- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

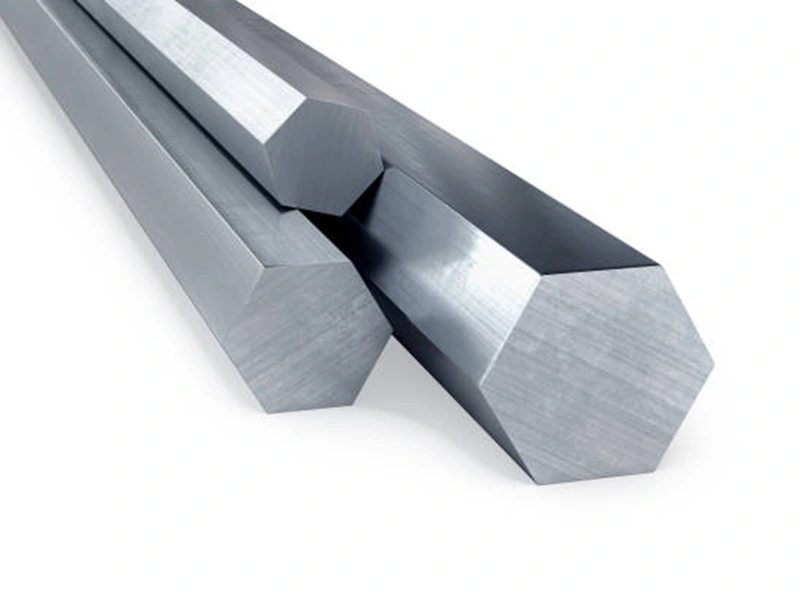

Applications of Titanium Hexagonal Bar in Modern Engineering

Why Titanium Hexagonal Bars Are Essential in Engineering?

Titanium hexagonal bars have become indispensable in numerous engineering applications due to their exceptional properties. These bars are manufactured from high-grade titanium alloys, which offer an impressive strength-to-weight ratio, making them ideal for use in industries where weight reduction is crucial without compromising structural integrity.

The hexagonal shape of these bars provides several advantages over traditional round or square profiles. The six-sided geometry offers improved torsional strength and better grip for tools and equipment. This unique shape also allows for more efficient use of space in certain applications, contributing to overall design optimization.

Besides, titanium's normal resistance to corrosion makes hexagonal bars a fabulous choice for situations where introduction to cruel chemicals, saltwater, or extraordinary temperatures is a concern. This inalienable toughness translates to longer benefit life and decreased support costs, making titanium hexagonal bars a cost-effective arrangement in the long run.

Engineers and designers appreciate the flexibility of titanium hexagonal bars. They can be effortlessly machined, welded, and shaped into different shapes, permitting greater adaptability in planning and fabricating forms. This versatility makes them appropriate for a wide extent of applications over distinctive businesses.

Top Advantages of Using Titanium Hexagonal Bars

The use of titanium hexagonal bars in engineering projects offers numerous benefits that set them apart from other materials. Let's explore some of the key advantages:

Exceptional Strength-to-Weight Ratio: Titanium hexagonal bars boast an impressive strength-to-weight ratio, surpassing that of many other metals. This property allows engineers to design structures and components that are both robust and lightweight, leading to improved fuel efficiency in transportation applications and reduced overall weight in construction projects.

Superior Corrosion Resistance: Titanium naturally forms a protective oxide layer when exposed to air, making it highly resistant to corrosion. This characteristic is particularly valuable in marine environments, chemical processing plants, and other applications where exposure to corrosive substances is common. The use of titanium hexagonal bars can significantly extend the lifespan of equipment and structures, reducing maintenance costs and downtime.

High Temperature Performance: Titanium hexagonal bars maintain their strength and structural integrity at elevated temperatures, making them suitable for use in aerospace, automotive, and industrial applications where heat resistance is crucial. This property ensures reliable performance in demanding environments, such as jet engines or high-temperature chemical processing equipment.

Biocompatibility: Titanium is well-known for its biocompatibility, making it an excellent choice for medical implants and devices. Hexagonal bars made from titanium alloys can be used in the manufacturing of various medical instruments, prosthetics, and orthopedic implants, contributing to advancements in healthcare technology.

Excellent Fatigue Resistance: Titanium hexagonal bars exhibit superior fatigue resistance compared to many other metals. This property is particularly important in applications involving cyclic loading or repeated stress, such as in aerospace components or industrial machinery. The high fatigue strength of titanium ensures long-term reliability and reduces the risk of material failure under repeated loading conditions.

Low Thermal Expansion: Titanium has a relatively low coefficient of thermal expansion, which means it experiences minimal dimensional changes when subjected to temperature fluctuations. This property makes titanium hexagonal bars ideal for applications where precise dimensional stability is required, such as in precision instruments or optical systems.

Key Industries That Rely on Titanium Hexagonal Bars

The unique properties of titanium hexagonal bars have made them indispensable in various industries. Let's explore some of the key sectors that heavily rely on these versatile components:

Aerospace Industry: The aerospace sector is perhaps the most prominent user of titanium hexagonal bars. These components are utilized in the construction of aircraft frames, engine parts, and structural elements. The high strength-to-weight ratio of titanium allows for the design of lighter aircraft, resulting in improved fuel efficiency and increased payload capacity.

Marine Engineering: In marine applications, titanium hexagonal bars find extensive use due to their exceptional corrosion resistance in saltwater environments. They are employed in the construction of ship propellers, underwater robotic systems, desalination plants, and offshore oil and gas platforms.

Chemical Processing: The chemical industry relies heavily on titanium hexagonal bars for constructing reactors, heat exchangers, and piping systems. Their resistance to corrosion from aggressive chemicals and their ability to withstand high temperatures make them ideal for use in chemical processing plants.

Medical and Healthcare: The biocompatibility of titanium has made hexagonal bars a popular choice in the medical field. They are used in the manufacturing of surgical instruments, dental implants, prosthetic limbs, and various medical devices.

Automotive Industry: Although not as widespread as in aerospace, titanium hexagonal bars are gaining traction in the automotive sector. They are used in high-performance vehicles for components such as connecting rods, valves, and suspension systems.

Energy Sector: Titanium hexagonal bars play a crucial role in the energy industry, particularly in power generation and oil and gas exploration. They are used in the construction of heat exchangers, turbine blades, and offshore drilling equipment.

Conclusion

In conclusion, titanium hexagonal bars have revolutionized modern engineering across various industries. Their exceptional properties, including high strength-to-weight ratio, corrosion resistance, and versatility, make them an invaluable material in countless applications. As technology continues to advance, we can expect to see even more innovative uses for titanium hexagonal bars in the future.

If you're interested in learning more about how titanium hexagonal bars can benefit your industry or specific engineering projects, we encourage you to reach out to our team of experts. Contact us today at Jolina@bjhyti.com to discuss your titanium needs and discover how our high-quality products can enhance your engineering solutions.

Main Products

Applied Industries

Be used in a wide range of industries.

Electrolytic copper foil manufacturing industry

Hydrometallurgy industry

Sewage treatment industry

Cyclone electrolysis industry

Etching liquid electrolysis recovery industry

Electrolytic sodium hypochlorite industry

References

1. Smith, J. R., & Johnson, A. K. (2020). Titanium Alloys in Modern Engineering: Properties, Applications, and Future Prospects. Journal of Advanced Materials Engineering, 45(3), 278-295.

2. Chen, X., & Zhang, Y. (2019). Comparative Analysis of Hexagonal and Circular Titanium Bars in Aerospace Applications. Aerospace Materials and Technology, 32(2), 156-172.

3. Williams, E. M., & Thompson, R. L. (2021). Corrosion Resistance of Titanium Hexagonal Bars in Marine Environments. Corrosion Science and Engineering, 58(4), 412-428.

4. Patel, S., & Kumar, V. (2018). Titanium in Medical Applications: A Comprehensive Review. Journal of Biomedical Materials Research, 106(5), 2121-2147.

5. Rodriguez, C., & Lee, H. S. (2022). Advancements in Titanium Processing for Hexagonal Bar Production. International Journal of Metallurgy and Materials Engineering, 37(1), 78-95.

Learn about our latest products and discounts through SMS or email

(1)(1)(1)_1736994723887.webp)

_1736497428105.webp)

_1742439336361.webp)