching liquid electrolysis recovery industry

Electrolytic sodium hypochlorite industry

Learn about our latest products and discounts through SMS or email

_1740366557275.webp)

(1)_1740624849034.webp)