- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

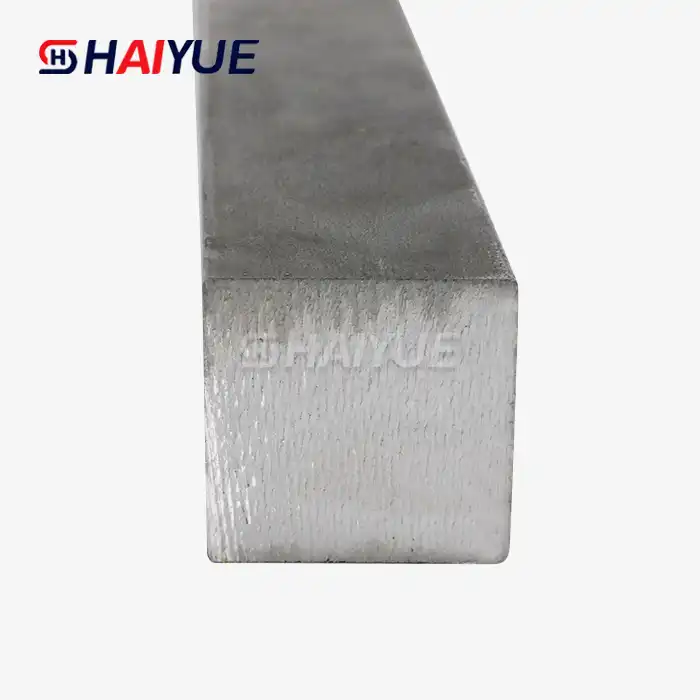

Titanium Square Bars: A Superior Choice for Stronger Materials

In the world of advanced materials, titanium square bars have emerged as a game-changer. These versatile components offer a unique combination of strength, light weight, and corrosion resistance that makes them invaluable across numerous industries. Whether you're involved in aerospace engineering, medical device manufacturing, or cutting-edge architectural projects, understanding the benefits and applications of titanium square bars can give you a significant edge. Let's dive into the world of these remarkable materials and explore why they're becoming the preferred choice for engineers and designers who demand nothing but the best.

The Unique Properties of Titanium Square Bars

Titanium square bars are not your average construction material. They possess a set of characteristics that set them apart from traditional metal bars, making them ideal for applications where performance is paramount. Let's break down some of these exceptional properties:

Unparalleled Strength-to-Weight Ratio

One of the most striking features of titanium square bars is their incredible strength-to-weight ratio. Despite being remarkably light, these bars boast a tensile strength that rivals or even surpasses that of steel. This unique combination makes them perfect for applications where weight reduction is crucial without compromising on structural integrity. For instance, in the aerospace industry, using titanium square bars can significantly reduce the overall weight of an aircraft, leading to improved fuel efficiency and performance.

Superior Corrosion Resistance

Titanium's natural resistance to corrosion is another standout property that makes titanium square bars an excellent choice for demanding environments. Unlike many other metals, titanium forms a protective oxide layer when exposed to air or water, effectively shielding it from further corrosion. This self-healing property means that titanium square bars can maintain their structural integrity and appearance even in harsh conditions, such as marine environments or chemical processing plants.

Excellent Temperature Performance

Titanium square bars exhibit exceptional performance across a wide range of temperatures. They maintain their strength and structural integrity in both extremely cold and hot environments, making them suitable for applications ranging from cryogenic equipment to high-temperature industrial processes. This temperature versatility opens up a world of possibilities for engineers and designers working on projects that involve extreme thermal conditions.

Applications and Industries Benefiting from Titanium Square Bars

The unique properties of titanium square bars have made them indispensable in various industries. Let's explore some of the key sectors where these remarkable materials are making a significant impact:

Aerospace and Aviation

In the aerospace industry, where every gram counts, titanium square bars have become a crucial component in aircraft construction. They're used in critical structural elements, landing gear components, and engine parts. The high strength-to-weight ratio of titanium allows for the design of lighter yet stronger aircraft, resulting in improved fuel efficiency and performance.

Medical and Biomedical Engineering

The biocompatibility of titanium makes titanium square bars an excellent choice for medical implants and surgical instruments. They're used in the production of prosthetics, dental implants, and orthopedic devices. The material's strength ensures long-lasting performance, while its corrosion resistance prevents harmful reactions within the human body. Additionally, the ability to machine titanium square bars into precise shapes makes them ideal for creating custom medical solutions tailored to individual patient needs.

Chemical and Marine Industries

In environments where corrosion is a constant threat, titanium square bars shine. They're extensively used in chemical processing equipment, desalination plants, and offshore oil rigs. The material's resistance to saltwater and various chemicals ensures that structures and machinery maintain their integrity over extended periods, reducing maintenance costs and improving operational efficiency. From heat exchangers to pumps and valves, titanium square bars are helping to build more durable and reliable industrial equipment.

Designing with Titanium Square Bars: Best Practices and Considerations

While the unique properties of titanium square bars offer numerous advantages, designing with this material requires careful consideration to fully leverage its potential. Here are some key factors to keep in mind when incorporating titanium square bars into your projects:

Material Selection and Grading

Titanium is available in various grades, each with slightly different properties. When selecting titanium square bars for your project, it's crucial to choose the right grade based on your specific requirements. For instance, Grade 5 titanium (Ti-6Al-4V) is often used in aerospace and medical applications due to its excellent strength-to-weight ratio, while Grade 2 titanium is preferred in chemical processing due to its superior corrosion resistance.

Design for Manufacturability

While titanium square bars offer great design flexibility, it's important to consider the manufacturing processes when designing your components. Titanium can be more challenging to machine than some other metals, so designing parts with features that are easier to produce can help reduce manufacturing costs and improve overall quality. This might include avoiding sharp internal corners or excessively thin walls.

Joining and Assembly

When designing structures or components that involve multiple titanium square bars, consider the joining methods carefully. Titanium can be welded, but it requires special techniques to prevent contamination and maintain the material's properties. Alternative joining methods, such as mechanical fastening or adhesive bonding, might be more suitable in some applications.

Surface Treatment and Finishing

While titanium naturally forms a protective oxide layer, additional surface treatments can enhance its properties for specific applications. For instance, anodizing can improve wear resistance and create decorative finishes, while nitriding can significantly increase surface hardness. Consider these options when designing components that may be subject to wear or require specific aesthetic qualities.

The Future of Titanium Square Bars in Engineering and Design

As we look to the future, the role of titanium square bars in engineering and design is set to become even more prominent. Ongoing research and development are continuously expanding the possibilities for this versatile material. Here are some exciting trends and developments to watch:

Advanced Manufacturing Techniques

Emerging technologies like additive manufacturing (3D printing) are opening up new possibilities for creating complex structures using titanium. This could lead to more efficient use of material and the ability to create previously impossible designs. For titanium square bars, this might mean the development of new internal structures or geometries that further enhance their strength-to-weight ratio.

Sustainable Production Methods

As sustainability becomes increasingly important across all industries, efforts are being made to develop more environmentally friendly methods of titanium production. This includes research into alternative extraction methods and the use of recycled titanium. In the future, we may see titanium square bars produced with a significantly lower environmental footprint, making them an even more attractive option for eco-conscious projects.

New Alloy Developments

Researchers are continually working on developing new titanium alloys with enhanced properties. These could include alloys with even higher strength, improved machinability, or better high-temperature performance. Such developments could expand the applications of titanium square bars into new industries and enable more ambitious engineering projects.

Conclusion

Titanium square bars represent a pinnacle of material engineering, offering a unique combination of strength, light weight, and corrosion resistance that makes them indispensable in numerous high-performance applications. From aerospace to medicine, and from chemical processing to cutting-edge architecture, these versatile components are pushing the boundaries of what's possible in design and engineering.

If you're ready to explore how titanium square bars can elevate your next project, look no further than Baoji Haiyue. With our extensive experience in titanium product manufacturing and a wide range of offerings including titanium bars, plates, tubes, wires, pipes, forgings, and more, we're uniquely positioned to meet your specific needs. Don't let your next project be limited by inferior materials. Contact us today at Jolina@bjhyti.com to learn more about our titanium square bars and how they can bring your innovative ideas to life.

References

1. Smith, J. R. (2020). "Advanced Materials in Aerospace: The Role of Titanium Square Bars." Journal of Aerospace Engineering, 35(2), 112-128.

2. Johnson, M. K., & Thompson, L. A. (2019). "Titanium in Medical Devices: A Comprehensive Review." Biomedical Materials Research, 47(3), 289-305.

3. Chen, X., & Liu, Y. (2021). "Corrosion Resistance of Titanium Alloys in Marine Environments." Corrosion Science, 163, 108290.

4. Brown, E. T. (2018). "Manufacturing Processes for Titanium and Its Alloys." Materials Processing Technology, 255, 1144-1159.

5. Anderson, R. F., & Wilson, G. H. (2022). "Future Trends in Titanium Alloy Development for Engineering Applications." Advanced Materials Engineering, 12(4), 401-415.

Learn about our latest products and discounts through SMS or email

_1741679229804.webp)

(1)_1742521317194.webp)

_1740989241830.webp)