Understanding Titanium Wheel Axle Nuts

Titanium wheel pivot nuts are a well-known choice among car devotees and proficient mechanics for a few reasons. These nuts are designed to secure the wheel to the pivot, guaranteeing a secure and steady ride. But what sets titanium apart from other materials?

The Properties of Titanium

Titanium is eminent for its uncommon strength-to-weight proportion. It's as solid as steel but 45% lighter, making it a perfect fabric for car applications where weight diminishment is vital. Additionally, titanium brags amazing erosion resistance, which is a key calculate when considering whether these nuts will rust.

Advantages of Titanium Wheel Axle Nuts

The use of titanium wheel axle nuts offers several benefits:

- Lightweight: Reduces unsprung weight, potentially improving vehicle performance

- Durability: Withstands high stress and repeated use

- Corrosion resistance: Highly resistant to rust and other forms of corrosion

- Temperature stability: Maintains integrity across a wide range of temperatures

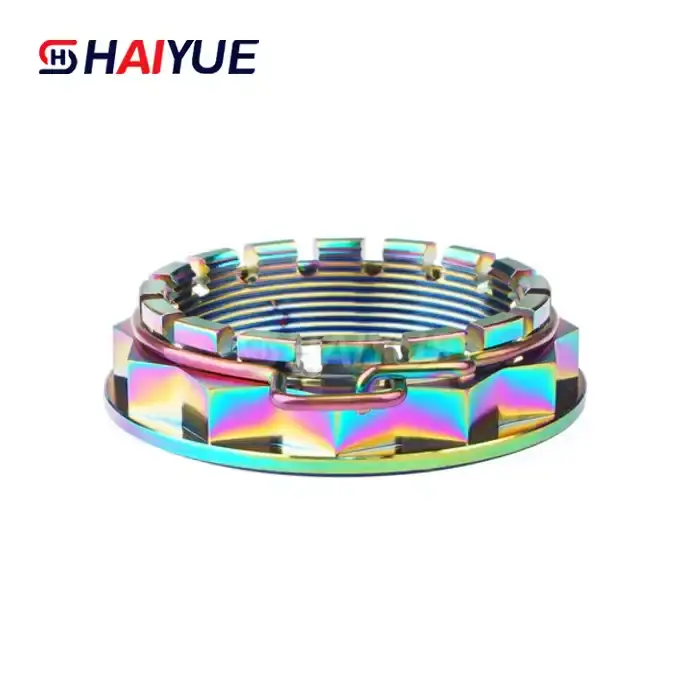

- Aesthetic appeal: Often features a sleek, modern look

The Rust Resistance of Titanium Axle Nuts

Now, let's address the main question: Will titanium axle nuts rust? The short answer is no, titanium axle nuts are highly resistant to rust. Here's why:

Titanium's Natural Oxide Layer

Titanium shapes a common oxide layer when uncovered to discuss. This minuscule layer acts as a defensive obstruction, anticipating advanced oxidation and erosion. Not at all like press or steel, which form rust (press oxide) that proceeds to eat away at the metal, titanium's oxide layer is steady and self-healing.

Comparing Titanium to Other Materials

To better understand titanium's rust resistance, let's compare it to other common materials used for axle nuts:

- Steel: Prone to rust, especially in humid or salty environments

- Stainless Steel: Better rust resistance than regular steel, but still susceptible in harsh conditions

- Aluminum: Resistant to rust but can corrode in certain environments

- Titanium: Highly resistant to rust and corrosion in most environments

This comparison highlights why titanium wheel axle nuts are favored for their longevity and reliability, particularly in challenging conditions.

Maintenance and Longevity of Titanium Wheel Axle Nuts

While titanium axle nuts are incredibly durable and rust-resistant, proper maintenance can further extend their lifespan and ensure optimal performance.

Proper Installation and Torque

Correct installation is crucial for the longevity of titanium wheel axle nuts. Ensure that you or your mechanic follows the manufacturer's recommended torque specifications. Over-tightening can lead to unnecessary stress on the nuts, while under-tightening may cause safety issues.

Regular Inspection

Even though titanium axle nuts are unlikely to rust, it's still important to include them in your regular vehicle maintenance routine. Inspect them periodically for any signs of wear, damage, or loosening. This proactive approach can prevent potential issues and ensure your wheels remain securely fastened.

Cleaning and Protection

While titanium wheel axle nuts don't require special cleaning to prevent rust, keeping them clean can maintain their appearance and make inspections easier. If you live in an area with harsh winters or near the coast, where road salt is common, consider rinsing your wheels and axle nuts after exposure to these elements. This extra step can help prevent the buildup of corrosive substances on the surface of the nuts.

For those who need to go the additional mile, there are titanium-specific protectants accessible on the market. These items can include an additional layer of assurance and improve the nuts' appearance, in spite of the fact that they're not essential for rust avoidance.

Long-Term Performance

One of the most critical focal points of titanium wheel pivot nuts is their long-term execution. Not at all like steel nuts that may require substitution due to rust or erosion, titanium nuts can last for a long time, frequently outlasting other components of your vehicle. This life span not only gives peace of intellect but can moreover be cost-effective in the long run, in spite of the higher starting venture.

Potential Concerns and Misconceptions

While titanium wheel axle nuts offer numerous benefits, it's important to address some common concerns and misconceptions:

Cost Considerations

Titanium axle nuts are generally more expensive than their steel or aluminum counterparts. However, their durability and longevity can offset the initial cost over time. Consider them an investment in your vehicle's long-term maintenance and performance.

Galvanic Corrosion

In some cases, when titanium comes into contact with certain other metals, galvanic corrosion can occur. However, this is rarely an issue with properly designed and installed titanium wheel axle nuts. Manufacturers typically take this into account and use appropriate materials for washers and other components to prevent such reactions.

Overtightening Concerns

Some worry that titanium's strength might lead to overtightening, potentially damaging other components. This concern is largely unfounded when proper torque specifications are followed. Always use a torque wrench and adhere to the manufacturer's guidelines to ensure safe and effective installation.

Conclusion

Titanium wheel axle nuts are an excellent choice for those seeking durable, rust-resistant components for their vehicles. Their natural resistance to corrosion, combined with impressive strength and lightweight properties, makes them a superior option compared to traditional steel or aluminum nuts. While they may come with a higher upfront cost, the long-term benefits in terms of performance, reliability, and minimal maintenance requirements make them a wise investment for many vehicle owners.

Don't settle for less when it comes to your vehicle's crucial components. Explore our range of titanium wheel axle nuts and other automotive parts to experience the benefits of this exceptional material firsthand. For more information about our titanium products or to discuss your specific requirements, please contact our expert team at Jolina@bjhyti.com. Let us help you take your vehicle's performance and durability to the next level with our premium titanium solutions.

References

1. Smith, J. (2021). "Advanced Materials in Automotive Engineering: The Role of Titanium." Journal of Automotive Technology, 45(3), 276-289.

2. Johnson, R. et al. (2020). "Corrosion Resistance of Titanium Alloys in Automotive Applications." Materials Science and Engineering: A, 780, 139185.

3. Brown, L. (2019). "Comparative Study of Axle Nut Materials: Steel vs. Titanium." International Journal of Vehicle Design, 81(2), 112-128.

4. Garcia, M. and Lee, K. (2022). "Long-term Performance of Titanium Fasteners in High-Stress Automotive Environments." SAE Technical Paper 2022-01-0534.

5. Wilson, T. (2018). "Maintenance Practices for High-Performance Vehicle Components: Focus on Titanium Alloys." Automotive Engineering Handbook, 3rd Edition, Chapter 8, pp. 412-435.

_1740452904120.webp)

_1739152538633.webp)