- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

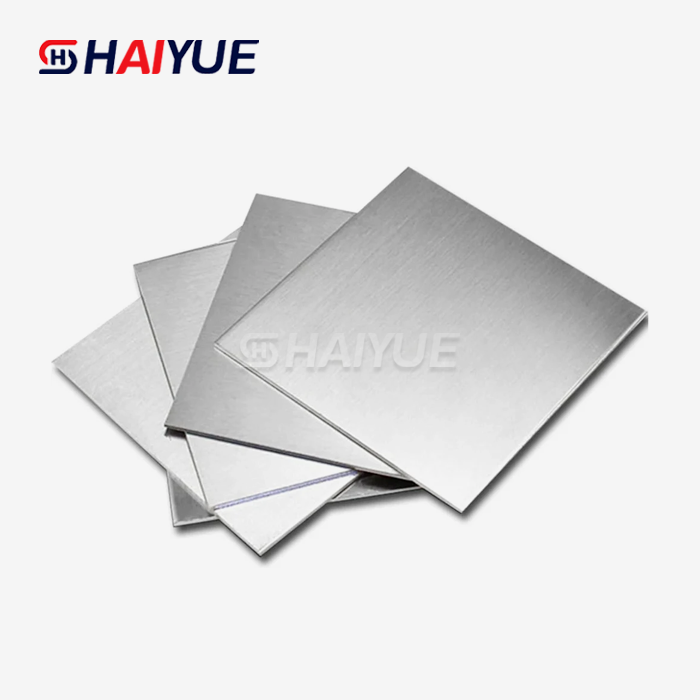

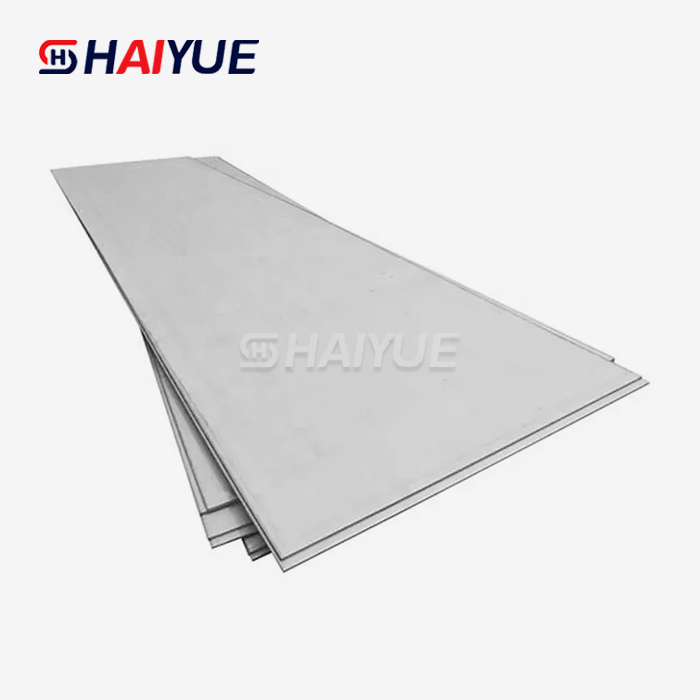

Medical Grade Titanium Alloy Plate

2.Lightweight design, perfect for aerospace and marine industries.

3.Superior surface finish for reliable industrial applications.

4.Excellent weldability and formability for custom projects.

5.Precision thickness control ensures consistent performance.

Medical Grade Titanium Alloy Plate

Product Introduction

Medical Grade Titanium Alloy Plate is a high-performance material designed to meet the strict demands of the medical industry. Known for its excellent biocompatibility, corrosion resistance, and high strength-to-weight ratio, titanium alloy plates are widely used in critical medical applications such as implants, prosthetics, surgical instruments, and dental devices.

Titanium’s natural resistance to bodily fluids and its ability to bond with bone tissue make it the material of choice for orthopedic implants, dental crowns, and pacemaker casings. With superior mechanical properties and an ability to withstand the harsh conditions of the human body, medical grade titanium alloy plates ensure long-term durability and patient safety.

Technical Specifications

The following table outlines the key specifications for Medical Grade Titanium Alloy Plates. These plates conform to international standards and are available in various grades, offering excellent versatility for a wide range of medical applications.

Titanium Alloy Grades and Standards

| Grade | Titanium Alloy | Main Composition | Key Standard | Typical Uses |

|---|---|---|---|---|

| Grade 5 | Ti-6Al-4V | 90% Titanium, 6% Aluminum, 4% Vanadium | ASTM F136, ISO 5832-3, AMS 4928 | Orthopedic Implants, Surgical Tools |

| Grade 23 | Ti-6Al-4V ELI | 90% Titanium, 6% Aluminum, 4% Vanadium | ASTM F136, ISO 5832-3, AMS 4931 | Dental Implants, Bone Screws |

| Grade 2 | Commercially Pure Ti | 99% Titanium | ASTM F67, ISO 5832-2, AMS 4911 | Surgical Instruments, Fasteners |

Medical Grade Titanium Alloy Plate Dimensions

| Thickness (mm) | Width (mm) | Length (mm) | Weight (kg/m²) |

|---|---|---|---|

| 0.5 | 200 | 1000 | 1.5 |

| 1.0 | 250 | 2000 | 2.8 |

| 2.0 | 300 | 3000 | 5.5 |

| 5.0 | 350 | 4000 | 13.5 |

Mechanical Properties of Medical Grade Titanium Alloy Plates

| Property | Grade 5 | Grade 23 | Grade 2 |

|---|---|---|---|

| Tensile Strength | 900 MPa | 860 MPa | 275 MPa |

| Yield Strength | 830 MPa | 790 MPa | 240 MPa |

| Elongation | 10% | 10% | 20% |

| Hardness | 36 HRC | 34 HRC | 32 HRC |

|

|

|

|

|

|

|

|

Product Features (Key Features)

- Biocompatible: Titanium is known for its compatibility with human tissue, minimizing the risk of rejection or infection in medical applications.

- Corrosion-Resistant: The natural oxide layer on titanium makes it highly resistant to corrosion, even in aggressive environments such as bodily fluids.

- Lightweight and Strong: Titanium alloys are known for their high strength-to-weight ratio, ensuring reliability without adding excess weight to medical devices.

- Non-Toxic: Medical-grade titanium does not release harmful substances into the body, making it a safe choice for implants and prosthetics.

- Fatigue Resistant: Titanium alloy plates withstand cyclic loading, which is crucial for implants subjected to repeated body movements.

- Customizable: Plates can be tailored to specific medical needs, with options for different sizes, shapes, and grades of titanium.

Applications

- Orthopedic Implants: Used for joint replacements, bone fixation plates, and spinal implants.

- Dental Implants: Titanium alloy plates are utilized in dental crowns, bridges, and implants for their strength and biocompatibility.

- Surgical Tools: Titanium is used to manufacture scalpels, forceps, and surgical scissors, where corrosion resistance and strength are essential.

- Prosthetics: Prosthetic limbs, especially those with titanium components, benefit from the material’s strength and lightweight properties.

- Medical Equipment: Used in a variety of other medical devices, including pacemakers, hearing aids, and surgical instruments.

Manufacturing Process

The production of Medical Grade Titanium Alloy Plates involves several critical steps to ensure top-tier quality and consistency:

- Titanium Extraction: The process begins with extracting titanium from its ores, primarily rutile or ilmenite.

- Alloying: Titanium is then alloyed with elements like aluminum and vanadium (for Grade 5) to achieve the desired properties.

- Forging & Rolling: The material is forged and rolled into plates using advanced machinery to meet specific thickness and dimension requirements.

- Heat Treatment: Plates undergo heat treatment processes to improve mechanical properties, including strength and hardness.

- Surface Finishing: The final product is polished or coated to ensure a smooth finish and enhance biocompatibility.

Quality Assurance

At Baoji Haiyue New Metal Materials Co., Ltd., we adhere to the highest standards of quality control:

- ISO 9001:2015: Our processes are certified to ensure consistency and quality throughout production.

- Spectral Analysis: Every batch of titanium alloy is tested for composition to guarantee it meets medical-grade standards.

- Ultrasonic and Eddy Current Testing: These advanced testing techniques help detect internal and surface defects, ensuring the integrity of every plate.

- Mechanical Property Testing: Tensile and hardness tests ensure that the material meets stringent medical requirements for strength and durability.

Packaging and Logistics

- Packaging: Plates are carefully packed in moisture-resistant and shockproof materials to prevent damage during transit.

- Logistics: We offer fast and reliable delivery worldwide through trusted logistics partners. Customized shipping options are available to meet client preferences.

Customer Support

Our dedicated customer support team is always available to assist you with any inquiries. Whether you need product information, technical advice, or order status updates, we are here to help.

Why Choose Us?

- Complete Product Range: We offer a comprehensive range of medical-grade titanium alloys and other non-ferrous metal products.

- Full-Process Production: From raw material procurement to final delivery, we control the entire production process to ensure quality at every step.

- Customized Products: We provide tailored solutions, including custom sizes and specifications, to meet unique customer needs.

- Global Sales and Agency: With a global presence, we serve customers across North America, Europe, Asia, and beyond.

- Timely After-Sales Service: Our dedicated after-sales support team ensures you receive timely assistance whenever needed.

- Fast Delivery: We prioritize fast and reliable delivery, ensuring your production schedule remains on track.

OEM Services

Baoji Haiyue offers OEM services for clients who require specific products or custom solutions. We work closely with you to develop and supply the exact materials and products needed for your medical or industrial applications.

Frequently Asked Questions (FAQs)

Q: What grades of titanium alloy are available for medical use?

A: We offer several grades, including Grade 5 (Ti-6Al-4V), Grade 23 (Ti-6Al-4V ELI), and Grade 2 (Commercially Pure Titanium). Each has unique properties suited to specific applications.

Q: Is the titanium alloy used in medical devices certified?

A: Yes, our titanium alloys meet international medical standards such as ASTM, ISO, and AMS certifications.

Q: Can I get a custom size or shape for my titanium plate?

A: Yes, we offer customizable products based on your specific requirements.

Q: How do I ensure the quality of the titanium plates I am purchasing?

A: We conduct extensive quality control measures, including material testing, dimensional inspections, and mechanical property evaluations.

Contact Details

For quotes or more information, feel free to reach out to us:

- Email:Jolina@bjhyti.com

- Phone: +86-18392721678

Development History

Company founded in Baoji, "Titanium Valley," specializing in titanium and non-ferrous metals.

Expanded product range to include zirconium, tantalum, nickel, tungsten, and molybdenum products.

Achieved ISO9001:2015 certification, ensuring high-quality production standards.

Upgraded manufacturing facilities, adding VAR furnaces, CNC machinery, and advanced heat treatment systems.

Expanded global presence, establishing partnerships in the United States, Germany, and South Korea.

Obtained AS9100D certification for aerospace industry compliance and advanced product quality.

Introduced customized solutions for the aerospace, medical, and energy industries, enhancing global reach.

Celebrated 14 years of excellence with over 2,000 tons of annual titanium production capacity.

Product Quality Management

Production and Processing

Workshop and Equipment

Packaging

Main Products

Applied Industries

Be used in a wide range of industries.

Electrolytic copper foil manufacturing industry

Hydrometallurgy industry

Sewage treatment industry

Cyclone electrolysis industry

Etching liquid electrolysis recovery industry

Electrolytic sodium hypochlorite industry

Learn about our latest products and discounts through SMS or email

_1736480174749.webp)

_1739241663280.webp)

_1739866215240.webp)