- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Titanium Axle Nut for KTM

2.Superior corrosion resistance in extreme environments.

3.Precision threading ensures secure and reliable fastening.

4.High-temperature tolerance for demanding industrial uses.

5.Custom designs available to meet specific requirements.

Titanium Axle Nut for KTM - Product Details Page

Product Introduction

The Titanium Axle Nut for KTM is a high-performance component designed specifically for KTM motorcycles, combining strength, durability, and lightweight properties that are essential for off-road racing and high-performance applications. Manufactured from top-grade titanium alloy, this axle nut offers superior resistance to corrosion, high temperatures, and mechanical stress. Its precision engineering ensures a secure fit, making it a reliable choice for motorcycle enthusiasts and professional racers.

Whether you're upgrading your KTM for a race or simply looking for a long-lasting, high-quality axle nut, this titanium product delivers optimal performance without compromising weight or strength.

Technical Specifications

| Specification | Value |

|---|---|

| Material | Titanium Alloy (Grade 5) |

| Standard | ASTM B348, AMS 4928 |

| Thread Size | M12, M14, M16 |

| Finish | Polished or Anodized |

| Weight | 15-25 grams |

| Torque Strength | 100-150 Nm |

| Temperature Resistance | 400-500°C |

| Corrosion Resistance | Excellent |

| Compatibility | KTM Motorcycles (Multiple Models) |

US Production Grades

- ASTM B348-05: Standard specification for titanium and titanium alloy bars, rods, and billets.

- AMS 4928: Aerospace material specification for titanium alloy.

Russian Production Grades

- TU 14-3-196-94: Titanium alloy for industrial applications.

- GOST 19807-2016: Titanium and titanium alloy bars, rods, and products.

Japanese Production Standards

- JIS H 4652-2007: Titanium and titanium alloy rods, bars, and wire for industrial use.

- JIS T 6110-2004: Titanium alloys for automotive and industrial applications.

|

|

|

|

|

|

|

|

Product Features (Key Features)

- Lightweight: Titanium’s low density ensures that the axle nut adds minimal weight to your KTM, improving performance without compromising strength.

- Corrosion Resistance: The titanium material is highly resistant to saltwater, moisture, and harsh environments, ensuring that the axle nut stays in pristine condition.

- Strength and Durability: Known for its high tensile strength, titanium guarantees the axle nut can withstand the demands of off-road riding, racing, and extreme conditions.

- High Temperature Resistance: Titanium can endure high temperatures, making it ideal for the high-performance environments that KTM motorcycles are subjected to.

- Precision Engineering: Each axle nut is crafted with precision to ensure a perfect fit, preventing any movement or loosening during use.

- Customizable Finish: Available in polished or anodized finishes to suit your aesthetic preferences.

Applications

The Titanium Axle Nut for KTM is designed for use in various high-performance applications, including:

- Motorcycle Racing: Ideal for professional and amateur motocross, supercross, and off-road racing events.

- Custom Builds: A perfect fit for custom-built KTM motorcycles or modifications for those looking to enhance the performance of their bike.

- Endurance Racing: Its durability and resistance to wear make it a top choice for endurance events where reliability is critical.

- Off-Road Riding: Designed for the harsh conditions encountered in off-road riding, providing strength and reliability in rugged environments.

Manufacturing Process

Our Titanium Axle Nuts are produced through a carefully controlled process that ensures top-tier quality and precision. The manufacturing steps include:

- Material Selection: High-grade titanium alloy is sourced from trusted suppliers.

- CNC Machining: Advanced CNC machines are used to cut and shape the axle nut with high precision.

- Anodizing/Polishing: The surface is treated for corrosion resistance and aesthetic appeal.

- Quality Control: Each axle nut undergoes rigorous inspection to ensure it meets ASTM, AMS, and international standards.

Quality Assurance

At Baoji Haiyue New Metal Materials Co., Ltd., quality is our top priority. Our Titanium Axle Nut for KTM is subject to strict quality control at every stage of production. We use advanced testing techniques, including ultrasonic and eddy current testing, to guarantee the strength and reliability of each unit. Every product adheres to international standards and is backed by comprehensive quality certifications.

Packaging and Logistics

The Titanium Axle Nut for KTM is carefully packaged to prevent damage during transport. Each unit is individually wrapped, and bulk orders are securely packed in boxes with appropriate padding. We offer global shipping services, ensuring fast and reliable delivery to regions including North America, Europe, and Asia-Pacific.

Customer Support

We pride ourselves on providing exceptional customer support. Whether you need assistance with product selection, specifications, or post-purchase inquiries, our dedicated support team is here to help. We offer technical consultations, detailed product information, and efficient resolution of any issues.

Why Choose Us

- Complete Product Range: Baoji Haiyue offers a wide range of high-quality titanium products, from axle nuts to bars, plates, and custom components.

- Full-Process Production: We handle every aspect of production, from raw material sourcing to final product delivery, ensuring consistency and quality control.

- One-Stop Solution: With a comprehensive product portfolio and engineering support, we provide customized solutions for all your needs.

- Global Sales and Agency: Our products are distributed worldwide, with a network of partners and distributors in over 20 countries.

- Fast Delivery and Reliable Service: We ensure quick turnaround times and timely deliveries, with a reputation for dependability.

- After-Sales Support: Our customer support team is available to provide assistance post-purchase, including troubleshooting and warranty services.

Development History

Company founded in Baoji, "Titanium Valley," specializing in titanium and non-ferrous metals.

Expanded product range to include zirconium, tantalum, nickel, tungsten, and molybdenum products.

Achieved ISO9001:2015 certification, ensuring high-quality production standards.

Upgraded manufacturing facilities, adding VAR furnaces, CNC machinery, and advanced heat treatment systems.

Expanded global presence, establishing partnerships in the United States, Germany, and South Korea.

Obtained AS9100D certification for aerospace industry compliance and advanced product quality.

Introduced customized solutions for the aerospace, medical, and energy industries, enhancing global reach.

Celebrated 14 years of excellence with over 2,000 tons of annual titanium production capacity.

Product Quality Management

Production and Processing

Workshop and Equipment

Packaging

Main Products

Applied Industries

Be used in a wide range of industries.

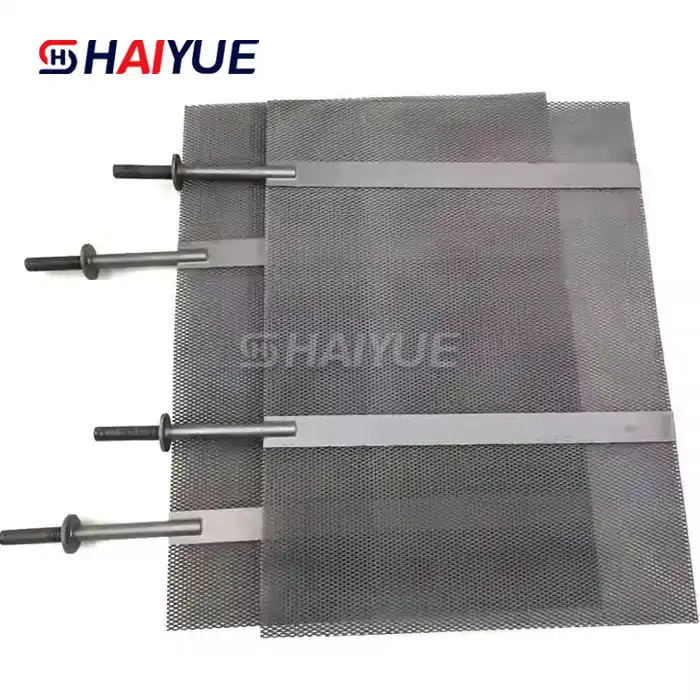

Electrolytic copper foil manufacturing industry

Hydrometallurgy industry

Sewage treatment industry

Cyclone electrolysis industry

Etching liquid electrolysis recovery industry

Electrolytic sodium hypochlorite industry

OEM Services

Baoji Haiyue offers OEM services for the Titanium Axle Nut for KTM, allowing you to customize the product to meet your specific requirements. From custom designs to tailored finishes and sizes, we are capable of meeting the unique needs of Original Equipment Manufacturers (OEMs) in various industries.

Frequently Asked Questions (FAQs)

-

What is the weight of the Titanium Axle Nut for KTM?

- The weight ranges from 15 to 25 grams, depending on the size and specifications.

-

What models of KTM are compatible with this axle nut?

- This axle nut is compatible with multiple KTM motorcycle models. For a specific fit, please consult our product specialists.

-

Is the titanium axle nut corrosion-resistant?

- Yes, titanium is known for its exceptional resistance to corrosion, including saltwater and moisture.

-

Can I get a custom finish on the axle nut?

- Yes, we offer anodized or polished finishes based on your preferences.

-

What are the typical applications for this axle nut?

- The axle nut is perfect for motorcycle racing, custom builds, and off-road or endurance riding.

Contact Details

For quotes, product inquiries, or technical consultations, please feel free to contact us:

- Email:Jolina@bjhyti.com

- Phone Number: +86-18392721678

Get in touch today to learn more about how our Titanium Axle Nut for KTM can enhance your bike’s performance!

Learn about our latest products and discounts through SMS or email

_1739416424977.webp)

_1738823291648.webp)