- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Blind Titanium flange

2.Lightweight and strong for efficient piping connections.

3.Precision-machined for excellent sealing performance.

4.High-temperature tolerance for industrial applications.

5.Custom sizes and standards to fit specific requirements.

Blind Titanium Flange: Your Ultimate Choice for High-Performance Applications

Product Introduction

A [Blind Titanium Flange] is an essential component in various industrial applications, designed to close off the ends of pipelines, valves, and pressure vessels. Engineered from premium titanium, it offers unparalleled strength, lightweight properties, and exceptional resistance to corrosion and high temperatures. These flanges are indispensable in industries demanding high reliability, such as aerospace, medical devices, and chemical processing.

Technical Specifications

Below is a detailed technical breakdown of the specifications for [Blind Titanium Flange]:

General Specifications:

| Property | Value |

|---|---|

| Material | Titanium (Grade 2, Grade 5) |

| Manufacturing Standard | ASTM B381, ASME B16.5, JIS B2220 |

| Size Range | 1/2" to 48" |

| Pressure Rating | Class 150 to Class 2500 |

| Surface Finish | Smooth, serrated, or custom |

Production Grades and Standards:

| Country | Grades | Standards |

| United States | Grade 2, Grade 5 | ASTM B381 |

| Russia | BT1-0, BT6 | GOST 19807-91 |

| Japan | Ti-2, Ti-6Al-4V | JIS H4600 |

Dimensional Standards:

| Parameter | Range |

| Outer Diameter (OD) | 20 mm - 1200 mm |

| Thickness | 3 mm - 150 mm |

| Bolt Circle Diameter | As per standards |

|

|

|

|

|

|

|

|

Product Features

Key features of the [Blind Titanium Flange] include:

-

High Strength-to-Weight Ratio: Ensures robust performance without adding unnecessary weight.

-

Corrosion Resistance: Exceptional resistance to harsh chemicals and marine environments.

-

Thermal Stability: Performs reliably at both high and low temperatures.

-

Customization: Available in a range of sizes, finishes, and pressure ratings to meet diverse requirements.

Applications

The [Blind Titanium Flange] is widely used across various industries:

-

Aerospace: Ideal for aircraft engine components and structural elements.

-

Medical Devices: Used in biocompatible equipment like surgical tools and implants.

-

Chemical Processing: Handles aggressive chemicals in reactors and storage tanks.

-

Energy Sector: Essential in nuclear reactors and renewable energy systems.

-

Marine Engineering: Resists saltwater corrosion for offshore and shipbuilding projects.

-

Industrial Manufacturing: Utilized in heavy machinery and tools.

Manufacturing Process

-

Raw Material Selection: Premium titanium sourced and inspected for purity.

-

Forging: Flanges are forged to shape using advanced equipment.

-

Machining: CNC machines ensure precise dimensions and a smooth finish.

-

Heat Treatment: Enhances mechanical properties and durability.

-

Surface Finishing: Options include polished, sandblasted, or custom finishes.

-

Inspection and Testing: Rigorous quality checks ensure compliance with standards.

Quality Assurance

Baoji Haiyue adheres to stringent quality control processes:

-

Certifications: ISO9001:2015, AS9100D, GJB9001C:2007.

-

Advanced Testing: Ultrasonic, eddy current, and spectral analysis.

-

Inspection Stages: From raw material validation to final product evaluation.

Packaging and Logistics

Our [Blind Titanium Flange] products are meticulously packed to ensure safe transit:

-

Packaging Materials: Wooden crates, bubble wrap, and moisture-proof coverings.

-

Global Shipping: Reliable and timely delivery to over 20 countries.

-

Custom Solutions: Packaging tailored to specific customer needs.

Customer Support

We prioritize customer satisfaction by offering:

-

Expert consultation on material selection.

-

Responsive support via email, phone, and online platforms.

-

Door-to-door service for seamless procurement.

Why Choose Us

-

Complete Product Range: Extensive portfolio covering all titanium and non-ferrous metal needs.

-

Full-Process Production: In-house manufacturing for superior quality control.

-

Global Reach: Trusted by customers in over 20 countries.

-

Fast Delivery: Efficient logistics ensure timely delivery.

-

Custom Solutions: Tailored products to meet unique specifications.

-

Exceptional Service: Comprehensive after-sales support.

Development History

Company founded in Baoji, "Titanium Valley," specializing in titanium and non-ferrous metals.

Expanded product range to include zirconium, tantalum, nickel, tungsten, and molybdenum products.

Achieved ISO9001:2015 certification, ensuring high-quality production standards.

Upgraded manufacturing facilities, adding VAR furnaces, CNC machinery, and advanced heat treatment systems.

Expanded global presence, establishing partnerships in the United States, Germany, and South Korea.

Obtained AS9100D certification for aerospace industry compliance and advanced product quality.

Introduced customized solutions for the aerospace, medical, and energy industries, enhancing global reach.

Celebrated 14 years of excellence with over 2,000 tons of annual titanium production capacity.

Product Quality Management

Production and Processing

Workshop and Equipment

Packaging

Main Products

Applied Industries

Be used in a wide range of industries.

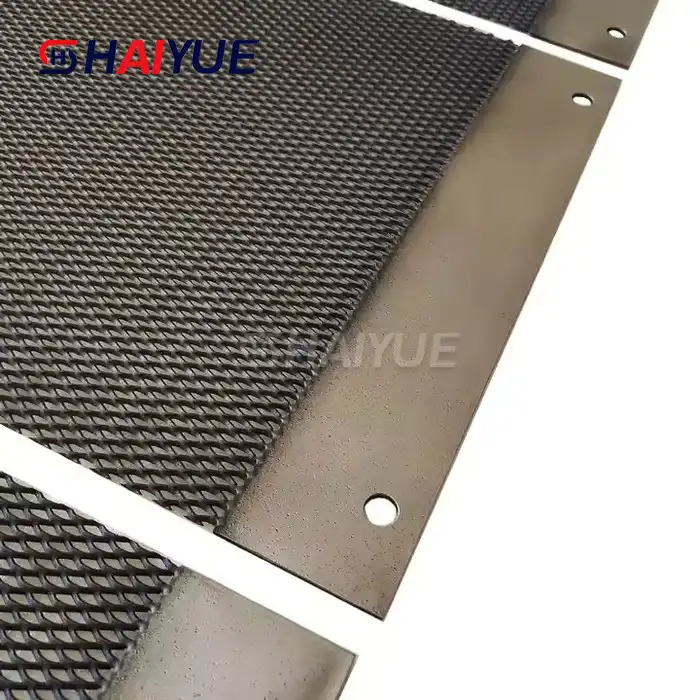

Electrolytic copper foil manufacturing industry

Hydrometallurgy industry

Sewage treatment industry

Cyclone electrolysis industry

Etching liquid electrolysis recovery industry

Electrolytic sodium hypochlorite industry

OEM Services

We specialize in providing OEM solutions for customized [Blind Titanium Flange] products:

-

Custom dimensions and specifications.

-

Branding and labeling as per client requirements.

-

Collaboration with design and engineering teams.

Frequently Asked Questions (FAQs)

Q: What are the key advantages of titanium blind flanges over steel?

A: Titanium blind flanges offer superior corrosion resistance, lighter weight, and better thermal stability than steel alternatives.

Q: Can you provide customized dimensions?

A: Yes, we offer fully customized dimensions and specifications to meet your needs.

Q: What certifications do your products have?

A: Our products are certified under ISO9001:2015, AS9100D, and GJB9001C:2007 standards.

Q: Do you ship internationally?

A: Yes, we provide reliable global shipping to over 20 countries.

Contact Details

For inquiries, quotes, or more information, contact us:

-

Email:Jolina@bjhyti.com

-

Phone: +86-18392721678

Get in touch today to experience the quality and reliability of Baoji Haiyue’s [Blind Titanium Flange]!

Learn about our latest products and discounts through SMS or email

(1)_1739177231924.webp)

_1750228251491.webp)