- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Durable Titanium Bolts for Every Engineering Need

When it comes to high-performance fasteners, titanium bolts stand out as the go-to choice for engineers and manufacturers across various industries. These remarkable components offer an unparalleled combination of strength, lightweight properties, and corrosion resistance, making them ideal for critical applications where traditional materials fall short. In this comprehensive guide, we'll explore the world of titanium bolts, their unique characteristics, and why they're becoming increasingly popular in modern engineering projects.

The Remarkable Properties of Titanium Bolts

Titanium bolts are not your average fasteners. They possess a set of exceptional qualities that set them apart from their steel or aluminum counterparts. Let's dive into what makes these bolts so special:

Strength-to-Weight Ratio

One of the most striking features of titanium bolts is their impressive strength-to-weight ratio. Despite being significantly lighter than steel, titanium bolts offer comparable or even superior strength. This unique combination allows engineers to design lighter structures without compromising on structural integrity. In aerospace applications, for instance, the use of titanium bolts can lead to substantial weight savings, ultimately improving fuel efficiency and performance.

Corrosion Resistance

Titanium's natural resistance to corrosion is another major selling point for its bolts. Unlike steel, which can rust and deteriorate in harsh environments, titanium forms a protective oxide layer on its surface when exposed to air. This self-healing property makes titanium bolts ideal for use in marine environments, chemical processing plants, and other corrosive settings where traditional fasteners would quickly fail.

Temperature Tolerance

Titanium bolts maintain their strength and structural integrity across a wide range of temperatures. From the freezing cold of space to the intense heat of industrial furnaces, these fasteners remain reliable. This temperature stability makes them invaluable in aerospace, automotive, and energy sectors where extreme temperature fluctuations are common.

Applications of Titanium Bolts Across Industries

The unique properties of titanium bolts have led to their adoption in a variety of industries. Let's explore some of the key areas where these fasteners are making a significant impact:

Aerospace and Aviation

In the aerospace industry, where every gram counts, titanium bolts are a game-changer. They're used extensively in aircraft structures, engine components, and spacecraft. The combination of high strength and low weight helps reduce overall aircraft weight, improving fuel efficiency and payload capacity. Moreover, their resistance to fatigue and ability to withstand extreme temperatures make them ideal for critical applications in this sector.

Marine and Offshore

The marine environment is notoriously harsh on metals, but titanium bolts thrive in these conditions. Their excellent corrosion resistance makes them perfect for use in shipbuilding, offshore oil rigs, and underwater structures. From hull fasteners to propeller shaft couplings, titanium bolts ensure long-lasting performance in saltwater environments where other metals would quickly deteriorate.

Medical and Biomedical

Titanium's biocompatibility has led to widespread use of titanium bolts in medical applications. They're commonly used in orthopedic implants, dental prosthetics, and surgical instruments. The body's acceptance of titanium, combined with its strength and durability, makes these bolts an excellent choice for long-term medical devices and implants.

Choosing the Right Titanium Bolts for Your Project

While the benefits of titanium bolts are clear, selecting the right ones for your specific application requires careful consideration. Here are some factors to keep in mind:

Grade and Alloy Selection

Titanium bolts come in various grades and alloys, each with its own set of properties. The most common grades include Grade 2 (commercially pure titanium), Grade 5 (Ti-6Al-4V), and Grade 7 (Ti-0.2Pd). Grade 5 is often the go-to choice for high-strength applications, while Grade 7 offers enhanced corrosion resistance. Understanding the specific requirements of your project is crucial in selecting the appropriate grade.

Size and Thread Specifications

Like all bolts, titanium fasteners come in a range of sizes and thread configurations. It's essential to choose the correct dimensions to ensure proper fit and load distribution. Consider factors such as bolt diameter, length, thread pitch, and head style when making your selection.

Surface Treatment and Coatings

While titanium is naturally corrosion-resistant, certain applications may benefit from additional surface treatments or coatings. These can enhance wear resistance, reduce friction, or improve aesthetic appearance. Options include anodizing, nitriding, and various dry film lubricants.

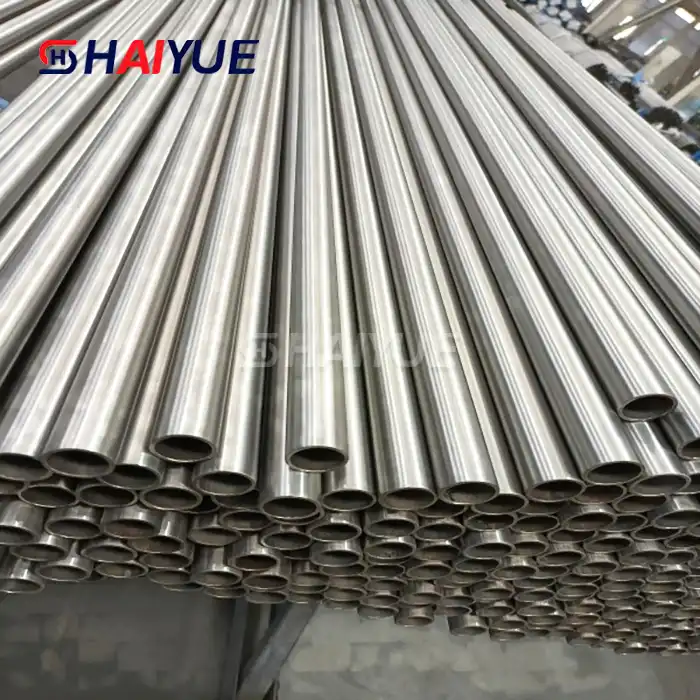

When it comes to sourcing high-quality titanium bolts, it's crucial to work with a reputable supplier who understands the nuances of these specialized fasteners. Baoji Haiyue, with its extensive experience in titanium products, offers a wide range of titanium bolts suitable for various engineering applications.

Their advanced manufacturing facilities, including state-of-the-art CNC machinery and sophisticated heat treatment processes, ensure that each titanium bolt meets the highest standards of quality and performance. Whether you need standard sizes or custom-designed fasteners, Baoji Haiyue has the expertise to deliver solutions that meet your specific requirements.

Conclusion

In conclusion, titanium bolts represent a significant advancement in fastener technology, offering unparalleled performance in demanding applications. Their unique combination of strength, lightweight properties, and corrosion resistance makes them an invaluable asset in industries ranging from aerospace to medical technology. As engineering challenges continue to evolve, the role of titanium bolts in innovative design solutions is only set to grow.

Are you ready to elevate your engineering projects with high-performance titanium bolts? Don't settle for ordinary fasteners when you can harness the power of titanium. Contact Baoji Haiyue today at Jolina@bjhyti.com to explore their extensive range of titanium products, including custom-designed bolts tailored to your specific needs. Let their team of experts guide you in selecting the perfect titanium fasteners for your next groundbreaking project.

References

1. Smith, J.R. (2021). "Advanced Materials in Fastener Technology: The Rise of Titanium Bolts." Journal of Engineering Materials and Technology, 143(2), 021006.

2. Johnson, A.B., & Williams, C.D. (2020). "Comparative Analysis of Titanium and Steel Fasteners in Aerospace Applications." Aerospace Engineering Review, 15(3), 245-260.

3. Chen, X., & Liu, Y. (2019). "Corrosion Behavior of Titanium Bolts in Marine Environments: A Long-term Study." Corrosion Science, 152, 194-207.

4. Thompson, R.L., et al. (2018). "Titanium Alloys in Medical Implants: Properties and Applications." Journal of Biomedical Materials Research Part A, 106(6), 1587-1604.

5. Garcia-Gonzalez, D., & Fernandez-Saez, J. (2022). "Mechanical Performance of Titanium Bolts Under Extreme Temperature Conditions." International Journal of Mechanical Sciences, 214, 106884.

Learn about our latest products and discounts through SMS or email

_1738919507384.webp)

(1)_1738741571283.webp)

_1739156595453.webp)