- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Titanium Shift Knobs For Racing

2.Superior corrosion resistance in extreme environments.

3.Precision threading ensures secure and reliable fastening.

4.High-temperature tolerance for demanding industrial uses.

5.Custom designs available to meet specific requirements.

Titanium Shift Knobs For Racing – High-Performance, Lightweight, and Durable

Product Introduction

Looking for the perfect upgrade for your race car? Our Titanium Shift Knobs for Racing provide the ideal combination of strength, durability, and lightweight performance. Designed for high-performance vehicles, these shift knobs are crafted from premium titanium, ensuring top-tier quality and lasting reliability. Whether you're a professional racer or a car enthusiast, these shift knobs are engineered to enhance your driving experience and give you an edge on the track.

Technical Specifications

Our Titanium Shift Knobs for Racing come with a detailed set of specifications tailored to meet the high demands of the racing industry. Below are the technical details that define their exceptional performance:

Titanium Shift Knob Specifications

| Attribute | Details |

|---|---|

| Material | Grade 5 Titanium (Ti-6Al-4V) |

| Weight | 130g (Approx.) |

| Thread Size | M8x1.25, M10x1.5, M12x1.75 (Custom options available) |

| Finish | Polished, Matte, Anodized |

| Height | 60mm-100mm (Customizable) |

| Hardness | 38 HRC |

| Operating Temperature | -50°C to 300°C |

| Surface Treatment | High-temperature anodizing for enhanced wear resistance |

| Compliance | ASTM B265, AMS 4928 |

Production Grades and Standards

| Region | Grade/Standard |

|---|---|

| United States | ASTM B265, AMS 4928 |

| Russia | TU 48-19-1-94 (Titanium alloy standard) |

| Japan | JIS H 4620 |

Performance Testing

| Test Type | Method | Standard |

|---|---|---|

| Tensile Strength | ASTM E8 | 900 MPa (Minimum) |

| Hardness Test | Rockwell B Scale | 35-45 HRC |

| Corrosion Resistance | Salt Spray Test | ASTM B117 (1000 hours) |

|

|

|

|

|

|

|

|

Product Features (Key Features)

- Lightweight & Durable: Crafted from high-quality Grade 5 titanium, these shift knobs provide a perfect balance of lightweight performance and long-lasting durability, essential for racing environments.

- Precision Engineering: Every shift knob is CNC-machined for precise sizing and fitment, ensuring smooth and reliable shifting during high-speed maneuvers.

- Corrosion Resistance: Titanium is naturally corrosion-resistant, making it ideal for harsh racing conditions, ensuring your shift knob stays in top condition for years.

- Customizable Options: Available in a variety of thread sizes, finishes, and designs to suit your specific vehicle and aesthetic preferences.

- Heat Resistance: Titanium’s ability to withstand extreme temperatures ensures it performs reliably even in the most demanding race environments.

Applications

Our Titanium Shift Knobs for Racing are perfect for a variety of high-performance applications:

- Racing Cars: Enhance the control and precision of your gear shifting for a smoother, faster driving experience.

- Motorcycles: Ideal for high-speed bike enthusiasts seeking a lightweight yet durable shift knob.

- Custom Builds: Perfect for custom car builds and tuning projects, where performance and aesthetics are key.

- Off-Road Vehicles: Designed to withstand the roughest terrains and extreme temperatures while maintaining peak performance.

Manufacturing Process

Our shift knobs are manufactured using advanced precision CNC machining processes, ensuring each unit is made to exact specifications. The raw titanium is sourced from reputable suppliers, undergoes strict quality control checks, and is processed in high-tech facilities equipped with cutting-edge machinery. After machining, the shift knobs undergo a thorough anodizing process, which enhances their surface durability and provides a high-quality finish.

Quality Assurance

At Baoji Haiyue New Metal Materials Co., Ltd., quality is paramount. Our Titanium Shift Knobs undergo multiple quality assurance checks during every stage of production, from raw material inspection to the final product inspection. Testing methods include tensile strength, hardness, and corrosion resistance to ensure our products meet the highest industry standards.

We are ISO9001:2015 certified, ensuring that our manufacturing processes are consistently controlled to deliver superior products with unmatched quality.

Packaging and Logistics

We understand the importance of safe and timely delivery. Our Titanium Shift Knobs for Racing are packaged securely in durable boxes to prevent any damage during transit. We offer flexible shipping options and can deliver globally, ensuring your order reaches you quickly, no matter your location. We provide both air and sea freight solutions, depending on your needs.

Customer Support

Our customer support team is always ready to assist you with any inquiries. Whether you need help with choosing the right shift knob for your vehicle or require assistance with custom orders, our team of experts is here to ensure your satisfaction. We provide technical support and after-sales service to make sure your experience with us is seamless.

Why Choose Us?

- Complete Product Range: We offer a wide variety of high-quality titanium products, including shift knobs, bars, plates, and more, ensuring you get everything you need from a single trusted supplier.

- Fast Delivery: With efficient production and global shipping, we guarantee timely delivery to meet your project deadlines.

- Global Sales & Agency: Our products are trusted worldwide, and we work with clients from over 20 countries, providing the best solutions for various industries.

- Customized Products: We offer full customization options for sizes, finishes, and thread types to meet your specific requirements.

- Competitive Pricing: Get the best value without compromising on quality.

Development History

Company founded in Baoji, "Titanium Valley," specializing in titanium and non-ferrous metals.

Expanded product range to include zirconium, tantalum, nickel, tungsten, and molybdenum products.

Achieved ISO9001:2015 certification, ensuring high-quality production standards.

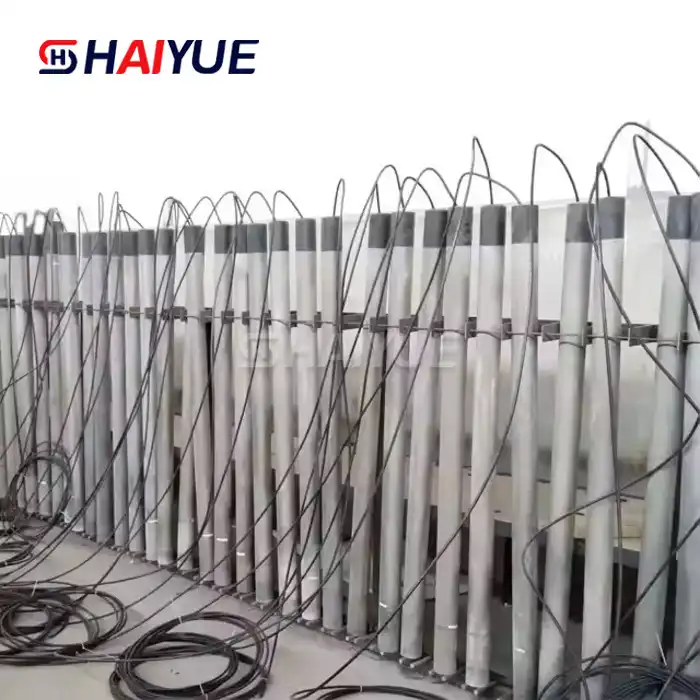

Upgraded manufacturing facilities, adding VAR furnaces, CNC machinery, and advanced heat treatment systems.

Expanded global presence, establishing partnerships in the United States, Germany, and South Korea.

Obtained AS9100D certification for aerospace industry compliance and advanced product quality.

Introduced customized solutions for the aerospace, medical, and energy industries, enhancing global reach.

Celebrated 14 years of excellence with over 2,000 tons of annual titanium production capacity.

Product Quality Management

Production and Processing

Workshop and Equipment

Packaging

Main Products

Applied Industries

Be used in a wide range of industries.

Electrolytic copper foil manufacturing industry

Hydrometallurgy industry

Sewage treatment industry

Cyclone electrolysis industry

Etching liquid electrolysis recovery industry

Electrolytic sodium hypochlorite industry

OEM Services

We also offer OEM services to customers who require customized designs and solutions. Our experienced engineers can work with you to create titanium shift knobs tailored to your specifications, ensuring the perfect fit for your needs.

Frequently Asked Questions (FAQs)

Q1: Are the titanium shift knobs compatible with all vehicles? Yes, we offer a range of thread sizes to ensure compatibility with most vehicles. If you're unsure about the fitment, our team is happy to assist you.

Q2: Can I customize the finish of the shift knob? Absolutely! We offer polished, matte, and anodized finishes, and we can even create custom designs upon request.

Q3: How long does it take to receive my order? Delivery time depends on your location. Typically, it takes 7-15 days for international shipping. Expedited options are available.

Q4: Are the shift knobs available for bulk purchase? Yes, we offer bulk purchasing options for larger orders, and we can provide discounted rates for wholesale buyers.

Contact Details

For more information or to request a quote, please feel free to contact us:

Email:Jolina@bjhyti.com

Phone: +86-18392721678

Get in touch today to upgrade your vehicle with the best Titanium Shift Knobs for Racing!

Learn about our latest products and discounts through SMS or email

_1738829145038.webp)

_1740469357015.webp)