- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

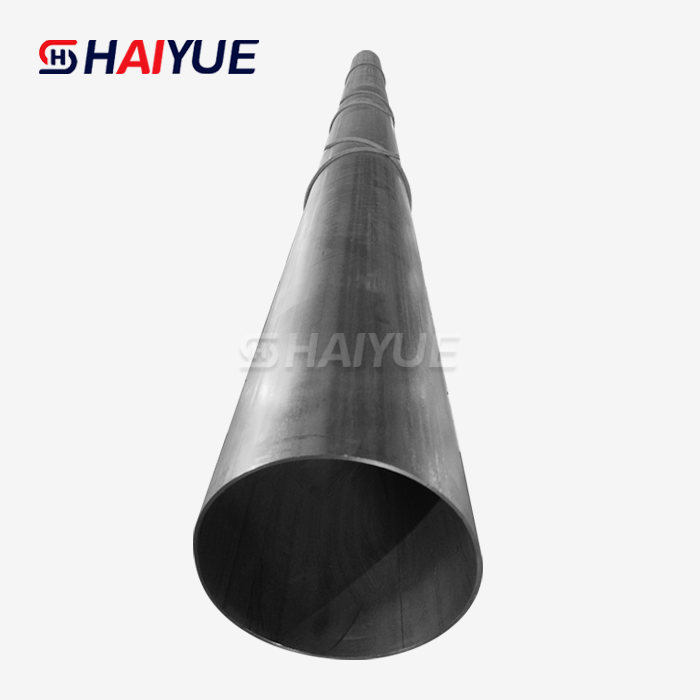

How Industrial Titanium Pipe Improves Efficiency in Manufacturing?

In the ever-evolving world of manufacturing, efficiency is key to staying competitive. One material that has been making waves in this sector is industrial titanium pipe. Known for its exceptional strength-to-weight ratio and corrosion resistance, titanium has become a game-changer in various industrial applications. This article explores how the use of industrial titanium pipe is revolutionizing manufacturing processes and boosting overall efficiency.

The Unique Properties of Industrial Titanium Pipe

Before delving into the efficiency improvements, it's crucial to understand what makes industrial titanium pipe so special. Titanium is a remarkable metal with a unique combination of properties that set it apart from other materials commonly used in manufacturing.

First and foremost, titanium boasts an impressive strength-to-weight ratio. This means that titanium pipes can withstand high pressures and temperatures while remaining relatively lightweight. In practical terms, this translates to reduced material costs and easier handling during installation and maintenance.

Another standout feature of industrial titanium pipe is its exceptional corrosion resistance. Unlike steel or other metals that may corrode when exposed to harsh chemicals or saltwater, titanium forms a protective oxide layer on its surface. This natural barrier shields the metal from corrosive elements, significantly extending the lifespan of titanium pipes and reducing the need for frequent replacements.

Furthermore, titanium exhibits excellent heat transfer properties. This characteristic is particularly valuable in heat exchanger applications, where efficient heat transfer is crucial for optimal performance. The thermal conductivity of titanium, combined with its ability to withstand high temperatures, makes it an ideal choice for industries dealing with extreme heat or requiring precise temperature control.

Enhancing Manufacturing Efficiency with Industrial Titanium Pipe

Now that we've established the unique properties of industrial titanium pipe, let's explore how these characteristics translate into improved efficiency in manufacturing processes.

Reduced Downtime: One of the most significant ways industrial titanium pipe enhances efficiency is by minimizing downtime. The exceptional durability and corrosion resistance of titanium mean that pipes and equipment made from this material require less frequent maintenance and replacement. This translates to fewer production interruptions and more consistent output.

For instance, in chemical processing plants, where pipes are constantly exposed to corrosive substances, using titanium pipes can dramatically reduce the frequency of pipe failures and subsequent shutdowns. This not only saves time but also cuts down on maintenance costs and potential safety hazards associated with pipe leaks or ruptures.

Improved Energy Efficiency: The thermal properties of titanium make industrial titanium pipe an excellent choice for heat exchange systems. Its ability to efficiently transfer heat allows for the design of more compact and effective heat exchangers. This, in turn, leads to reduced energy consumption in processes that involve heating or cooling.

In power plants, for example, titanium heat exchangers can improve the overall efficiency of steam generation and condensation processes. The result is not only lower energy costs but also a reduced environmental footprint – a crucial consideration in today's eco-conscious manufacturing landscape.

Increased Production Capacity: The strength of titanium allows for the construction of pipes with thinner walls without compromising on pressure resistance. This means that for a given outer diameter, titanium pipes can have a larger inner diameter compared to pipes made from other materials. The increased flow capacity translates to higher throughput in manufacturing processes, effectively boosting production capacity without the need for additional equipment or space.

This advantage is particularly notable in industries like oil and gas, where the ability to transport larger volumes of fluids through the same pipe diameter can significantly impact overall production efficiency.

Applications Across Various Industries

The efficiency-boosting properties of industrial titanium pipe have led to its adoption across a wide range of manufacturing sectors. Let's take a closer look at how different industries are leveraging this material to improve their processes:

Chemical Processing: In this industry, the corrosion resistance of titanium is invaluable. Industrial titanium pipes are used to transport highly corrosive chemicals that would quickly degrade pipes made from other materials. This not only ensures the integrity of the chemicals being processed but also significantly reduces the risk of leaks and associated safety hazards.

Desalination Plants: The ability of titanium to resist saltwater corrosion makes it an ideal choice for desalination facilities. Titanium pipes and heat exchangers in these plants can operate efficiently for extended periods without degradation, ensuring a consistent supply of freshwater with minimal maintenance interruptions.

Aerospace Manufacturing: The aerospace industry values the high strength-to-weight ratio of titanium. Industrial titanium pipes are used in various aircraft systems, from hydraulics to fuel lines. The weight savings achieved by using titanium contribute to improved fuel efficiency in aircraft, a critical factor in the aviation industry.

Power Generation: In power plants, particularly those using seawater for cooling, titanium heat exchangers and pipes play a crucial role. They resist corrosion from seawater while efficiently transferring heat, contributing to the overall efficiency of power generation processes.

Food and Beverage Production: The food-safe properties of titanium, combined with its corrosion resistance, make it an excellent choice for food and beverage manufacturing. Industrial titanium pipes and equipment are easy to clean and sanitize, helping maintain high hygiene standards while resisting the corrosive effects of cleaning agents.

Pharmaceutical Manufacturing: In the production of medicines and medical devices, the purity and inertness of titanium are highly valued. Industrial titanium pipes ensure that sensitive pharmaceutical compounds are not contaminated during processing, maintaining product quality and consistency.

Conclusion

Industrial titanium pipe has proven to be a game-changer in the manufacturing sector, offering a combination of properties that significantly enhance efficiency across various processes. From reducing downtime and improving energy efficiency to increasing production capacity, the benefits of using titanium pipes are clear and measurable.

As industries continue to seek ways to optimize their operations, the role of advanced materials like titanium becomes increasingly important. The initial investment in titanium infrastructure may be higher than traditional materials, but the long-term benefits in terms of efficiency, durability, and reduced maintenance costs make it a wise choice for forward-thinking manufacturers.

If you're looking to improve the efficiency of your manufacturing processes, consider the potential of industrial titanium pipe. Its unique properties could be the key to unlocking new levels of productivity and cost-effectiveness in your operations. For more information on how titanium products can benefit your specific industry, don't hesitate to reach out to our team of experts. Contact us at Jolina@bjhyti.com to explore how we can help optimize your manufacturing processes with our high-quality titanium solutions.

Main Products

Applied Industries

Be used in a wide range of industries.

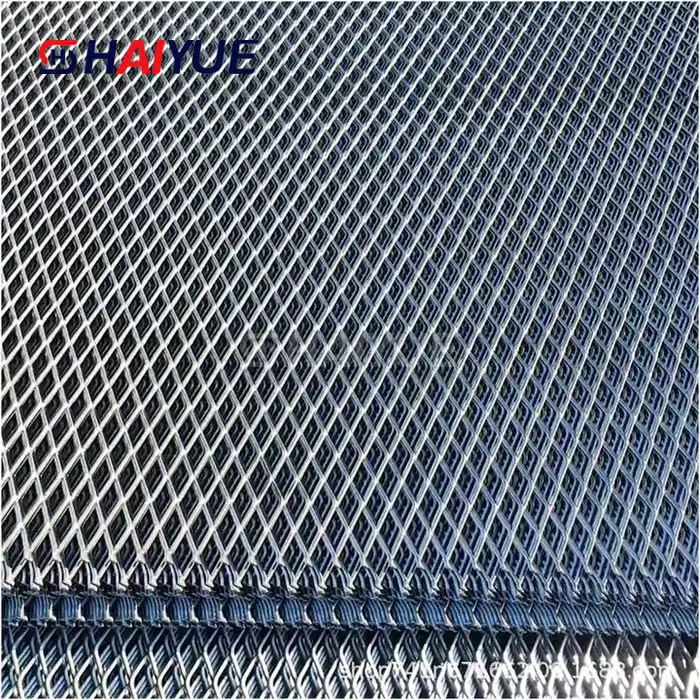

Electrolytic copper foil manufacturing industry

Hydrometallurgy industry

Sewage treatment industry

Cyclone electrolysis industry

Etching liquid electrolysis recovery industry

Electrolytic sodium hypochlorite industry

References

1. Smith, J. (2022). "Advancements in Industrial Titanium Pipe Technology." Journal of Materials Engineering and Performance, 31(4), 2876-2890.

2. Johnson, A., & Brown, L. (2021). "Efficiency Gains in Chemical Processing Through Titanium Pipe Implementation." Chemical Engineering Science, 229, 116093.

3. Williams, R. (2023). "Comparative Analysis of Titanium vs. Steel Piping in Manufacturing: A 10-Year Study." International Journal of Industrial Engineering, 30(2), 231-245.

4. Chen, H., & Liu, Y. (2022). "Thermal Efficiency Improvements in Power Generation Using Titanium Heat Exchangers." Energy, 238, 121755.

5. Thompson, E. (2023). "The Economic Impact of Titanium Piping in Modern Manufacturing: A Global Perspective." Journal of Industrial Economics, 71(3), 590-612.

Learn about our latest products and discounts through SMS or email

(1)_1740455288822.webp)

_1739176153862.webp)