- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

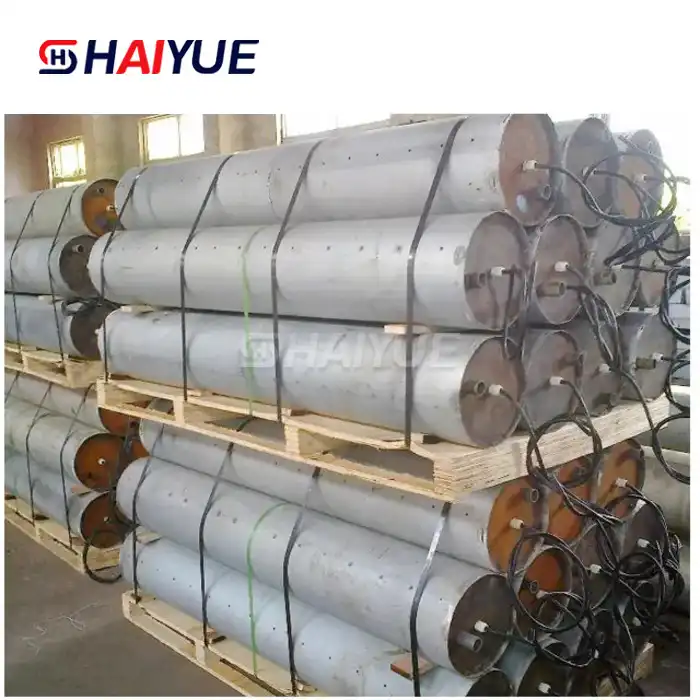

Titanium anodes for ship cathodic protection

Coating: MMO coatings optimized for long-lasting cathodic protection in marine environments.

Size: Custom lengths and diameters available to meet specific ship requirements.

Surface Treatment: Available surface treatments include sand blasting, acid cleaning, and polished finishes for effective protection.

Production time: 15 working days for standard orders, with options for faster processing.

Introduction

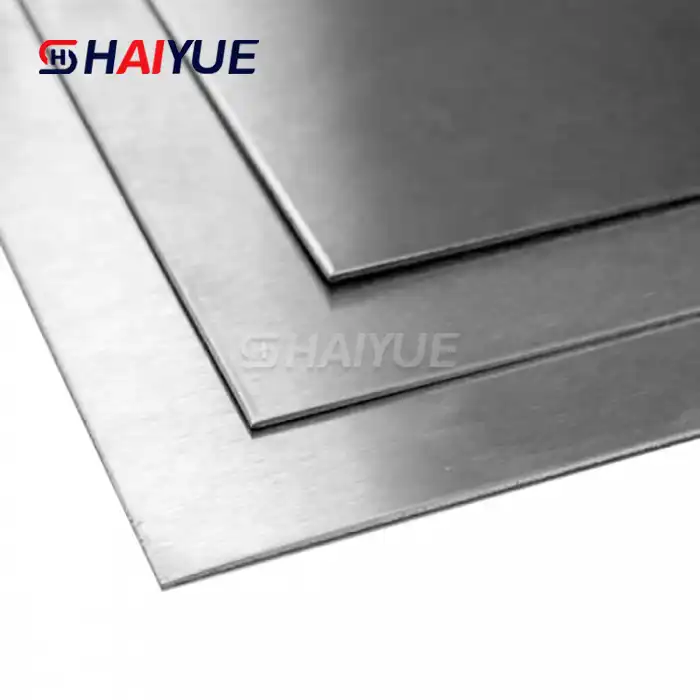

Titanium anodes are a critical component in the cathodic protection systems used for preventing corrosion on ships and marine structures. These anodes are highly resistant to corrosion, lightweight, and have an extended lifespan, making them an ideal solution for protecting metal surfaces in harsh marine environments. Whether you’re managing a fleet of ships or handling large-scale marine infrastructure projects, our titanium anodes provide reliable, long-term protection against saltwater corrosion.

Technical Specifications

| Specification | Details |

|---|---|

| Material | Titanium (Grade 1 or Grade 2) |

| Diameter | Customizable (from 10mm to 500mm) |

| Length | Customizable (up to 10 meters) |

| Weight | Varies based on size |

| Corrosion Resistance | Excellent, with high resistance to saltwater and other aggressive environments |

| Operating Temperature | Up to 600°C |

|

|

|

|

|

|

|

|

Key Features

- Durability: Titanium’s exceptional corrosion resistance ensures a longer lifespan in challenging saltwater environments.

- Lightweight: Despite their strength, titanium anodes are much lighter than other materials, reducing the overall weight burden on the vessel.

- High Efficiency: Designed to provide continuous protection without requiring frequent replacement, reducing maintenance costs.

- Custom Sizes: We offer titanium anodes in various sizes to meet specific requirements for different ship types and marine applications.

- Eco-Friendly: Our manufacturing processes prioritize sustainability, ensuring a minimal environmental impact.

Applications

Titanium anodes are predominantly used in:

- Shipbuilding: Protecting hulls, propellers, and underwater structures from corrosion.

- Marine Infrastructure: Protecting docks, piers, and offshore oil rigs.

- Aquaculture: Ensuring the longevity of equipment used in fish farming and underwater installations.

- Energy & Offshore Engineering: Preventing damage to underwater pipelines and energy infrastructure exposed to harsh conditions.

Manufacturing Process

At Baoji Haiyue, we utilize advanced manufacturing techniques, including cold and hot rolling, forging, and CNC machining, to produce high-quality titanium anodes. Our facility is equipped with cutting-edge equipment like VAR furnaces, which ensure that the titanium anodes meet international standards for durability and performance. We also offer custom solutions to meet your specific application needs.

Quality Assurance

Our titanium anodes are rigorously tested for strength, corrosion resistance, and reliability. We use state-of-the-art testing methods, including ultrasonic and eddy current testing, to ensure that each batch meets industry standards. Every product undergoes thorough inspection at every stage of production, guaranteeing superior quality and performance.

Packaging and Logistics

We understand the importance of timely delivery and secure packaging. Our titanium anodes are carefully packed to prevent damage during transport. With our global logistics network, we ensure fast delivery to your location, whether you’re based in North America, Europe, Asia, or beyond.

Customer Support

Our customer support team is here to assist you at every step. From selecting the right product to after-sales support, we ensure you receive expert guidance and assistance. We’re always ready to help with any inquiries regarding product specifications, custom orders, or delivery schedules.

Why Choose Us

- Complete Product Range: We offer a wide variety of titanium anodes for ship cathodic protection, ensuring you can find the perfect fit for your project.

- Full-Process Production: From material sourcing to final delivery, we handle every stage of the production process, ensuring quality and consistency.

- Global Sales and Agency: Our products are sold worldwide, with dedicated agents in various countries to provide you with localized support.

- Fast Delivery: With our robust production capabilities and efficient logistics network, we guarantee timely deliveries, even for bulk orders.

- Reputation: Baoji Haiyue has built a reputation for high-quality products and outstanding customer service.

- Customized Products: We offer tailored solutions based on your specific needs, whether you require special sizes, shapes, or additional features.

- Timely Global After-Sales Service: Our team is available to support you even after your purchase, ensuring complete satisfaction.

Development History

Company founded in Baoji, "Titanium Valley," specializing in titanium and non-ferrous metals.

Expanded product range to include zirconium, tantalum, nickel, tungsten, and molybdenum products.

Achieved ISO9001:2015 certification, ensuring high-quality production standards.

Upgraded manufacturing facilities, adding VAR furnaces, CNC machinery, and advanced heat treatment systems.

Expanded global presence, establishing partnerships in the United States, Germany, and South Korea.

Obtained AS9100D certification for aerospace industry compliance and advanced product quality.

Introduced customized solutions for the aerospace, medical, and energy industries, enhancing global reach.

Celebrated 14 years of excellence with over 2,000 tons of annual titanium production capacity.

Product Quality Management

Production and Processing

Workshop and Equipment

Packaging

Main Products

Applied Industries

Be used in a wide range of industries.

Electrolytic copper foil manufacturing industry

Hydrometallurgy industry

Sewage treatment industry

Cyclone electrolysis industry

Etching liquid electrolysis recovery industry

Electrolytic sodium hypochlorite industry

OEM Services

We offer OEM services to meet the unique requirements of your business. Whether you need specific shapes, sizes, or additional coatings, our team works closely with you to deliver the precise solution for your cathodic protection needs.

Frequently Asked Questions (FAQs)

Q: What are the main benefits of using titanium anodes for cathodic protection?

A: Titanium anodes offer excellent corrosion resistance, long-lasting durability, and lightweight properties, making them ideal for shipbuilding and marine environments.

Q: Can I get customized titanium anodes for my specific needs?

A: Yes, we offer customized solutions, including various sizes, shapes, and coatings, to meet your unique requirements.

Q: How long do titanium anodes last?

A: Titanium anodes can last significantly longer than other materials, offering years of reliable protection with minimal maintenance.

Q: Are your products certified?

A: Yes, our products are certified to meet international standards such as ASTM, ISO, and AMS.

Contact Details

For inquiries, quotes, or additional information, feel free to contact us directly:

- Email: Jolina@bjhyti.com

- Phone: +86-18392721678

Learn about our latest products and discounts through SMS or email

_1750228284774.webp)