- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Factory-Made Titanium Alloy Lug Nut

Condition: Annealed / Polished

Color: Red, yellow, purple, blue, burnt blue, gray, silver, black

Moq:100pcs

Product Overview

The Factory-Made Titanium Alloy Lug Nut is precision-manufactured from high-performance titanium materials such as Grade 2 or Grade 5 (Ti-6Al-4V), delivering exceptional strength, ultra-lightweight properties, and corrosion resistance. Designed for use in automotive wheels across various industries including motorsports, tuning, and OEM production, these lug nuts are ideal for high-performance applications that demand durability, precision, and style. With in-house factory production, quality and customization are strictly controlled to meet diverse client requirements.

Key Specifications

-

Product Name: Factory-Made Titanium Alloy Lug Nut

-

Material Options: Titanium Grade 2 (Commercially Pure), Titanium Grade 5 (Ti-6Al-4V)

-

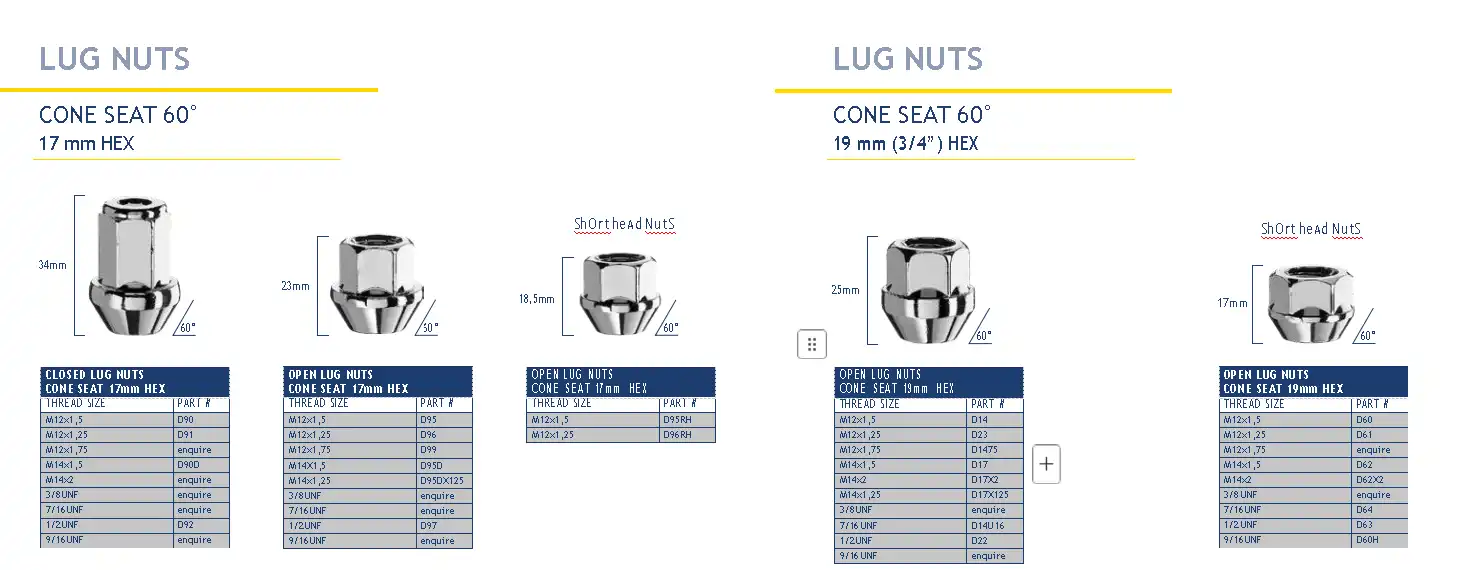

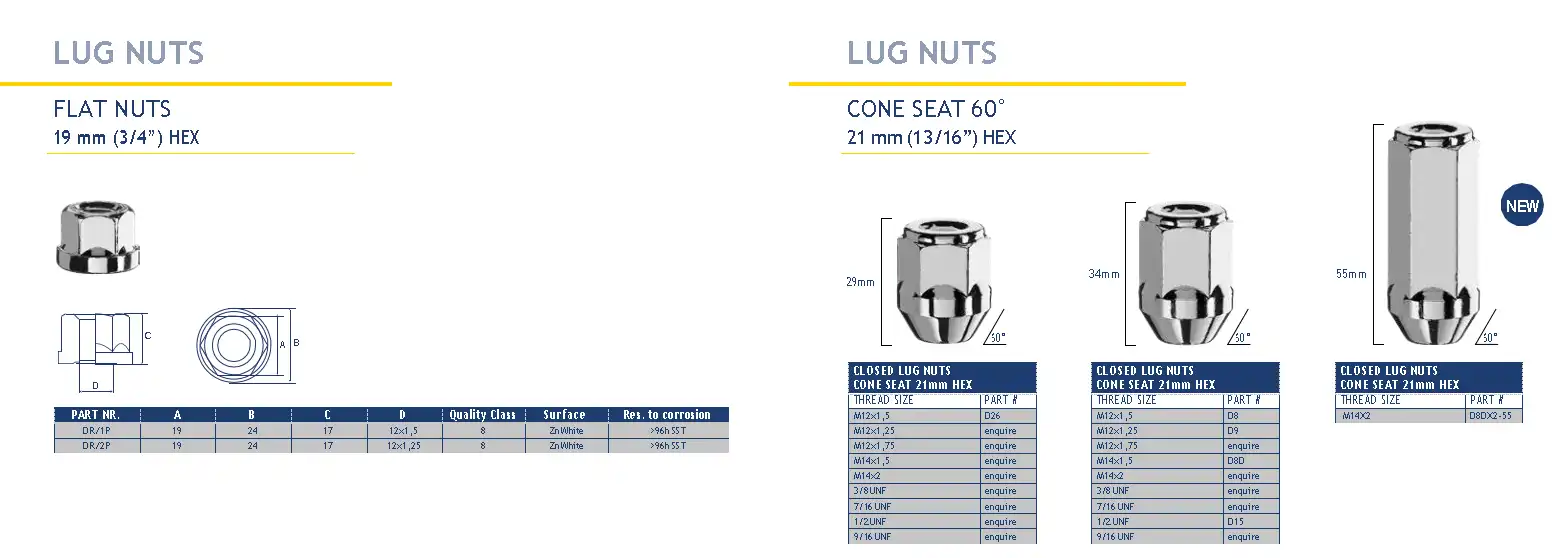

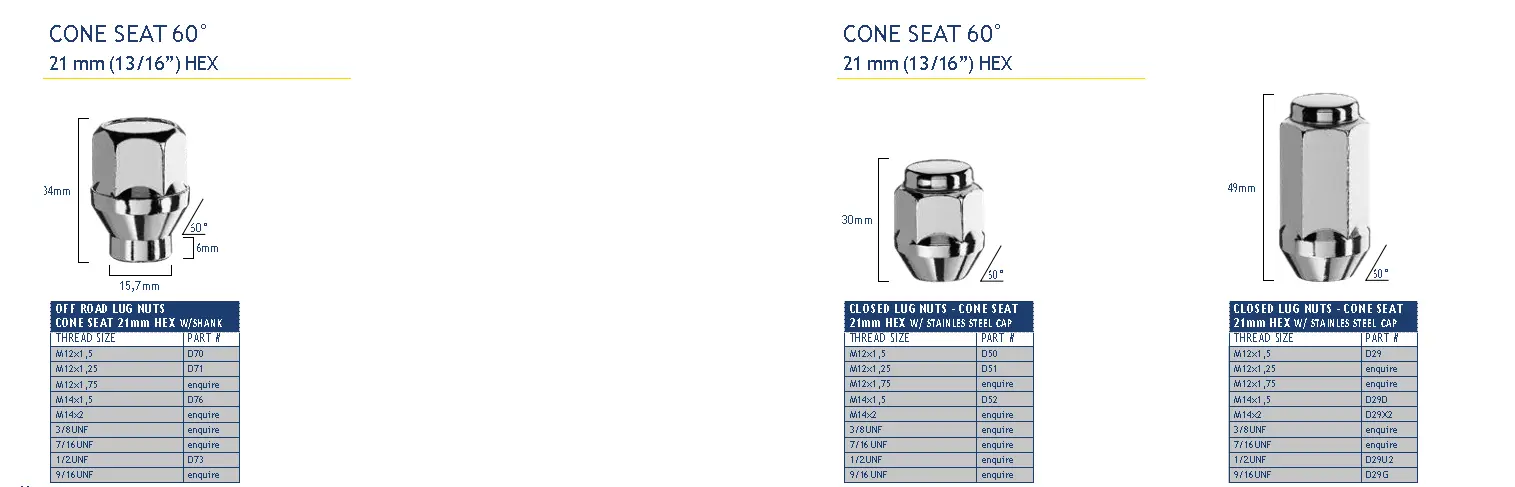

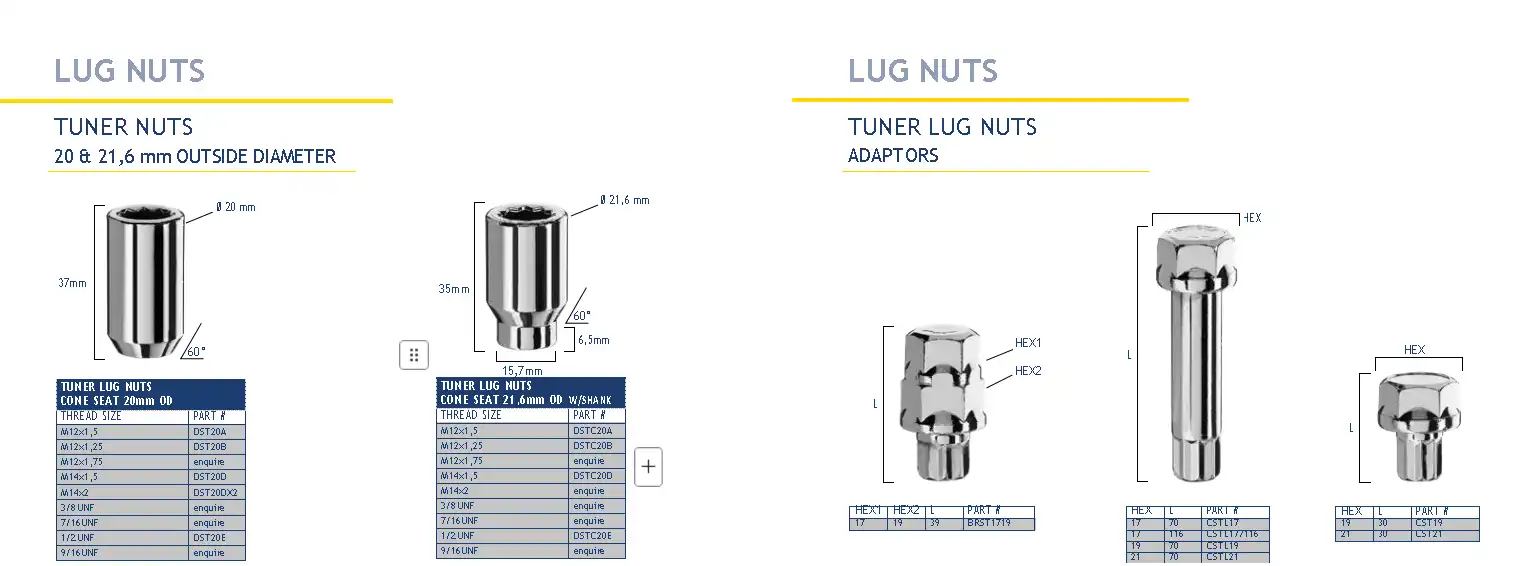

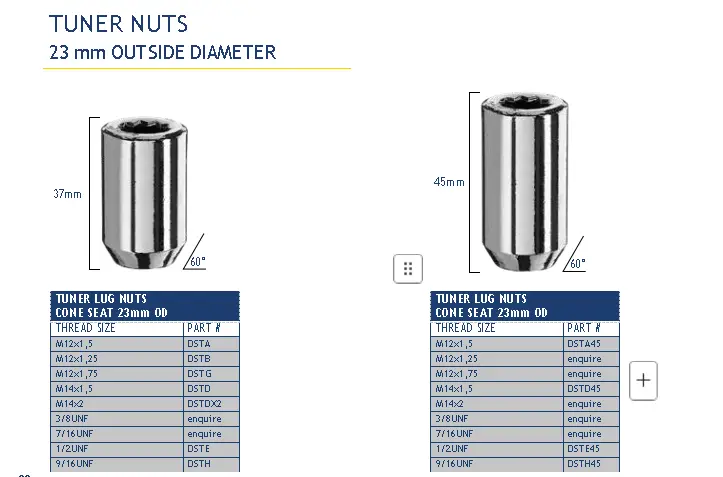

Thread Sizes: M12×1.25, M12×1.5, M14×1.5, M14×2.0, UNF/UNC, or customized

-

Hex Sizes: 17mm, 19mm, 21mm, or per drawing

-

Seat Types: 60° Tapered Seat, Ball Seat, Flat Seat

-

Overall Length: 25mm, 30mm, 35mm, 40mm, or customized

-

Weight: 15g–28g per piece depending on size and design

-

Finish Options: Natural Titanium, Burnt Blue, Gold, Rainbow, Black, Custom Anodizing

-

Mechanical Properties:

-

Tensile Strength: ≥ 950 MPa (for Gr5)

-

Hardness: ≥ HRC 35

-

-

Standards: ISO 898-2, DIN, JIS, ANSI available

-

Production Method: CNC Machined from titanium bar stock

-

Packaging: Foam tray with export carton or custom retail box

Product Features

-

Precision Machined: CNC processing ensures accurate threading and dimensional consistency for perfect fitment

-

Ultra Lightweight: Titanium is about 40% lighter than steel, reducing rotational mass and improving vehicle dynamics

-

High Strength: Grade 5 titanium offers superior tensile strength, ideal for performance and racing vehicles

-

Corrosion Resistant: Titanium naturally resists rust, oxidation, and road salt, ensuring long-term durability in all environments

-

Heat Resistant: Performs well under high-temperature conditions such as hard braking and track use

-

Aesthetic Versatility: Anodized and burnt finishes provide stylish appearance for aftermarket wheel builds

-

Environmentally Friendly: 100% recyclable material with long lifespan and low maintenance needs

-

Factory Controlled Quality: Produced in-house to ensure consistent quality, material traceability, and timely delivery

Application Areas

1. Racing Cars

Widely used in professional motorsport environments including circuit racing, time attack, drag racing, and drift competitions. The high strength and low weight help reduce unsprung mass and increase wheel responsiveness.

2. Performance Street Vehicles

Ideal for high-performance street cars that demand both visual appeal and technical performance. Titanium lug nuts provide enhanced aesthetics while maintaining structural integrity under daily and spirited driving.

3. Aftermarket Wheels

Perfect for forged and lightweight alloy wheels which benefit from the reduced weight of titanium hardware. Ensures precise fitment and complements premium wheel finishes.

4. Custom Builds and Tuning Projects

Popular among car modification enthusiasts for custom cars, show builds, and tuning upgrades. Titanium’s customizable finishes allow unique styling that stands out at car meets and expos.

5. Supercars and Exotic Vehicles

Trusted by owners of high-end brands such as Ferrari, Lamborghini, Porsche, McLaren, and more. Titanium lug nuts ensure that both performance and durability match the level of these vehicles.

6. Off-Road and Rally Vehicles

Used in demanding off-road conditions where strength, corrosion resistance, and reliability are critical. Titanium’s lightweight nature also benefits vehicles tackling extreme terrain and rapid wheel changes.

7. Brake-Intensive Driving Conditions

Suitable for use in vehicles with high-performance brake systems, where titanium’s heat resistance ensures structural stability even under extreme temperatures caused by repeated hard braking.

|

|

|

|

OEM and Custom Services

Custom thread pitch and seat type

Available in raw titanium or anodized colors

Laser engraved logos or part numbers

Retail-ready packaging with private label

Titanium wheel stud kits available upon request

Modification and customization physical display:

Grooved closed-end automobile wheel nuts:M12x1.5 M12x1.25 M14x1.5 M14x1.25--45mm

|

|

Side hole hollow car wheel nuts:M12x1.5 M14x1.5 M14x1.25--45mm

|

|

|

|

|

Non-slip knurled hollow car wheel nut:M12x1.5 M14x1.5 M14x1.25--45mm

|

|

|

|

|

Hexagon socket wrench for automobile wheel nuts:M12x1.5 M14x1.5 M14x1.25--35/45/50/60mm

|

|

|

|

Eccentric gasket automobile wheel nuts:M12x1.5 M12x1.25 M14x1.5 M14x1.25--35mm

|

|

Ball pad closed hexagon anti-theft car wheel nuts:M12x1.5--35mm

|

|

Spherical gasket closed knurled anti-theft automobile wheel nuts:M12x1.5-48mm

Spherical anti-theft closed-end automobile wheel nuts:M12x1.5-35mm

|

|

Spherical knurled non-moving gasket automobile wheel nut:M12x1.5-35mm

Spherical open automobile wheel nuts:M12x1.5-45mm

|

|

Spherical open semi-hollow automobile wheel nuts:M12x1.5--35mm

|

|

|

|

Spherical open hollow automobile wheel nuts:M12x1.5--35mm

|

|

|

|

Spherical Washer Automobile Wheel Nuts:M12x1.5--45mm

|

|

|

|

Spherical modified car wheel nuts:M14X1.5--45mm

|

|

External plum anti-theft car wheel nuts:M14x1.5 M14x1.25 M12x1.5--35mm

|

|

|

Duckbill ball anti-theft car wheel nut:M14x1.5 M12x1.5 M12x1.25--35mm

|

|

|

Conical hexagonal open automobile wheel nut:M12x1.25--27 37 45mm

|

|

|

|

|

|

Customized according to the following drawings:

Technical Specifications

| Property | Value |

|---|---|

| Tensile Strength | ≥ 895 MPa (Gr5) |

| Yield Strength | ≥ 828 MPa (Gr5) |

| Density | 4.43 g/cm³ |

| Hardness | 36 HRC (Approx.) |

| Thread Tolerance | 6g/6H ISO Metric or UNF/UNC |

| APPLICATION | NUT SEAT TYPE | NUT SIZE | NUT WEIGHT (g) | THREAD PITCH |

|---|---|---|---|---|

| Audi & Volkswagen | R13 Ball (OEM-Style) | 19mm Hex Long | 22.9 | 1.50P |

| Audi & Volkswagen | R13 Ball (OEM-Style) | 19mm Hex Long | 22.9 | 1.50P |

| Audi & Volkswagen | R13 Ball (OEM-Style) | 19mm Hex Long | 22.9 | 1.50P |

| Audi & Volkswagen | R13 Ball (OEM-Style) | 19mm Hex Long | 22.9 | 1.50P |

| Audi & Volkswagen | R13 Ball (OEM-Style) | 19mm Hex Long | 22.9 | 1.50P |

| Audi & Volkswagen | 60° Cone (Aftermarket) | 19mm Hex Long | 22.9 | 1.50P |

| Audi & Volkswagen | 60° Cone (Aftermarket) | 19mm Hex Long | 22.9 | 1.50P |

| Audi & Volkswagen | 60° Cone (Aftermarket) | 19mm Hex Long | 22.9 | 1.50P |

| Audi & Volkswagen | 60° Cone (Aftermarket) | 19mm Hex Long | 22.9 | 1.50P |

| Audi & Volkswagen | 60° Cone (Aftermarket) | 19mm Hex Long | 22.9 | 1.50P |

| BMW & MINI | 60° Cone (OEM-Style) | E24 Torx | 22.9 | 1.50P |

| BMW & MINI | 60° Cone (OEM-Style) | E24 Torx | 22.9 | 1.50P |

| BMW & MINI | 60° Cone (OEM-Style) | E24 Torx | 22.9 | 1.50P |

| BMW & MINI | 60° Cone (OEM-Style) | E24 Torx | 22.9 | 1.50P |

| BMW & MINI | 60° Cone (OEM-Style) | E24 Torx | 22.9 | 1.50P |

Dimensional Capabilities

Thread Sizes: M12,M14, 1/2"-20 UNF

Length Options: 25-60mm, customized sizes available

Seat Type: cone seat、ball seat、tuner、Flat

Type:Ordinary titanium nut、Titanium nut with lock and anti-theft function

|

|

|

|

|

|

|

|

To provide you with an accurate quotation, please kindly fill out the details below and submit the form.

The more complete the information, the faster and more precise our response will be.

Please include the following:

Product Name: __________________________

Dimensions: Inner Diameter _______ × Outer Diameter _______ × height _______

Order Quantity: _______ pcs

Surface Treatment: __________________________

Material: __________________________

Required Delivery Time: __________________________

Shipping Destination: __________________________ (Please include country and postal code)

Drawing File: Please email your design (JPEG, PNG, PDF, or Word format) with a minimum resolution of 300 DPI to ensure clarity.

Contact Details

For more information or to request a quote, feel free to contact us:

- Email:Jolina@bjhyti.com

- Phone: +86-18392721678

Ready to upgrade your wheels with high-quality polished lug nuts? Contact us today to discuss your needs and receive a customized quote!

Product Quality Management

Production and Processing

Workshop and Equipment

Packaging and Delivery

Standard packaging includes foam tray and export carton

Custom retail packaging options available

Lead time is 5 to 10 days for stock sizes and 10 to 20 days for custom sizes

Shipping available via DHL FedEx UPS air freight or sea freight

Global export support with full documentation

Main Products

FAQ

Q1: What is the lifespan of a titanium alloy lug nut?

- Titanium alloy lug nuts are designed for long-term durability, with a lifespan that exceeds conventional steel lug nuts, especially in harsh environments.

Q2: Can I get customized titanium alloy lug nuts?

- Yes, we offer full customization options for sizes, threads, and surface finishes to meet your specific requirements.

Q3: What industries use titanium alloy lug nuts?

- Aerospace, automotive, medical, marine, energy, and chemical processing industries are among the key sectors that rely on titanium alloy lug nuts for their strength, lightweight, and corrosion resistance.

Contact Details

For inquiries or to request a quote, please contact us at:

- Email:Jolina@bjhyti.com

- Phone: +86-18392721678

Get in touch with us today to discuss your specific needs or to learn more about our Factory-Made Titanium Alloy Lug Nuts and how they can benefit your business. We look forward to working with you!

Learn about our latest products and discounts through SMS or email

_1740556039220.webp)

_1739343808027.webp)