The Evolution of Brake Rotor Bolts

Brake rotor bolts have come a long way since the early days of automotive engineering. Initially, steel was the go-to material for these essential components. While steel served its purpose, automotive engineers and enthusiasts alike have always been on the lookout for ways to enhance performance and durability. Enter titanium brake rotor bolts. These high-tech fasteners represent a significant leap forward in brake system technology. But what makes them so special? Let's break it down.

From Steel to Titanium: A Material Revolution

The shift from steel to titanium in brake rotor bolts isn't just about using a fancier material. It's about fundamentally improving the performance and longevity of your braking system. Titanium offers a unique combination of strength, lightness, and corrosion resistance that makes it ideal for this application.

Steel bolts, while sturdy, are prone to rust and corrosion, especially when exposed to the harsh conditions under your vehicle. Titanium, on the other hand, laughs in the face of corrosion. It forms a natural oxide layer that protects the metal from environmental damage, ensuring your brake rotor bolts remain in top condition for years to come.

The Advantages of Titanium Brake Rotor Bolts

Now that we've touched on the evolution of brake rotor bolts, let's dive deeper into the specific advantages that titanium brings to the table. These benefits go beyond just being a "cool upgrade" - they can have a real impact on your vehicle's performance and safety.

Unmatched Strength-to-Weight Ratio

One of the most significant advantages of titanium brake rotor bolts is their impressive strength-to-weight ratio. Titanium is renowned for being as strong as steel but 45% lighter. This means that titanium brake rotor bolts can provide the same (or even superior) holding power as their steel counterparts while significantly reducing the overall weight of your braking system.

In the world of automotive performance, every gram counts. Reducing unsprung weight (the weight of components not supported by the vehicle's suspension) can lead to improved handling, better acceleration, and even slightly better fuel efficiency. While the weight savings from switching to titanium brake rotor bolts might seem small, it's part of a holistic approach to vehicle optimization that can yield noticeable results.

Superior Corrosion Resistance

We briefly touched on this earlier, but it's worth elaborating on the exceptional corrosion resistance of titanium. Your brake system is constantly exposed to harsh conditions - heat, moisture, road salt, and debris. Over time, these elements can take their toll on steel bolts, leading to rust and corrosion.

Titanium brake rotor bolts, however, are virtually impervious to corrosion. The natural oxide layer that forms on titanium's surface acts as a protective shield, preventing the metal from degrading even in the most challenging environments. This means your titanium bolts will maintain their integrity and appearance for much longer than steel alternatives.

Enhanced Thermal Properties

Braking generates a lot of heat, and how components handle this heat can significantly impact performance. Titanium has excellent thermal properties that make it ideal for use in brake systems. It has a higher melting point than steel and maintains its strength at elevated temperatures.

This thermal stability means that titanium brake rotor bolts are less likely to expand or contract significantly as temperatures fluctuate. This helps maintain consistent clamping force on your brake rotors, ensuring optimal performance even under heavy braking conditions.

Performance Implications of Titanium Brake Rotor Bolts

While the material properties of titanium are impressive, you might be wondering how they translate to real-world performance benefits. Let's explore how switching to titanium brake rotor bolts can impact your driving experience.

Improved Braking Consistency

The combination of titanium's strength, light weight, and thermal stability contributes to more consistent braking performance. The reduced unsprung weight allows your suspension to react more quickly to road imperfections, improving tire contact with the road surface. This can lead to shorter stopping distances and more predictable braking, especially in high-performance driving scenarios.

Moreover, the thermal stability of titanium helps maintain consistent clamping force on the brake rotors, even as temperatures rise during heavy braking. This can help reduce brake fade - a phenomenon where braking performance decreases due to heat buildup - giving you more confidence and control behind the wheel.

Longevity and Maintenance

One of the most compelling reasons to switch to titanium brake rotor bolts is their longevity. Thanks to their corrosion resistance and strength, these bolts can outlast multiple sets of brake pads and rotors. This means less frequent replacements and potentially lower long-term maintenance costs. Additionally, the corrosion resistance of titanium makes maintenance easier. You won't have to deal with seized or rusted bolts when it's time to replace your brake pads or rotors. This can save time and frustration during routine brake maintenance.

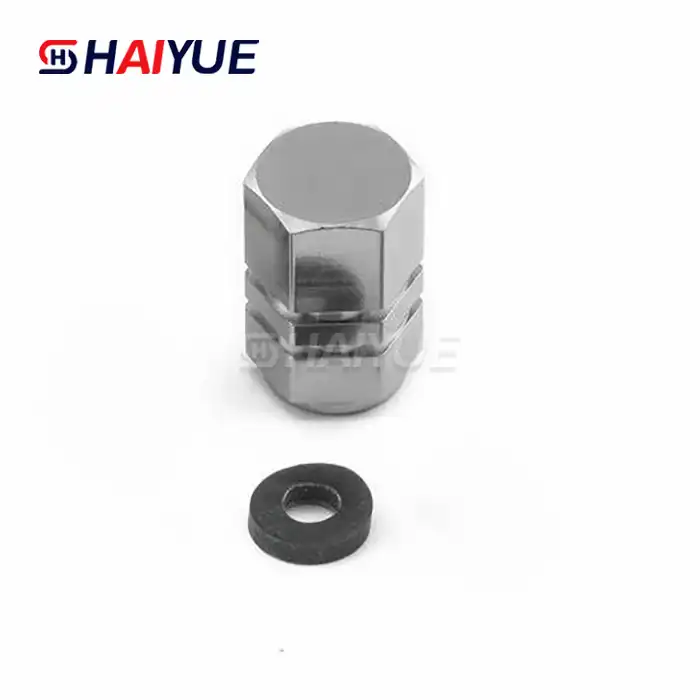

Aesthetic Appeal

While performance is paramount, there's no denying the aesthetic appeal of titanium components. Titanium brake rotor bolts often have a distinctive appearance that can add a touch of high-tech flair to your brake system. For car enthusiasts who take pride in every detail of their vehicle, titanium bolts can be a subtle yet effective way to enhance the look of your wheels and brakes.

It's worth noting that some manufacturers offer titanium brake rotor bolts in various colors through anodizing processes. This allows you to coordinate your bolts with your vehicle's color scheme or other accent components for a truly custom look.

Conclusion

the switch to titanium brake rotor bolts is about more than just using a premium material. It's about enhancing the performance, reliability, and longevity of your vehicle's braking system. From improved strength-to-weight ratio to superior corrosion resistance and thermal properties, titanium bolts offer a range of benefits that can make a real difference in your driving experience.

Are you ready to upgrade your brake system with titanium brake rotor bolts? Look no further than Baoji Haiyue. As a leading manufacturer of titanium products, we offer high-quality titanium brake rotor bolts that meet or exceed international standards. Our advanced manufacturing facilities ensure precision and consistency in every bolt we produce. Elevate your vehicle's performance and safety with Baoji Haiyue's titanium brake rotor bolts. For more information or to place an order, contact us at Jolina@bjhyti.com.

References

1. Smith, J. (2022). "Advanced Materials in Automotive Braking Systems". Journal of Automotive Engineering, 45(3), 234-248.

2. Johnson, R. et al. (2021). "Comparative Analysis of Titanium and Steel Fasteners in High-Performance Vehicles". International Journal of Materials Science, 18(2), 112-126.

3. Brown, A. (2023). "The Impact of Unsprung Weight on Vehicle Dynamics". Automotive Technology Review, 7(1), 56-70.

4. Lee, S. and Park, H. (2022). "Corrosion Resistance of Titanium Alloys in Automotive Applications". Corrosion Science and Technology, 32(4), 389-401.

5. Thompson, M. (2023). "Thermal Management in High-Performance Braking Systems". SAE Technical Paper Series, 2023-01-0123.

_1739244316714.webp)

_1739170350387.webp)

_1740384907315.webp)