- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why Titanium Wheel Lug Bolts Offer a Clear Advantage Over Steel Fasteners

Introduction

The choice of materials in automotive engineering directly influences vehicle performance, durability, and safety. While standard steel fasteners have served the industry for decades, titanium wheel lug bolts are increasingly regarded as a premium alternative. Their unique combination of mechanical strength, low weight, and resistance to environmental damage makes them particularly valuable for enthusiasts, motorsport teams, and manufacturers aiming to optimize performance without compromising reliability.

Titanium’s Distinct Material Properties

Unlike conventional steels, titanium alloys used for wheel bolts exhibit a balance of characteristics that align perfectly with modern performance requirements. Titanium has an exceptionally high strength-to-weight ratio, meaning it delivers comparable or greater load-bearing capacity than high-grade steel but at a much lower mass. It also forms a naturally protective oxide layer, which prevents rust and chemical degradation without the need for coatings or surface treatments. This inherent stability ensures that titanium bolts maintain their structural integrity even after prolonged exposure to water, road salt, and temperature fluctuations.

Another defining property is titanium’s ability to resist fatigue failure. In high-performance driving or track conditions, wheel fasteners experience repeated cycles of stress. Titanium’s crystal structure allows it to endure these forces without developing cracks or losing tension over time, a feature that is critical for vehicles subjected to aggressive cornering, braking, and acceleration.

Performance Gains Through Weight Reduction

Reducing unsprung and rotational mass is a fundamental principle in performance tuning. Every gram saved in components attached to the wheel assembly improves handling, braking response, and acceleration efficiency. Titanium lug bolts weigh significantly less than their steel counterparts, lowering the overall weight at each corner of the vehicle. This translates to sharper steering input, quicker suspension reactions, and a smoother ride—advantages that are highly valued in competitive motorsport as well as spirited road driving.

Corrosion Resistance and Maintenance Benefits

Steel bolts rely on protective coatings like zinc plating or chrome to resist rust. Over time, these coatings can chip or wear off, allowing moisture and chemicals to initiate corrosion. Once corrosion begins, bolts may seize, making removal difficult and potentially damaging wheels or hubs. Titanium bolts eliminate this concern entirely because their corrosion resistance is intrinsic. Even after years of use in wet, salty, or humid environments, they remain easy to install and remove without requiring chemical sprays or excessive force.

This property not only extends the lifespan of the bolts but also protects the surrounding wheel assembly. Damaged or corroded bolts can lead to improper torque, uneven wheel seating, and even compromised safety during high-speed driving.

Differences in Thermal Behavior

High-performance braking systems generate substantial heat, especially in racing or mountain driving. Steel bolts can lose strength as temperatures climb, and their protective coatings may degrade. Titanium, on the other hand, retains its mechanical properties at elevated temperatures and resists thermal expansion that might otherwise affect clamping force. As a result, titanium bolts maintain a consistent grip on the wheel even during repeated high-temperature cycles.

CNC Machining: Unlocking Full Customization

Modern CNC machining technology has made titanium lug bolts accessible beyond the aerospace sector. Precision equipment shapes each bolt to exact specifications, ensuring compatibility with specific wheels and hubs. This level of accuracy allows for custom thread pitches, seat designs, and head styles tailored to individual needs.

For enthusiasts seeking visual impact, CNC processes also make it possible to create distinctive surface finishes, from polished metallic tones to vivid anodized colors. Branding, torque markings, or unique patterns can be laser-engraved without compromising strength. The result is a product that combines technical superiority with personal customization.

Safety and Standards Compliance

Despite their advantages, titanium bolts must meet strict safety criteria to replace OEM steel fasteners. Manufacturers subject each production batch to tensile, yield, and fatigue testing. Dimensional checks ensure precise thread engagement and seat geometry, while torque validation confirms that the bolts perform correctly under standard installation practices. Reputable suppliers also align with international standards such as ISO or DIN, ensuring consistency and reliability.

Common Questions About Titanium Wheel Lug Bolts

Are titanium lug bolts suitable for daily driving

Yes. When produced by experienced manufacturers and installed to correct torque specifications, titanium bolts are just as safe as standard steel bolts for everyday use, while offering additional durability and corrosion resistance.

Do titanium bolts require different maintenance than steel bolts

They require less. Titanium’s natural corrosion resistance eliminates the need for coatings or frequent inspections for rust. However, using a small amount of anti-seize compound during installation is recommended to ensure long-term thread protection.

Can steel bolts be replaced directly with titanium bolts

Yes, as long as the new bolts match the original size, thread pitch, and seat type. Correct fitment is critical to maintaining proper wheel alignment and clamping force.

Do titanium bolts have a longer service life

When installed correctly, titanium bolts can last as long as the vehicle itself because they do not corrode and maintain their strength over time.

Conclusion

Titanium wheel lug bolts are more than a luxury upgrade; they represent a material improvement that affects performance, safety, and longevity. By offering superior strength-to-weight characteristics, permanent corrosion resistance, and high-temperature stability, titanium provides clear advantages over steel.

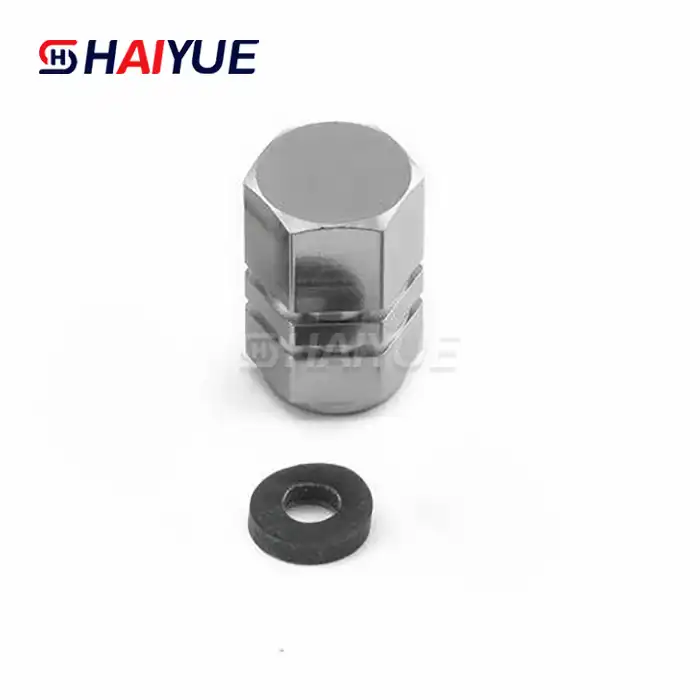

Baoji Haiyue New Metal Materials Co., Ltd. specializes in CNC precision machining and custom titanium fastener production. We provide tailored sizes, finishes, and OEM services based on drawings or physical samples.

For technical inquiries or custom orders:

Email: Jolina@bjhyti.com

Learn about our latest products and discounts through SMS or email

_1740379523581.webp)