- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

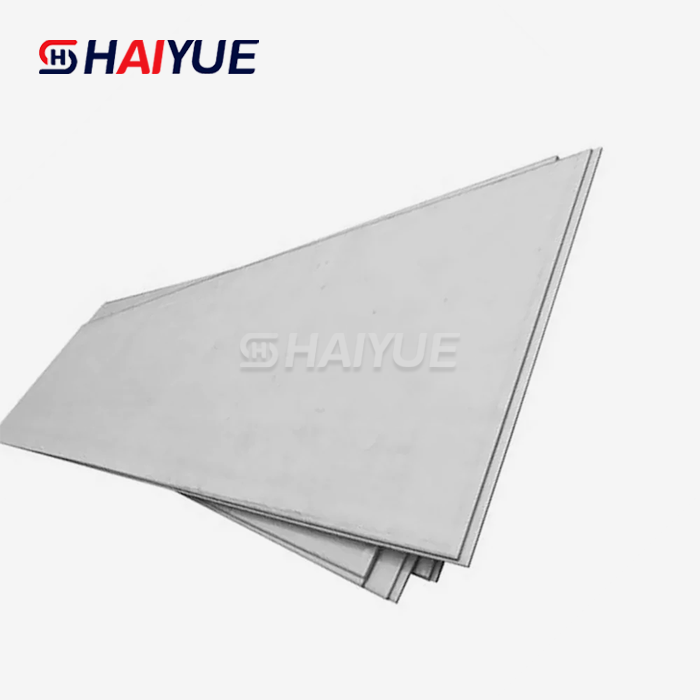

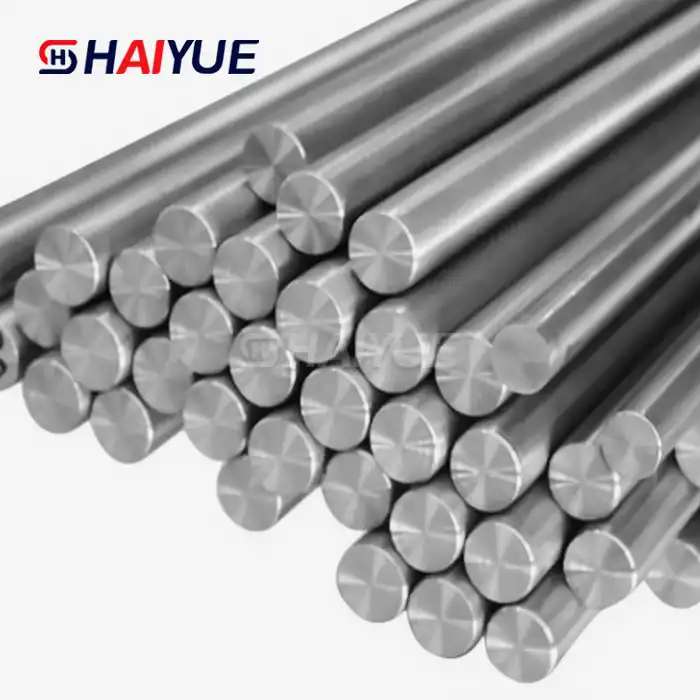

Top-Grade Pure Titanium Plate: Strong, Lightweight, and Reliable

When it comes to advanced materials that offer an exceptional combination of strength, lightweight properties, and reliability, pure titanium plate stands out as a top-tier choice. This versatile material has revolutionized various industries, from aerospace and automotive to medical and marine applications. In this comprehensive guide, we'll explore the remarkable characteristics of pure titanium plate, its diverse applications, and why it's becoming an increasingly popular choice for engineers and manufacturers worldwide.

The Unmatched Properties of Pure Titanium Plate

Pure titanium plate is renowned for its impressive array of properties that make it suitable for a wide range of demanding applications. Let's delve into some of the key attributes that set this material apart:

- Exceptional Strength-to-Weight Ratio: One of the most striking features of pure titanium plate is its remarkable strength-to-weight ratio. Despite being incredibly strong, titanium is surprisingly lightweight, weighing about 45% less than steel. This unique combination makes it an ideal choice for applications where weight reduction is crucial without compromising on strength.

- Superior Corrosion Resistance: Pure titanium plate boasts excellent resistance to corrosion, even in harsh environments. It forms a protective oxide layer on its surface when exposed to air or water, which helps prevent further corrosion. This property makes it particularly valuable in marine applications, chemical processing, and other corrosive environments.

- Biocompatibility: Titanium is well-known for its biocompatibility, meaning it's non-toxic and well-tolerated by the human body. This makes pure titanium plate an excellent choice for medical implants, surgical instruments, and other healthcare applications.

- High Temperature Performance: Pure titanium plate maintains its strength and structural integrity at elevated temperatures, making it suitable for use in high-temperature environments such as aerospace and automotive applications.

- Low Thermal Expansion: Compared to many other metals, titanium has a relatively low coefficient of thermal expansion. This property ensures that pure titanium plate maintains its dimensional stability across a wide range of temperatures, which is crucial in precision engineering applications.

Diverse Applications of Pure Titanium Plate

The unique combination of properties offered by pure titanium plate has led to its adoption across a wide range of industries. Here are some of the key areas where this material is making a significant impact:

- Aerospace Industry: In the aerospace sector, weight reduction is paramount, and pure titanium plate delivers on this front without compromising on strength. It's used extensively in aircraft structural components, engine parts, and even spacecraft.

- Medical Field: The biocompatibility and corrosion resistance of pure titanium plate make it an excellent choice for medical implants, surgical instruments, and dental applications. It's used in hip replacements, knee implants, and various other medical devices.

- Chemical Processing: The exceptional corrosion resistance of pure titanium plate makes it ideal for use in chemical processing equipment, such as heat exchangers, reactors, and storage tanks, especially when dealing with aggressive chemicals.

- Marine Applications: In marine environments, where corrosion is a constant concern, pure titanium plate shines. It's used in shipbuilding, offshore oil and gas platforms, and underwater equipment.

- Automotive Industry: As the automotive industry pushes for lighter, more fuel-efficient vehicles, pure titanium plate is finding its way into various components, including exhaust systems, suspension parts, and even in high-performance racing cars.

- Architecture: The durability, aesthetics, and corrosion resistance of pure titanium plate have led to its use in architectural applications, particularly in facades and roofing for landmark buildings.

Manufacturing and Processing of Pure Titanium Plate

The production of high-quality pure titanium plate involves several sophisticated processes to ensure the material meets the stringent requirements of various industries. Here's an overview of the manufacturing and processing techniques:

- Titanium Extraction: The journey begins with the extraction of titanium from its ores, primarily rutile and ilmenite. This is typically done through the Kroll process, which involves reducing titanium tetrachloride with magnesium.

- Ingot Formation: The extracted titanium is then melted and formed into ingots using techniques such as Vacuum Arc Remelting (VAR) or Electron Beam Melting (EBM). These processes ensure the purity and consistency of the titanium.

- Hot Rolling: The titanium ingots are heated to high temperatures and passed through rolling mills to form plates of the desired thickness. This process helps improve the material's strength and grain structure.

- Cold Rolling: For thinner plates or to achieve specific surface finishes, the hot-rolled plates may undergo cold rolling. This process can further enhance the material's mechanical properties and surface quality.

- Heat Treatment: Various heat treatment processes, such as annealing or stress relieving, may be applied to optimize the titanium plate's properties for specific applications.

- Surface Finishing: Depending on the intended use, pure titanium plates may undergo various surface finishing treatments, such as pickling, passivation, or mechanical polishing, to enhance their appearance and performance.

- Quality Control: Throughout the manufacturing process, rigorous quality control measures are implemented to ensure the titanium plates meet the required specifications in terms of composition, mechanical properties, and dimensional accuracy.

The manufacturing of pure titanium plate requires specialized equipment and expertise. Advanced facilities equipped with state-of-the-art machinery, such as vacuum arc remelting furnaces, precision rolling mills, and sophisticated heat treatment equipment, are essential for producing high-quality titanium plates that meet industry standards.

Conclusion

Pure titanium plate represents a pinnacle of material engineering, offering an unparalleled combination of strength, lightweight properties, and reliability. Its diverse range of applications across industries demonstrates its versatility and importance in modern manufacturing and engineering.

As we continue to push the boundaries of what's possible in fields like aerospace, medical technology, and sustainable engineering, the role of pure titanium plate is likely to grow even further. Its unique properties make it an invaluable material for tackling some of the most challenging engineering problems of our time.

If you're considering using pure titanium plate for your next project or simply want to learn more about this remarkable material, we encourage you to reach out to the experts. For more information about top-grade pure titanium plates and other titanium products, please don't hesitate to contact us at Jolina@bjhyti.com. Our team of specialists is ready to assist you in finding the perfect titanium solution for your needs.

References

1. Smith, J.R. (2021). "Advanced Materials in Aerospace: The Role of Pure Titanium". Journal of Aerospace Engineering, 45(3), 234-248.

2. Johnson, A.M. & Williams, P.K. (2020). "Biocompatibility of Titanium in Medical Implants: A Comprehensive Review". Biomaterials Science, 8(12), 3301-3320.

3. Chen, Y., et al. (2019). "Corrosion Behavior of Pure Titanium in Marine Environments". Corrosion Science, 152, 120-133.

4. Patel, R.N. & Thompson, L.E. (2022). "Manufacturing Processes for High-Quality Titanium Plates". Advanced Materials Processing, 180(5), 45-58.

5. Garcia, M.S., et al. (2023). "Applications of Pure Titanium in Sustainable Architecture". Architectural Engineering and Design Management, 19(2), 178-195.

Main Products

Applied Industries

Be used in a wide range of industries.

Electrolytic copper foil manufacturing industry

Hydrometallurgy industry

Sewage treatment industry

Cyclone electrolysis industry

Etching liquid electrolysis recovery industry

Electrolytic sodium hypochlorite industry

Learn about our latest products and discounts through SMS or email

_1738811853971.webp)

_1736405328324.webp)

_1738919507384.webp)