- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Titanium Wheel Studs in Stock

2.Superior corrosion resistance in extreme environments.

3.Precision threading ensures secure and reliable fastening.

4.High-temperature tolerance for demanding industrial uses.

5.Custom designs available to meet specific requirements.

Product Overview

Our Titanium Wheel Studs in Stock are manufactured from high-strength Grade 5 titanium alloy (Ti-6Al-4V) and are ready for immediate shipment. These wheel studs are ideal for performance, motorsport, and high-end vehicle applications where strength-to-weight ratio, corrosion resistance, and thermal stability are critical.

These pre-manufactured studs meet strict dimensional and mechanical standards, ensuring fast installation and reliable performance. Available in various popular thread sizes and lengths, they are compatible with most European, Japanese, and American vehicles.

Key Specifications

| Item | Specification |

|---|---|

| Product Name | Titanium Wheel Studs (In Stock) |

| Material | Titanium Alloy Grade 5 (Ti-6Al-4V) |

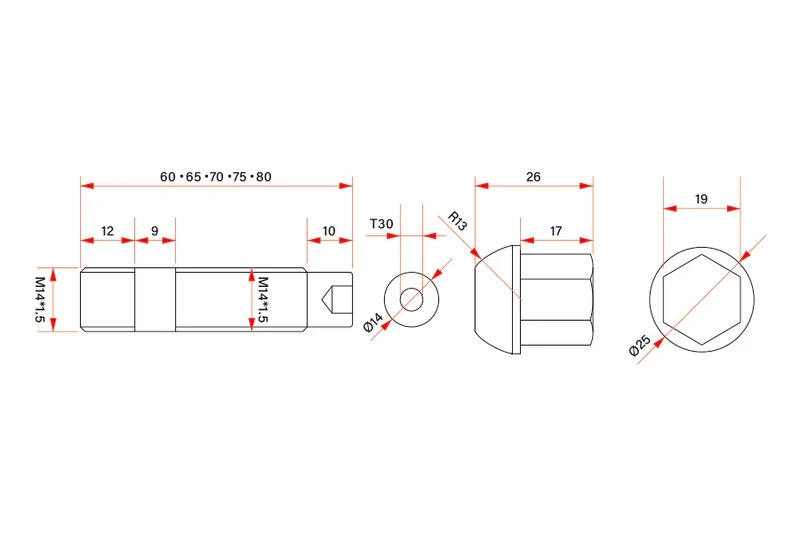

| Thread Sizes Available | M12×1.25 / M12×1.5 / M14×1.25 / M14×1.5 |

| Length Options | 60 mm / 65 mm / 70 mm / 75 mm / 80 mm |

| Tensile Strength | ≥ 950 MPa |

| Yield Strength | ≥ 880 MPa |

| Finish Options | Polished / Burnt Blue / Natural Titanium |

| Heat Resistance | Up to 600°C |

| Corrosion Resistance | Excellent in salt, water, and chemical environments |

| Weight Reduction | 40%–50% lighter than steel studs |

| Applications | Street Cars / Racing / Off-Road / Aftermarket Upgrades |

| Packaging | Individually packed or kit format (optional) |

| Delivery Time | Ships within 1–3 business days (for in-stock models) |

Titanium Wheel Stud and Lug Nut Size Combinations

| Stud Size (Thread × Pitch) | Stud Length (mm) | Compatible Lug Nut Thread | Typical Application |

|---|---|---|---|

| M12×1.25 | 60 / 70 / 80 / 90 / 100 | M12×1.25 | Nissan, Subaru, aftermarket racing wheels |

| M12×1.5 | 60 / 70 / 80 / 90 / 100 | M12×1.5 | Toyota, Honda, BMW (older models) |

| M14×1.25 | 60 / 70 / 80 / 90 / 100 | M14×1.25 | BMW, Mini Cooper, aftermarket applications |

| M14×1.5 | 60 / 70 / 80 / 90 / 100 | M14×1.5 | Audi, Volkswagen, Mercedes-Benz, Porsche |

| 1/2"-20 UNF | 60 / 70 / 80 / 90 / 100 | 1/2"-20 UNF | Ford, Dodge, some American muscle cars |

|

|

|

|

Product Features of Titanium Wheel Bolt and Nut Kits

-

Lightweight Construction

Made from Grade 5 titanium (Ti-6Al-4V), these bolts offer up to 45% weight reduction compared to standard steel bolts, effectively reducing unsprung mass and improving vehicle handling and acceleration. -

High Strength and Durability

With tensile strength exceeding 950 MPa, titanium wheel bolts provide excellent load-bearing capacity and long service life, even under high-stress driving conditions. -

Superior Corrosion Resistance

Naturally resistant to rust, salt, and chemicals, ideal for use in coastal, wet, or snowy environments without degradation over time. -

Excellent Heat Resistance

Performs reliably under extreme temperatures generated by high-speed braking, making them suitable for racing and track use. -

Precision CNC Machining

Manufactured with high precision to ensure perfect thread engagement, fitment, and uniform torque distribution, reducing the risk of wheel loosening or thread damage. -

Anti-Galling Thread Design

Titanium's inherent galling risk is minimized through specialized surface treatments and threading accuracy, ensuring smooth and safe installation and removal. -

Attractive Appearance

Available in raw titanium, anodized colors (blue, gold, black, purple), or burnt finish for a visually striking look, enhancing the appearance of any performance vehicle. -

Customizable Options

Offers multiple thread sizes (M12, M14, etc.), thread pitches (1.25 / 1.5), bolt lengths, head shapes (hex, spline), and seating types (cone, ball) to fit a wide variety of vehicles. -

Environmentally Friendly Material

100% recyclable titanium with no toxic coatings, aligning with sustainable automotive trends.

Application Areas

-

Primary Application Areas

-

Racing and Track Vehicles

Ideal for drift, circuit, rally, time attack, and drag racing, where repeated high-stress disassembly and reinstallation occur. -

Modified Street and Performance Cars

Used by enthusiasts upgrading to lightweight wheels or wide-body kits, or who require extended studs to accommodate wheel spacers. -

Compatibility Notes

-

Available in M12×1.25, M12×1.5, M14×1.25, M14×1.5, and 1/2"-20 UNF thread sizes.

-

Compatible with corresponding open-end or closed-end titanium lug nuts.

-

Custom lengths and coatings (e.g., burnt blue, black anodized) available for both functional and aesthetic customization.

-

Luxury and Sports Cars

Common on vehicles such as BMW, Porsche, Audi, Mercedes-Benz, Lexus, Nissan GTR, and Subaru WRX STI, offering enhanced performance and aesthetic appeal. -

Aftermarket Wheel and Brake Conversions

Supports large brake kits or custom wheel offsets requiring longer or stronger wheel studs. -

Off-Road and All-Terrain Vehicles

Suitable for lifted trucks and 4x4 applications requiring rugged, anti-corrosion fasteners in wet or harsh environments. -

OEM Replacement or Lightweight Upgrades

Replaces standard steel wheel studs to reduce unsprung weight and eliminate corrosion concerns, enhancing responsiveness and longevity.

|

|

|

|

OEM and Custom Services

We offer full-scale OEM production for Titanium Wheel Bolt and Nut Kits, tailored to your brand requirements. This includes logo engraving, customized packaging, and part labeling to support private-label and distributor programs.

-

Custom Dimensions and Specifications

Titanium wheel bolts can be customized in thread size (e.g., M12x1.25, M14x1.5, 1/2"-20), length, head shape (hex, spline, 12-point), and seat type (cone, ball, flat) to fit specific vehicle models or aftermarket wheels. -

Surface Treatment Options

Choose from multiple finishes such as raw polished titanium, PVD coating, anodizing (blue, gold, purple, black), or burned rainbow for unique aesthetics and added surface protection. -

Material Grade Flexibility

While standard models use premium Gr5 (Ti-6Al-4V) titanium alloy, we also offer Gr2 or other titanium grades based on your application needs and cost targets. -

Thread Design Customization

We provide metric or inch thread customization, including left-hand threading, anti-galling treatments, and fine/coarse pitch to match specific hub or wheel designs. -

Batch and Prototyping Services

Whether you need small-volume prototyping for new projects or large-scale mass production for wholesale supply, we support flexible MOQs and fast lead times. -

Packaging and Branding Solutions

Custom packaging solutions include branded boxes, blister packs, sets with matching washers or nuts, and multilingual labels for global distribution. -

Technical Support and Co-Engineering

Our engineering team can collaborate with you to develop custom bolt designs for unique applications, including motorsport, EVs, or military use, offering CAD drawings and strength analysis upon request. -

Global Shipping and Logistics Support

We assist with international freight coordination, compliance with local import standards, and fast air/sea delivery to meet your supply chain needs.

To provide you with an accurate quotation, please kindly fill out the details below and submit the form.

The more complete the information, the faster and more precise our response will be.

Please include the following:

Product Name: __________________________

Lug Nut Size: _______

Lug Stud Size:_______

Order Quantity: _______ pcs

Surface Treatment: __________________________

Material: __________________________

Required Delivery Time: __________________________

Shipping Destination: __________________________ (Please include country and postal code)

Drawing File: Please email your design (JPEG, PNG, PDF, or Word format) with a minimum resolution of 300 DPI to ensure clarity.

Contact Details

For more information or to request a quote, feel free to contact us:

- Email:Jolina@bjhyti.com

- Phone: +86-18392721678

Ready to upgrade your wheels with high-quality polished lug nuts? Contact us today to discuss your needs and receive a customized quote!

Product Quality Management

Production and Processing

Workshop and Equipment

Packaging and Delivery

Standard packaging includes foam tray and export carton

Custom retail packaging options available

Lead time is 5 to 10 days for stock sizes and 10 to 20 days for custom sizes

Shipping available via DHL FedEx UPS air freight or sea freight

Global export support with full documentation

Main Products

FAQ

-

What grades of titanium are available for wheel studs?

- We offer Titanium Grade 5 (Ti-6Al-4V) and Grade 4, which are ideal for high-performance applications.

-

Can I get custom sizes for my wheel studs?

- Yes, we provide customized sizes based on your specific needs. Contact us for more details.

-

How can I ensure the quality of the wheel studs?

- Our wheel studs undergo stringent quality control, including mechanical testing and corrosion resistance tests to ensure top-tier performance.

-

What is the delivery time for Titanium Wheel Studs?

- Delivery times vary depending on order volume and customization. Typically, we ship within 7-14 business days.

Contact Details

For quotes, product inquiries, or additional information, feel free to contact us:

- Email:Jolina@bjhyti.com

- Phone: +86-18392721678

Learn about our latest products and discounts through SMS or email

_1740712389110.webp)

_1750228313982.webp)