- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why Titanium M12x15 Lug Nuts Are the Smart Choice for High Performance and Daily Driving Vehicles

Titanium lug nuts are increasingly favored by automotive professionals and enthusiasts for their outstanding combination of lightweight structure high tensile strength and corrosion resistance This 20 piece set of M12x15 closed end lug nuts provides a practical and performance focused solution for drivers seeking long term reliability and enhanced vehicle dynamics

|

|

|

|

|

Aerospace Grade Titanium for Structural Integrity

This lug nut set is made from Grade 5 titanium alloy also known as Ti 6Al 4V a material commonly used in aerospace components due to its remarkable mechanical properties and environmental resistance

The alloy offers a typical tensile strength of approximately 950 megapascals and performs consistently under high heat and load conditions It also resists corrosion from road salt moisture and chemicals making it ideal for use in both performance vehicles and everyday cars

Grade 5 titanium is widely recognized for its fatigue resistance low density and nonmagnetic nature which contributes to safe and efficient performance in demanding automotive environments

Uncoated Natural Metal Finish for Authentic Appearance

These lug nuts are supplied in their natural raw titanium finish without any surface coating or coloring This allows the pure metallic texture to show through while eliminating risks of fading flaking or discoloration that can occur with painted or anodized products

The oxide layer that naturally forms on titanium further enhances its corrosion resistance without the need for artificial treatment This finish is highly durable and retains its clean appearance even after long term use

By maintaining an uncoated surface users can also ensure accurate torque values during installation as no soft layer interferes with the thread engagement

Lightweight Advantage for Performance and Efficiency

Titanium is approximately 40 percent lighter than steel which makes these lug nuts a valuable upgrade for reducing unsprung weight on a vehicle Lower unsprung weight improves suspension response steering feedback and braking performance

This weight reduction also translates to reduced rotational inertia at the wheel hub contributing to sharper handling better throttle response and lower fuel consumption in certain applications

The benefits of lightweight fasteners are particularly noticeable in high speed cornering and track use where precision control is essential but they also enhance the overall smoothness of daily driving

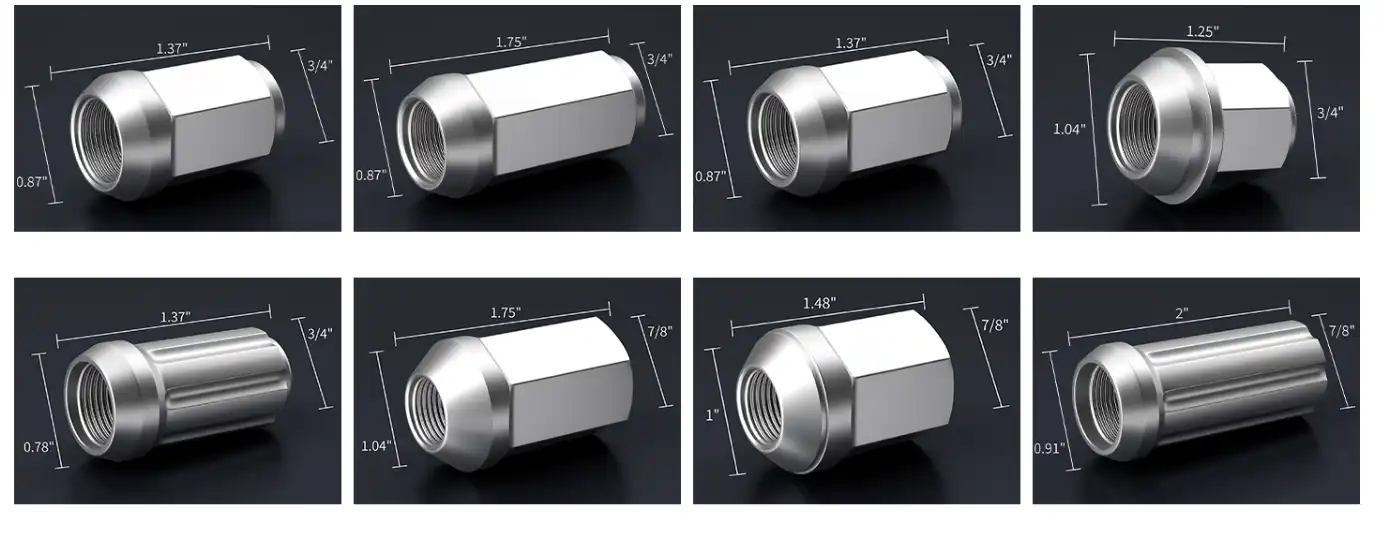

Technical Specifications

Thread pitch 12mm x 15

Hex size 19mm or three quarter inch

Length 35mm

Width 22mm

Seat type 60 degree conical

Design one piece construction with closed end

These specifications ensure compatibility with most OE wheels and aftermarket rims that use conical seats The closed end design adds structural strength while preventing dirt or water ingress from the exposed stud end

Each lug nut is CNC machined to high precision to ensure uniform thread engagement and optimal torque retention during use

Compatibility with a Wide Range of Vehicles

This titanium lug nut set is compatible with vehicles that use M12x15 thread pitch and 60 degree conical seat wheels including sedans crossovers and compact SUVs

Fitment examples include

Honda Civic from 2006 to 2024

Honda Accord from 2003 to 2024

Honda CR V from 1997 to 2024

Honda HR V from 2016 to 2024

Ford Escape from 2001 to 2023

Ford Focus from 2000 to 2019

Ford Fusion from 2006 to 2020

Toyota Corolla Camry and Prius

Hyundai Elantra Sonata and Kona

Users are advised to verify thread pitch seat type and wheel specifications before installation to ensure correct fitment

Recommended Installation Procedure

Use only manual tools such as hand wrenches or calibrated torque wrenches to install and remove these lug nuts Avoid the use of impact tools which may damage the titanium threads or distort the nut body

Clean the wheel studs thoroughly before installation to remove any contaminants or corrosion that may affect torque consistency

Apply a small amount of high temperature anti seize compound to the threads before installation to prevent galling and ensure smooth removal in the future

Tighten the lug nuts in a crisscross star pattern to distribute clamping force evenly Follow manufacturer recommended torque values generally between 85 and 95 foot pounds for M12 thread applications

Retorque the lug nuts after driving approximately 100 kilometers to verify proper seating and torque retention

Long Term Maintenance and Storage

Thanks to the natural corrosion resistance of titanium these lug nuts require very little maintenance For optimal longevity consider the following care tips

Visually inspect periodically for wear or damage especially after track use or frequent tire changes

Clean with mild soap and a soft cloth to remove brake dust and debris

Avoid using acidic or abrasive cleaners that could dull the surface

Store unused lug nuts in a clean dry environment to prevent physical damage

With basic care these titanium lug nuts can maintain their structural and aesthetic qualities for many years

Packaging and Customization Availability

Each set includes twenty titanium lug nuts arranged in a foam padded protective box to prevent scratching or surface damage during shipping and storage

For workshops resellers and performance part suppliers customization services are available including

Laser marking for brand identification

Alternative thread pitches such as M12x15 M14x15 or 12 inch 20 UNF

Anodized color finishes for racing and aesthetic applications

Bulk packaging for commercial distribution

These options support OEM partnerships and aftermarket tuning programs for both street and motorsport applications

Comparative Benefits of Titanium Lug Nuts

Compared to conventional fasteners titanium offers a superior combination of performance and longevity

Steel lug nuts are strong but heavy and prone to rust over time

Aluminum lug nuts are light but vulnerable to deformation and cracking

Titanium lug nuts deliver both low weight and high strength without corrosion

These qualities make titanium fasteners an ideal upgrade for users who prioritize precision performance and durability over low initial cost

Conclusion

This 20 piece set of M12x15 titanium closed end lug nuts delivers outstanding performance advantages for drivers who demand more from their vehicles By utilizing aerospace grade materials precise machining and weight saving design these lug nuts provide improved driving dynamics superior corrosion resistance and long service life across a wide range of vehicles

They are equally suitable for track day builds daily drivers or aftermarket wheel upgrades making them a versatile and highly effective solution for modern automotive applications

References

ClubWRX Forum Subaru Wheels and Suspension Technical Topics

HondaTech Community Civic and Accord Fitment Guides

Ford Focus Fanatics Lug Nut Compatibility Threads

RX7Club Mazda Rotary Vehicle Hardware Discussions

NASIOC North American Subaru Impreza Owners Club Tech Archive

Zilvia Forum Nissan S Chassis Drivetrain Fitment

Engineering Toolbox Material Comparison Tables

Motorsport Tech Wheel Fastener Safety Guidelines

Titanium Engineers Technical Resource Center

TITANIUM TODAY Automotive Application Reports

Wheels and Tires Magazine Lightweight Fastener Reviews

Learn about our latest products and discounts through SMS or email

_1737008281814.webp)

(1)_1737431848933.webp)