- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Are titanium lug nuts worth it?

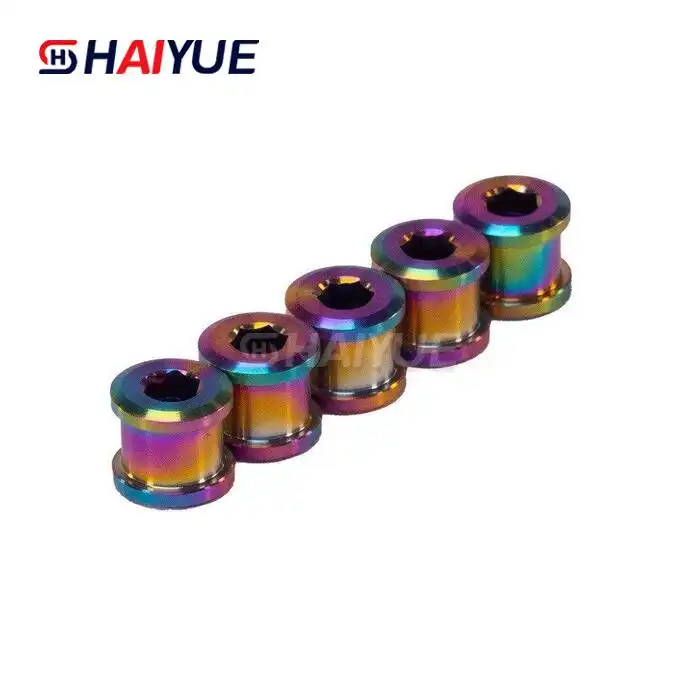

As a professional buyer, performance parts distributor, or auto parts importer, you're constantly faced with choices that impact both your customers and your bottom line. Among the most frequently underestimated upgrades are wheel lug nuts—specifically, Titanium Wheel Lug Nuts With Polished Finish. With rising demand across the global aftermarket for both performance and aesthetics, titanium lug nuts are rapidly becoming a preferred upgrade. But are they truly worth the investment? Do they offer measurable value beyond their sleek appearance?

For sourcing professionals and distributors, understanding the true value behind titanium wheel lug nuts is essential—this article dives into the data, benefits, and real-world applications driving global demand.

Do Titanium Lug Nuts Rust?

Corrosion is a silent killer in the automotive world. Whether your clients operate in coastal cities, high-humidity countries, or cold regions where roads are frequently salted, rusted lug nuts are a recurring pain point.

Here’s the advantage of titanium: it does not rust—ever.

Why? Titanium naturally forms a passivating oxide layer that prevents rust and corrosion. Unlike steel lug nuts that require chrome plating or zinc coatings (which eventually chip or wear off), titanium is corrosion-resistant by nature. That means:

No discoloration over time

No seizing or thread galling due to rust

No need for replacements every season

The polished finish on these lug nuts further enhances their durability and appearance, offering a premium, mirror-like sheen that won't degrade, flake, or require maintenance.

From a procurement standpoint, titanium lug nuts reduce return rates, lower replacement costs, and enhance your product's reputation in harsh-weather markets. When buyers in Europe, North America, or coastal Southeast Asia ask about longevity, titanium is your bulletproof answer.

Are Titanium Lug Nuts Safe?

As a buyer, product safety and liability are always top priorities. You're not just sourcing a fastener—you’re responsible for something that holds wheels onto high-speed vehicles. One product failure could damage your brand, reputation, and client relationships.

Fortunately, Grade 5 Titanium (Ti-6Al-4V) is a proven aerospace alloy known for its:

Tensile strength of up to 950 MPa

Excellent fatigue resistance

Stability in high-heat environments (ideal for high-performance brake systems)

When properly installed using recommended torque values and anti-seize lubricant, titanium lug nuts are extremely safe for both track and street use.

Key Safety Highlights:

Thread Precision: Our CNC-machined titanium lug nuts guarantee accurate fitment and consistent clamping force.

Heat Resistance: Ideal for motorsports or performance builds where brake heat can compromise steel or aluminum fasteners.

Gall-Resistant Coating Options: Although titanium is prone to galling, proper surface treatments and lubricants minimize this concern in professional installations.

Many of our global clients in the aftermarket performance, tuning, and motorsport industries specifically request titanium lug nuts for their high-end applications—not only because of their safety but also due to customer trust and brand perception.

Are Titanium Lug Nuts Stronger Than Steel?

Steel is strong, yes—but strength isn’t the only metric that matters when sourcing for performance.

Titanium vs Steel: What Buyers Need to Know

| Property | Titanium (Grade 5) | Steel (Grade 10.9 / 12.9) |

|---|---|---|

| Tensile Strength | ~950 MPa | ~1040–1200 MPa |

| Weight | ~45% lighter than steel | Heavier |

| Corrosion Resistance | Exceptional (no rust) | Requires coatings |

| Temperature Stability | Excellent | May lose strength under heat |

| Visual Appeal | Polished, anodizable | Basic or plated |

While steel might edge out titanium in raw tensile strength, Titanium’s strength-to-weight ratio is significantly higher. This makes it ideal for reducing unsprung mass—a huge factor in performance vehicle dynamics. For motorsport clients or high-end consumers, this translates to:

Faster acceleration

Better handling

Improved fuel efficiency

Longer-lasting wheel hardware

From a sourcing perspective:

Lighter products reduce international shipping costs per unit

Longer lifespan means better ROI for your end-users

Premium appeal increases margins in both wholesale and retail

When offering clients an upgrade from steel to titanium, it’s not just a materials change—it’s a complete step up in product class.

Why Polished Titanium Lug Nuts Are a Profitable Choice?

When buyers look for an edge—either in quality, aesthetics, or customer satisfaction—titanium lug nuts offer distinct advantages:

Visual Impact Sells

The polished finish elevates even stock wheels to show-car status. For shops, tuners, or distributors serving appearance-conscious customers, polished titanium lug nuts are an easy upsell.

Inventory Efficiency

Titanium’s corrosion resistance and universal appeal across JDM, Euro, and domestic performance markets make it a low-risk, high-return addition to any inventory.

Available in popular thread sizes: M12x1.25 / M12x1.5 / M14x1.5

Compatible with most aftermarket and OEM wheels

Easily anodized for custom colors—blue, gold, purple, rainbow, and more

Global Appeal

Whether you're distributing in the U.S., Germany, Japan, Australia, or the Middle East, polished titanium lug nuts meet the expectations of performance buyers across markets.

Who Is Buying These and Why You Should Stock Them

From our global client base, the most frequent bulk purchasers of Titanium Wheel Lug Nuts With Polished Finish include:

Motorsport distributors and teams

Performance parts retailers

Tuning shops offering wheel customization

Wheel and tire wholesalers

Exporters to high-humidity or salt-heavy regions

They consistently report higher customer satisfaction, reduced complaints, and increased average order value after adding titanium lug nuts to their product catalogs.

Cost vs Long-Term Value

Yes, titanium lug nuts carry a higher initial cost. But when considering:

Reduced maintenance and replacement

Lower corrosion-related returns

Higher resale value

Lower shipping weight

Stronger brand image for your company

…it becomes clear that the cost is an investment, not an expense.

In wholesale transactions, titanium lug nuts can help differentiate your product line and command better margins. When sold in bulk, unit prices become competitive—especially with a direct manufacturer.

Let’s Talk Business

If you're a purchasing manager, importer, or distributor looking to:

Expand your product portfolio with high-performance, high-demand fasteners

Reduce product quality risks

Impress high-end clients

Offer a corrosion-free solution with true global appeal

Then it’s time to talk about Titanium Wheel Lug Nuts With Polished Finish.

We are a direct manufacturer and global supplier specializing in titanium automotive fasteners. Our products meet international standards and are backed by strict quality inspections, test reports, and customized packaging.

Phone / WhatsApp: +8618392721678

Email: Jolina@bjhyti.com

Reach out now to request catalogs, MOQ pricing, shipping estimates, or to discuss OEM customization.

Whether you're sourcing for retail, racing, or private label, we are here to support your business growth with premium titanium solutions.

References

BONOSS. “Are Titanium Lug Nuts Worth It?”

Titanium Metals Corporation. “Ti-6Al-4V Alloy Properties and Applications.”

RacingLine Performance. “Motorsport Hardware Upgrades.”

Fastener Engineering. “Material Choices in Automotive Fasteners.”

Reddit r/cars. “Real User Reviews on Titanium Lug Nuts.”

GlobalAutoPerformance. “High-Temperature Resistant Fasteners.”

Motorsports Weekly. “Top Lightweight Components for Race Cars.”

Engineering Toolbox. “Mechanical Properties of Metals.”

Learn about our latest products and discounts through SMS or email

(1)(1)(1)_1736994898747.webp)