- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

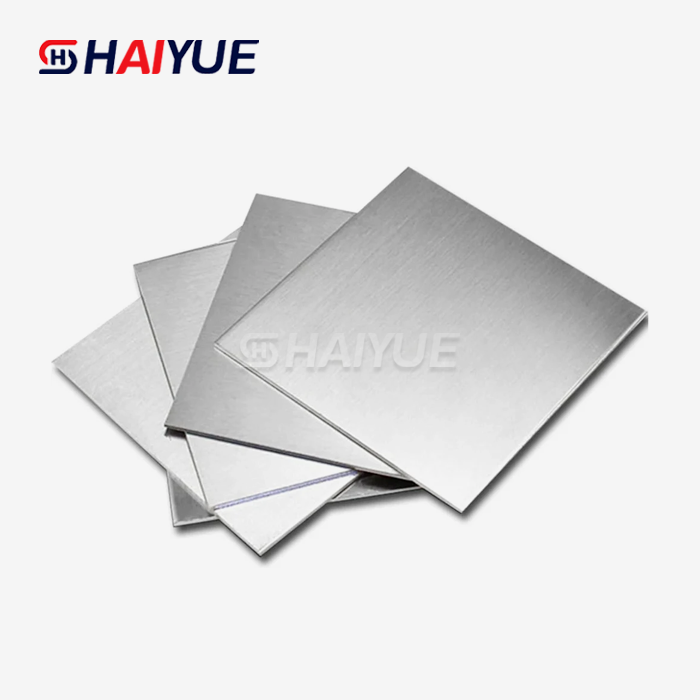

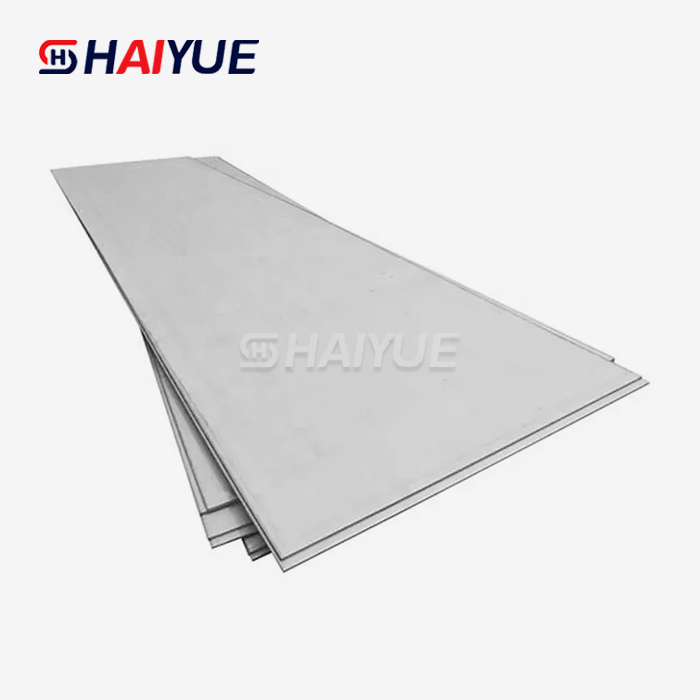

titanium grade 5 plate 25x4x4

2.Lightweight design, perfect for aerospace and marine industries.

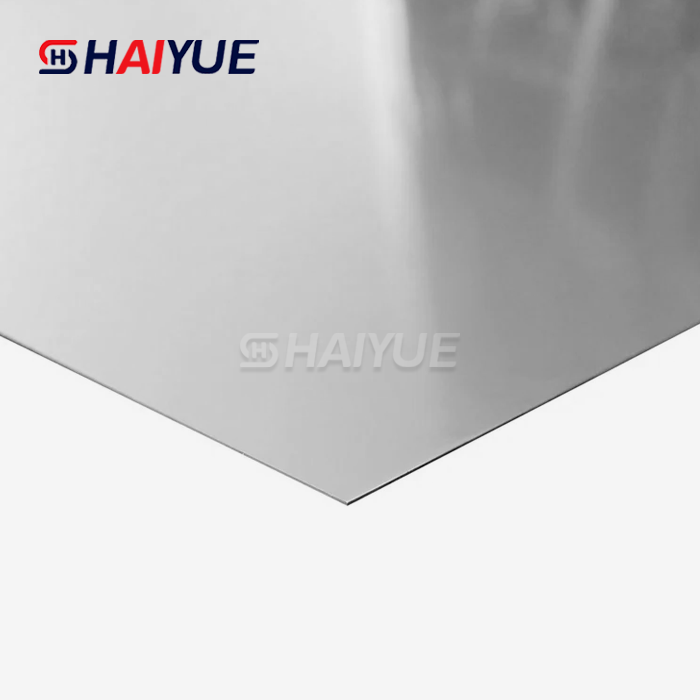

3.Superior surface finish for reliable industrial applications.

4.Excellent weldability and formability for custom projects.

5.Precision thickness control ensures consistent performance.

Titanium Grade 5 Plate 25x4x4 – High-Performance Material for Critical Applications

Product Introduction

Titanium Grade 5, also known as Ti-6Al-4V, is one of the most widely used titanium alloys, known for its excellent combination of strength, light weight, and corrosion resistance. The Titanium Grade 5 Plate 25x4x4, with dimensions of 25mm thickness, 4mm width, and 4mm length, is a prime choice for industries requiring superior material performance, such as aerospace, medical, and energy sectors.

Whether you are an OEM in aerospace, a medical device manufacturer, or an industrial fabricator, our Titanium Grade 5 Plate 25x4x4 offers unparalleled reliability, durability, and versatility, making it the ideal solution for high-demand applications. Baoji Haiyue New Metal Materials Co., Ltd. is proud to provide this high-quality titanium product, tailored to meet the specific needs of various industries worldwide.

Technical Specifications

| Property | Value | Unit | Standard |

|---|---|---|---|

| Alloy | Titanium Grade 5 (Ti-6Al-4V) | - | ASTM B348, AMS 492 |

| Density | 4.43 | g/cm³ | ASTM B348 |

| Tensile Strength | 900-1,200 | MPa | ASTM B348 |

| Yield Strength | 880-1,100 | MPa | ASTM B348 |

| Elongation | 10-15 | % | ASTM B348 |

| Hardness | 330-400 | HV | ASTM B348 |

| Modulus of Elasticity | 110-120 | GPa | ASTM B348 |

| Thermal Conductivity | 7.0-8.0 | W/m·K | ASTM B348 |

| Melting Point | 1,660 | °C | ASTM B348 |

| Corrosion Resistance | Excellent in chloride-rich environments | - | ASTM G48 |

| Dimensions | 25x4x4 | mm | - |

Production Standards:

- United States (ASTM B348): Specifications for titanium and titanium alloy bars and billets.

- Russia (GOST 19807-74): Titanium and its alloys for aerospace applications.

- Japan (JIS H 4625): Titanium alloy plates, bars, and rods for industrial use.

|

|

|

|

|

|

|

|

Key Features

- High Strength-to-Weight Ratio: Titanium Grade 5 is renowned for its superior strength while being significantly lighter than most steels and alloys, making it ideal for lightweight applications in the aerospace and medical sectors.

- Excellent Corrosion Resistance: This material is highly resistant to corrosion, including in harsh environments such as seawater and chemical processing applications.

- Versatility: Titanium Grade 5 can be used in a wide range of applications, from structural components to high-performance medical implants.

- Non-Magnetic and Biocompatible: Non-reactive with the human body, ensuring safe use in medical devices and implants.

- Easy Machinability: Despite its high strength, Titanium Grade 5 is easier to machine compared to other titanium alloys, providing flexibility for custom machining.

Applications

Titanium Grade 5 Plate 25x4x4 is versatile and used in industries demanding high-performance materials, including:

- Aerospace: Aircraft and spacecraft components such as turbine blades, engine parts, and landing gear.

- Medical Devices: Biocompatible implants, surgical instruments, and prosthetics.

- Chemical Processing: Reactors, pipes, and heat exchangers in corrosive environments.

- Energy: Components for nuclear power plants, wind turbines, and solar applications.

- Marine Engineering: Offshore structures, shipbuilding, and seawater-resistant applications.

- Industrial Manufacturing: Durable tools, fasteners, and structural components.

Manufacturing Process

Our Titanium Grade 5 Plate 25x4x4 is manufactured using state-of-the-art equipment and processes to ensure consistency, quality, and precision. The process includes:

- Raw Material Selection: We source only high-grade titanium alloys from certified suppliers to ensure top-notch raw material quality.

- Casting and Forging: The titanium alloy is melted and formed into the desired shape through advanced forging processes, ensuring high uniformity and minimized defects.

- Rolling and Milling: The titanium plates are rolled and milled to precise thickness, width, and length specifications.

- Heat Treatment: To enhance mechanical properties, the material undergoes controlled heat treatment processes.

- Surface Finishing: We apply surface treatments to optimize corrosion resistance and mechanical performance.

- Final Inspection: Each plate is rigorously inspected for quality, including dimensional checks, hardness testing, and visual inspection.

Quality Assurance

At Baoji Haiyue, quality is our top priority. Our Titanium Grade 5 Plate 25x4x4 undergoes strict quality control measures at every stage of production:

- Material Testing: We perform extensive tests, including tensile, hardness, and chemical composition analysis.

- Certifications: Our products meet international standards, including ISO9001:2015, AS9100D, and GJB9001C:2007, ensuring compliance with aerospace, medical, and industrial requirements.

- Third-Party Inspections: We regularly work with third-party inspectors to verify that all products meet the highest standards.

- Traceability: Every batch of material is fully traceable, ensuring that our customers receive the exact product they ordered.

Packaging and Logistics

We understand the importance of safe and timely delivery. Our Titanium Grade 5 Plates are carefully packaged to prevent damage during transportation:

- Packaging: Plates are wrapped in protective plastic or foam and securely packed in wooden crates or metal boxes.

- Logistics: We offer fast, reliable shipping options, ensuring that your order reaches you on time. Global delivery services are available for customers in North America, Europe, and Asia.

Customer Support

Our dedicated customer support team is here to assist you at every step of the process. From providing detailed product specifications to offering technical guidance, we ensure that you have all the information you need to make informed decisions.

- Technical Assistance: Our engineers are available to help with material selection, customization options, and application advice.

- Order Tracking: You can easily track your order to stay updated on delivery timelines.

Why Choose Baoji Haiyue?

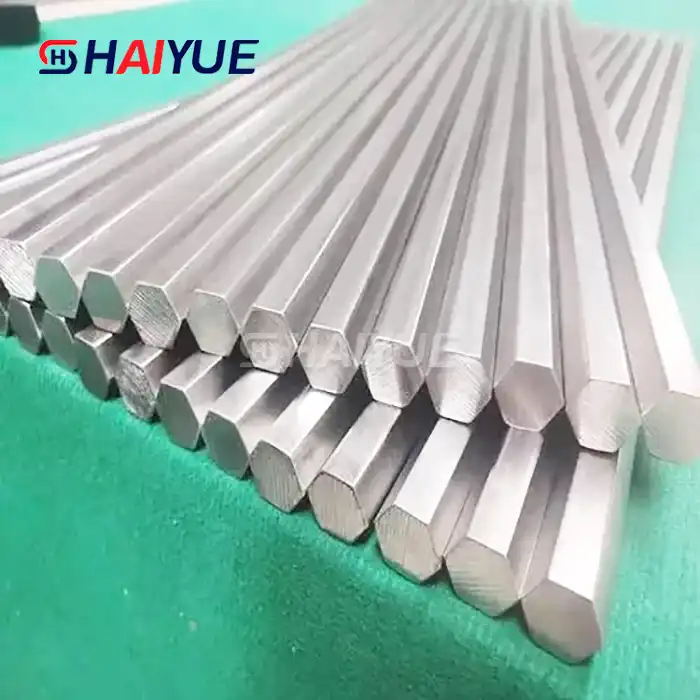

- Complete Product Range: We offer a full range of titanium products, including bars, plates, tubes, and custom CNC-machined components.

- Full-Process Production: From raw material selection to final product inspection, we handle every step of the manufacturing process in-house.

- Global Reach: Serving customers in over 20 countries with fast, reliable international shipping.

- Custom Solutions: We offer tailored sizes, shapes, and alloy grades to meet your specific needs.

- Fast Delivery & Timely After-Sales Service: We ensure that your order is delivered promptly, with a focus on providing timely after-sales support.

Development History

Company founded in Baoji, "Titanium Valley," specializing in titanium and non-ferrous metals.

Expanded product range to include zirconium, tantalum, nickel, tungsten, and molybdenum products.

Achieved ISO9001:2015 certification, ensuring high-quality production standards.

Upgraded manufacturing facilities, adding VAR furnaces, CNC machinery, and advanced heat treatment systems.

Expanded global presence, establishing partnerships in the United States, Germany, and South Korea.

Obtained AS9100D certification for aerospace industry compliance and advanced product quality.

Introduced customized solutions for the aerospace, medical, and energy industries, enhancing global reach.

Celebrated 14 years of excellence with over 2,000 tons of annual titanium production capacity.

Product Quality Management

Production and Processing

Workshop and Equipment

Packaging

Main Products

Applied Industries

Be used in a wide range of industries.

Electrolytic copper foil manufacturing industry

Hydrometallurgy industry

Sewage treatment industry

Cyclone electrolysis industry

Etching liquid electrolysis recovery industry

Electrolytic sodium hypochlorite industry

OEM Services

Baoji Haiyue offers comprehensive OEM services, ensuring that you receive customized titanium solutions that meet your specific requirements. Whether you need custom sizes, alloy variations, or specific processing treatments, we can accommodate your needs with precision.

Frequently Asked Questions (FAQs)

1. What industries use Titanium Grade 5 Plate?

Titanium Grade 5 Plate is used in aerospace, medical devices, chemical processing, energy, marine engineering, and industrial manufacturing industries.

2. What are the standard certifications for Titanium Grade 5 Plate?

Our Titanium Grade 5 Plates meet ISO9001:2015, AS9100D, and GJB9001C:2007 certifications.

3. Can I get a custom size or shape?

Yes, we provide custom CNC machining services to meet your exact specifications.

4. How is the product packaged for shipping?

The plates are carefully wrapped in protective plastic or foam and packed in secure crates or boxes.

Contact Us

For more information or a customized quote, please contact us directly:

- Email:Jolina@bjhyti.com

- Phone: +86-18392721678

Learn about our latest products and discounts through SMS or email

_1736491578675.webp)

_1742177138212.webp)