- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

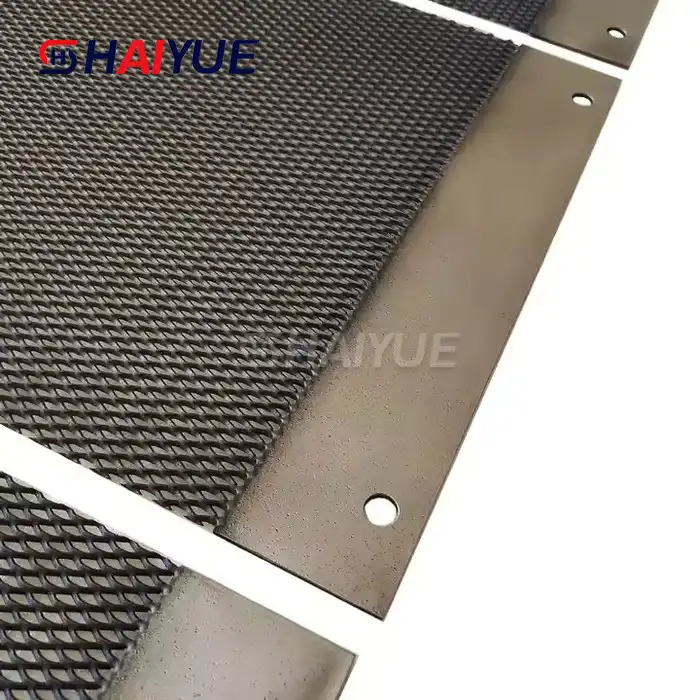

Titanium anode for hydrogen production by electrolysis of seawater

Coating: MMO coatings or specialized coatings for maximizing hydrogen production from seawater.

Size: Customizable to fit different electrolytic cells used in hydrogen production processes.

Surface Treatment: Options include sand blasting, acid cleaning, and polished finishes to improve the anode's efficiency.

Production time: 15 working days for production and delivery.

Product Introduction

Titanium anodes play a critical role in the electrolysis of seawater, enabling the efficient production of hydrogen. At Baoji Haiyue New Metal Materials Co., Ltd., we offer top-quality titanium anodes specifically designed for hydrogen production through seawater electrolysis. Our anodes are engineered to deliver superior performance, corrosion resistance, and durability in the demanding conditions of electrolysis systems.

By utilizing advanced manufacturing techniques, we ensure that our titanium anodes are built to withstand the harsh environment of seawater electrolysis, providing long-lasting and reliable performance for renewable energy applications.

Technical Specifications

| Property | Specification |

|---|---|

| Material | High-Grade Titanium (Grade 2) |

| Dimensions | Customizable sizes available |

| Surface Treatment | Oxidized or Coated |

| Max Operating Temperature | 600°C |

| Electrolyte Compatibility | Seawater, Chlorine Solutions |

| Corrosion Resistance | Excellent in seawater |

| Feature | Description |

|---|---|

| Durability | Long-lasting, high resistance to corrosion |

| Efficiency | Enhanced electrolysis efficiency |

| Custom Solutions | Available in various sizes and specifications |

| Certifications | ISO 9001, ASTM, AMS |

|

|

|

|

|

|

|

|

Product Features (Key Features)

- High Corrosion Resistance: Titanium is highly resistant to corrosion, especially in the aggressive environment of seawater electrolysis, ensuring longevity and reduced maintenance.

- Excellent Electrolytic Efficiency: Our anodes improve the efficiency of hydrogen production through optimal conductivity and surface area, providing faster reaction rates.

- Customizable Sizes: We offer titanium anodes in a variety of sizes, ensuring a perfect fit for your specific electrolysis system.

- Long-Lasting Durability: Designed to last under high-temperature and high-current conditions, our titanium anodes minimize downtime and maintenance costs.

Applications

- Hydrogen Production: Essential for the electrolysis of seawater to produce clean hydrogen energy.

- Renewable Energy: Used in green energy applications, particularly in hydrogen fuel cell production.

- Marine Engineering: Perfect for offshore platforms and marine environments requiring corrosion-resistant materials.

- Chemical Processing: Suitable for harsh chemical environments where titanium’s resistance to corrosion is critical.

Manufacturing Process

At Baoji Haiyue, we utilize state-of-the-art facilities to manufacture our titanium anodes. The process begins with high-quality titanium raw materials, which are carefully selected and inspected for purity. Our advanced cold and hot rolling mills, forging presses, and surface treatment facilities ensure the titanium is shaped and treated to meet the most demanding specifications. The result is an anode that excels in both performance and longevity.

Quality Assurance

Our titanium anodes are rigorously tested to ensure they meet international quality standards. We employ ultrasonic testing, spectral analysis, and eddy current testing to assess each product's structural integrity and corrosion resistance. With certifications such as ISO 9001 and AMS, you can be confident that our products will perform reliably in your applications.

Packaging and Logistics

Our titanium anodes are carefully packaged to avoid damage during transit. We ensure that all products are securely wrapped and protected to preserve their quality upon delivery. Our global logistics network ensures timely delivery to any location, minimizing lead times and meeting urgent customer needs.

Customer Support

Our dedicated customer support team is available to assist with any inquiries, product customization requests, or technical support. We pride ourselves on providing excellent after-sales service, ensuring that your experience with us is smooth from order to delivery.

Why Choose Us

- Comprehensive Product Range: From titanium anodes to other advanced materials, we offer a complete range of products tailored to your needs.

- Global Sales and Agency: We serve clients in over 20 countries, ensuring worldwide reach and support.

- Fast Delivery and Timely Service: Our efficient supply chain guarantees quick delivery, even for customized products.

- Reliable After-Sales Support: Our customer service extends globally, offering fast response times and door-to-door support.

Development History

Company founded in Baoji, "Titanium Valley," specializing in titanium and non-ferrous metals.

Expanded product range to include zirconium, tantalum, nickel, tungsten, and molybdenum products.

Achieved ISO9001:2015 certification, ensuring high-quality production standards.

Upgraded manufacturing facilities, adding VAR furnaces, CNC machinery, and advanced heat treatment systems.

Expanded global presence, establishing partnerships in the United States, Germany, and South Korea.

Obtained AS9100D certification for aerospace industry compliance and advanced product quality.

Introduced customized solutions for the aerospace, medical, and energy industries, enhancing global reach.

Celebrated 14 years of excellence with over 2,000 tons of annual titanium production capacity.

Product Quality Management

Production and Processing

Workshop and Equipment

Packaging

Main Products

Applied Industries

Be used in a wide range of industries.

Electrolytic copper foil manufacturing industry

Hydrometallurgy industry

Sewage treatment industry

Cyclone electrolysis industry

Etching liquid electrolysis recovery industry

Electrolytic sodium hypochlorite industry

OEM Services

We offer OEM services to meet your specific requirements. Whether you need custom dimensions, coatings, or special properties, our engineering team will work with you to create the perfect solution.

Frequently Asked Questions (FAQs)

Q: What is the lifespan of the titanium anode for seawater electrolysis?

A: Our titanium anodes are designed for long-term use, with a lifespan of up to 10 years, depending on operating conditions.

Q: Can the titanium anode be used for other types of electrolysis?

A: Yes, our anodes are suitable for various types of electrolysis, including chlorine and water treatment systems.

Q: Do you offer customized sizes for the anodes?

A: Absolutely! We offer full customization based on your specific requirements.

Contact Details

For more information or to request a quote, please contact us:

Email: Jolina@bjhyti.com

Phone: +86-18392721678

Learn about our latest products and discounts through SMS or email

_1738830079027.webp)

_1742782628752.webp)