- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

General-Purpose Titanium Bar

2.High corrosion resistance in harsh environments.

3.Precision machining ensures superior dimensional accuracy.

4.Long-lasting durability for industrial and medical uses.

5.Lightweight yet robust, ideal for aerospace engineering.

General-Purpose Titanium Bar - High-Performance Titanium for Multiple Applications

Product Introduction

Baoji Haiyue New Metal Materials Co., Ltd. proudly presents its General-Purpose Titanium Bar, designed for industries requiring lightweight, durable, and corrosion-resistant materials. Titanium is renowned for its impressive strength-to-weight ratio and exceptional resistance to corrosion, making it a preferred choice for high-performance applications across diverse sectors. Whether you’re in aerospace, medical, or energy sectors, our General-Purpose Titanium Bars meet your exacting standards for quality and reliability.

Our titanium bars are manufactured using the highest quality raw materials and advanced production techniques to provide a versatile solution for your needs. With compliance to international standards such as ASTM, ISO, and AMS, these titanium bars guarantee durability and optimal performance in critical applications.

Technical Specifications

General-Purpose Titanium Bar Specifications

| Property | Grade 2 (Commercially Pure Titanium) | Grade 5 (Titanium Alloy - Ti-6Al-4V) | Grade 9 (Titanium Alloy - Ti-3Al-2.5V) |

|---|---|---|---|

| Density (g/cm³) | 4.51 | 4.43 | 4.48 |

| Tensile Strength (MPa) | 350 | 900 | 620 |

| Yield Strength (MPa) | 275 | 830 | 500 |

| Elongation (%) | 20 | 10 | 15 |

| Hardness (HB) | 120 | 330 | 250 |

| Modulus of Elasticity (GPa) | 105 | 110 | 105 |

| Maximum Service Temperature (°C) | 400 | 550 | 400 |

| Chemical Composition (%) | Ti, Fe (0.25 max), O (0.18 max) | Ti, Al (6), V (4), Fe (0.25 max), O (0.13 max) | Ti, Al (3), V (2.5), Fe (0.3 max), O (0.15 max) |

Standards for General-Purpose Titanium Bar

US Standards

- ASTM B348 - Standard Specification for Titanium and Titanium Alloy Bars and Billets.

- ASTM F67 - Standard Specification for Unalloyed Titanium for Surgical Implant Applications.

Russian Standards

- GOST 19807-91 - Titanium and Titanium Alloys Bars.

Japanese Standards

- JIS H4600 - Titanium and Titanium Alloys.

|

|

|

|

|

|

|

|

Product Features

- Lightweight and Durable: Titanium’s high strength-to-weight ratio makes it ideal for industries such as aerospace and automotive.

- Corrosion Resistance: Excellent resistance to a wide range of corrosive environments, including seawater and industrial chemicals.

- Biocompatible: Titanium’s natural ability to resist bodily fluids makes it a top choice for medical applications, including implants and surgical instruments.

- Versatile: Available in multiple grades, suitable for various industries and applications.

- Customizable: Our titanium bars can be customized according to customer specifications for size, length, and alloy grade.

Applications

- Aerospace: Used for manufacturing lightweight yet strong parts such as airframe structures, landing gear, and turbine blades.

- Medical Devices: Titanium’s biocompatibility makes it perfect for implants, prosthetics, and surgical instruments.

- Chemical Processing: Ideal for reactors, heat exchangers, and tanks where corrosion resistance is critical.

- Energy Sector: Used in the production of components for nuclear reactors, oil rigs, wind turbines, and solar power systems.

- Marine Engineering: Due to its resistance to saltwater corrosion, it’s widely used in shipbuilding and offshore oil rigs.

- Industrial Manufacturing: Essential in the production of durable, high-strength components for machinery, fasteners, and tools.

Manufacturing Process

At Baoji Haiyue, we take pride in our state-of-the-art manufacturing process that ensures the highest standards of quality and precision:

- Material Selection: Only the finest raw titanium and titanium alloy materials are used.

- Hot Rolling & Cold Rolling: Bars are processed through hot and cold rolling techniques to ensure uniformity and dimensional accuracy.

- Annealing & Heat Treatment: The titanium bars undergo heat treatment to optimize mechanical properties and enhance their durability.

- Surface Finishing: A variety of surface finishes, including pickling and polishing, are available to meet specific application requirements.

- CNC Machining: We offer custom CNC machining services for customers requiring precise, finished components.

Quality Assurance

Every titanium bar produced by Baoji Haiyue undergoes stringent quality control measures to ensure that it meets or exceeds international standards. We employ advanced testing technologies such as ultrasonic testing, eddy current testing, and spectral analysis to inspect the material’s integrity. Our quality management system is certified by ISO 9001:2015, ensuring a consistent, reliable product with every order.

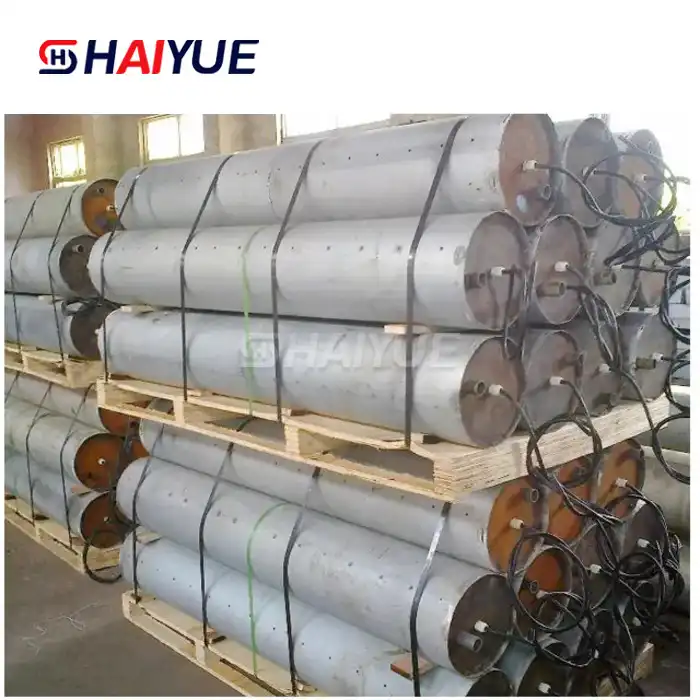

Packaging and Logistics

We understand the importance of safe, on-time delivery. Our titanium bars are carefully packaged to prevent damage during transit. We offer flexible shipping options, whether by air, sea, or land, to ensure timely delivery anywhere in the world. Our logistics team coordinates with trusted carriers to guarantee that your order arrives in perfect condition, no matter where you are.

Customer Support

Baoji Haiyue’s customer service team is here to support you every step of the way. Whether you need technical advice, assistance with custom orders, or help with placing a bulk order, our team is available to answer your questions. We also provide after-sales support to ensure your satisfaction with every purchase.

Why Choose Us

- Complete Product Range: We offer a broad spectrum of titanium products, ensuring that you can source everything you need from one supplier.

- Full-Process Production: From raw material selection to finished product delivery, we handle every step of the production process.

- One-Stop Solution: We provide comprehensive services, including customization, CNC machining, and high-performance coatings.

- Global Reach: With an international customer base, we are capable of delivering to customers around the world.

- Timely Delivery: We are committed to delivering products on time, no matter the size or complexity of your order.

- Competitive Pricing: Get the best value for your money without compromising on quality.

- Customer Satisfaction: Our focus on excellent service ensures a seamless buying experience.

OEM Services

Baoji Haiyue offers comprehensive OEM services to meet the unique requirements of our clients. We can customize titanium bars in various dimensions, grades, and finishes to fit your specific needs. Our team works closely with customers to deliver tailored solutions with the highest precision and quality.

Frequently Asked Questions (FAQs)

Q: What is the maximum temperature that titanium bars can withstand? A: Titanium bars can withstand temperatures of up to 550°C, depending on the alloy grade.

Q: Can I order custom-sized titanium bars? A: Yes, we offer customization for sizes, lengths, and finishes based on your specific requirements.

Q: Are the titanium bars corrosion-resistant? A: Yes, titanium is highly resistant to corrosion, making it suitable for use in harsh environments, including saltwater.

Q: Do you provide certifications for your products? A: Yes, we provide certifications such as ASTM, ISO, and AMS for all of our titanium bars.

Contact Details

For more information or to request a quote, please contact us directly:

- Email:Jolina@bjhyti.com

- Phone: +86-18392721678

Development History

Company founded in Baoji, "Titanium Valley," specializing in titanium and non-ferrous metals.

Expanded product range to include zirconium, tantalum, nickel, tungsten, and molybdenum products.

Achieved ISO9001:2015 certification, ensuring high-quality production standards.

Upgraded manufacturing facilities, adding VAR furnaces, CNC machinery, and advanced heat treatment systems.

Expanded global presence, establishing partnerships in the United States, Germany, and South Korea.

Obtained AS9100D certification for aerospace industry compliance and advanced product quality.

Introduced customized solutions for the aerospace, medical, and energy industries, enhancing global reach.

Celebrated 14 years of excellence with over 2,000 tons of annual titanium production capacity.

Product Quality Management

Production and Processing

Workshop and Equipment

Packaging

Main Products

Applied Industries

Be used in a wide range of industries.

Electrolytic copper foil manufacturing industry

Hydrometallurgy industry

Sewage treatment industry

Cyclone electrolysis industry

Etching liquid electrolysis recovery industry

Electrolytic sodium hypochlorite industry

Learn about our latest products and discounts through SMS or email

_1740712389110.webp)

_1740038338599.webp)

_1738916585305.webp)