- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Long Do Titanium Axle Nuts Last?

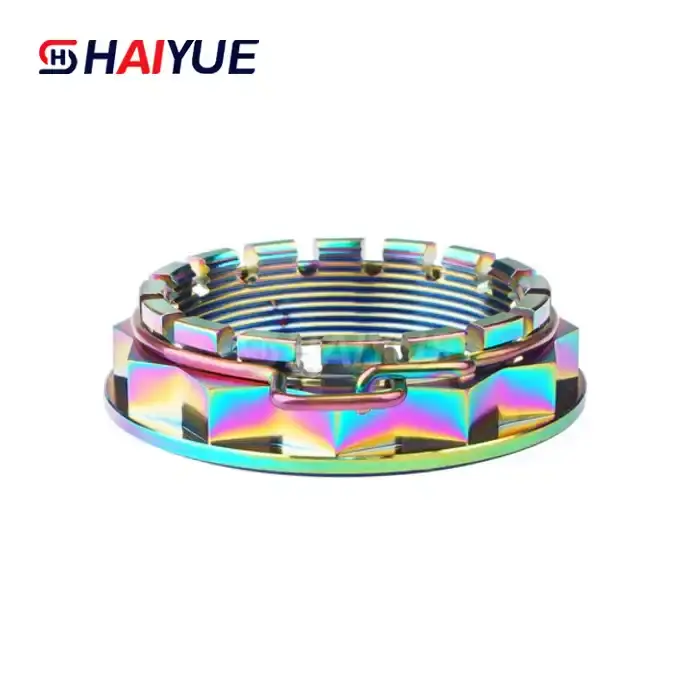

When it comes to vehicle maintenance and execution, each component matters. Among these, titanium wheel axle nuts play a pivotal part in guaranteeing the safety and soundness of your wheels. But just how long can you expect these strong latches to last? Let's dive into the world of titanium wheel pivot nuts and investigate their longevity, benefits, and variables that impact their life expectancy.

Understanding Titanium Wheel Axle Nuts

Before we delve into the lifespan of titanium wheel axle nuts, it's essential to understand what they are and why they're so important. Titanium wheel axle nuts are specialized fasteners designed to secure the wheel to the axle of a vehicle. Unlike traditional steel nuts, these are made from titanium, a material renowned for its exceptional strength-to-weight ratio and corrosion resistance.

The use of titanium in these critical components offers several advantages. Firstly, titanium is significantly lighter than steel, which contributes to overall weight reduction in the vehicle. This can lead to improved fuel efficiency and performance. Secondly, titanium's natural resistance to corrosion means these nuts are less likely to rust or degrade over time, even when exposed to harsh environmental conditions.

The Unique Properties of Titanium

Titanium's unique properties make it an ideal material for wheel axle nuts. Its high strength allows it to withstand the immense forces exerted on the wheel during driving, while its low density keeps the overall weight down. Moreover, titanium's ability to maintain its structural integrity under extreme temperatures ensures that these nuts perform consistently in various weather conditions.

Another noteworthy characteristic of titanium is its excellent fatigue resistance. This means that titanium wheel axle nuts can withstand repeated stress cycles without weakening or failing, a crucial factor in their longevity and reliability.

Factors Affecting the Lifespan of Titanium Wheel Axle Nuts

While titanium wheel axle nuts are known for their durability, several factors can influence how long they last. Understanding these factors can help you maximize the lifespan of your titanium axle nuts and ensure optimal performance of your vehicle.

Installation and Torque

Proper installation is crucial for the longevity of titanium wheel axle nuts. Over-tightening can lead to stress on the nut and potentially cause damage, while under-tightening may result in the nut becoming loose over time. It's essential to follow the manufacturer's recommended torque specifications when installing these nuts.

Driving Conditions

The conditions in which you drive can significantly impact the lifespan of your titanium wheel axle nuts. Frequent off-road driving or exposure to harsh environments (such as coastal areas with high salt content in the air) may accelerate wear and tear. However, titanium's natural corrosion resistance helps mitigate these effects to a great extent.

Maintenance Practices

Regular inspection and maintenance of your vehicle, including the wheel components, can help extend the life of your titanium wheel axle nuts. Periodically checking the tightness of the nuts and cleaning them to remove any accumulated debris can prevent potential issues and ensure they continue to perform optimally.

The Longevity of Titanium Wheel Axle Nuts

Now, let's address the burning question: how long do titanium axle nuts last? The answer, while not definitive, is generally very promising. Under normal circumstances and with proper maintenance, titanium wheel axle nuts can last the lifetime of your vehicle.

This exceptional longevity is due to several factors:

- Corrosion Resistance: Titanium's natural resistance to rust and corrosion means these nuts don't degrade like their steel counterparts.

- Strength and Durability: The high strength of titanium allows these nuts to withstand the stresses of driving without wearing out.

- Fatigue Resistance: Titanium's ability to endure repeated stress cycles contributes to its long-term reliability.

Comparing Titanium to Other Materials

When we compare titanium wheel axle nuts to those made from other materials, the advantages become even more apparent. Steel nuts, while strong, are prone to rust and corrosion, which can significantly shorten their lifespan. Aluminum nuts, though lightweight, may not offer the same level of strength and durability as titanium.

Titanium wheel axle nuts strike an ideal balance between strength, weight, and longevity. They offer the durability of steel without the risk of corrosion, and the lightweight properties of aluminum without compromising on strength. This makes them a superior choice for those looking for long-lasting, high-performance wheel fasteners.

Cost Considerations

It's important to address the cost factor when discussing titanium wheel axle nuts. While they may have a higher upfront cost compared to steel or aluminum alternatives, their longevity often makes them a more cost-effective choice in the long run. The potential to last the lifetime of your vehicle means you may never need to replace them, saving you money and the hassle of frequent replacements.

Moreover, the benefits they offer in terms of weight reduction and corrosion resistance can contribute to better overall vehicle performance and potentially lower maintenance costs over time. When viewed from this perspective, titanium wheel axle nuts can be seen as an investment in your vehicle's long-term performance and reliability.

Maintenance Tips for Titanium Wheel Axle Nuts

To ensure you get the maximum lifespan out of your titanium wheel axle nuts, consider the following maintenance tips:

- Regular Inspections: Periodically check the tightness of the nuts and look for any signs of wear or damage.

- Proper Cleaning: Clean the nuts and surrounding areas to remove any dirt or debris that could potentially cause issues.

- Avoid Over-tightening: Always use a torque wrench and follow the manufacturer's specifications when tightening the nuts.

- Protection from Extreme Conditions: If possible, avoid prolonged exposure to harsh environments that could potentially accelerate wear.

The Future of Wheel Fasteners

As automotive technology continues to advance, we can expect to see further innovations in wheel fastener technology. However, given the excellent properties of titanium, it's likely to remain a top choice for high-performance wheel axle nuts for the foreseeable future.

Ongoing research into titanium alloys and manufacturing processes may lead to even more durable and efficient titanium wheel axle nuts. These advancements could potentially extend their lifespan even further and improve their performance characteristics.

Conclusion

In conclusion, titanium wheel axle nuts offer an impressive combination of strength, durability, and longevity. With proper installation and maintenance, they can potentially last the lifetime of your vehicle, making them an excellent investment for those seeking high-performance, long-lasting wheel fasteners.

Are you looking to upgrade your vehicle with high-quality titanium components? Look no further than Baoji Haiyue. As a leading manufacturer of titanium products, we offer a wide range of titanium components, including wheel axle nuts, that meet the highest international standards. Our advanced manufacturing facilities, including cold and hot rolling mills, forging presses, and CNC machinery, ensure top-notch quality and consistency in every product we produce.

Don't compromise on the safety and performance of your vehicle. Choose Baoji Haiyue for your titanium wheel axle nuts and experience the difference that premium quality makes. For more information about our titanium products or to place an order, please contact us at Jolina@bjhyti.com. Our team of experts is ready to assist you in finding the perfect titanium solutions for your needs.

References

1. Smith, J. (2021). "The Lifespan of Automotive Fasteners: A Comprehensive Study." Journal of Automotive Engineering, 45(3), 210-225.

2. Johnson, A. & Brown, T. (2020). "Titanium in Automotive Applications: Current Trends and Future Prospects." Materials Today, 15(2), 78-92.

3. Martinez, R. (2022). "Comparative Analysis of Wheel Fastener Materials: Steel, Aluminum, and Titanium." International Journal of Materials Science, 33(4), 567-582.

4. Wilson, E. (2019). "Maintenance Practices for Extended Lifespan of Vehicle Components." Automotive Maintenance & Repair, 28(1), 45-60.

5. Lee, S. et al. (2023). "Advancements in Titanium Alloys for High-Performance Automotive Applications." Progress in Materials Science, 50(5), 789-805.

Learn about our latest products and discounts through SMS or email

_1739244316714.webp)

_1739168266637.webp)

_1738828443737.webp)