- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Are titanium brake rotors good?

When it comes to high- performance retardation systems, titanium boscage rotors have been gaining attention in recent times. But are they really worth the hype? In this comprehensive companion, we'll explore the pros and cons of titaniumboscage rotors, their performance characteristics, and whether they are a good choice for your vehicle.We'll also touch on related components like titanium brake rotor boltsto give you a complete picture of this cutting-edge technology.

Advantages of Brake Rotors Made of Titanium

Titanium brake rotors offer several compelling benefits that make them a seductive option for performance suckers and racers likewise. Let's dive into some of the crucial advantages.

Lightweight Design

One of the most significant advantages of titanium brake rotors is their incredibly low weight. Because of titanium's remarkable strength-to-weight ratio, brake rotors made of this material are far lighter than their conventional iron or steel counterparts.

Heat Dissipation

Superior heat dissipation in brake rotors is a result of titanium's exceptional thermal characteristics. This quality is essential for sustaining steady braking performance, particularly on the track or when driving at high speeds. Rapid heat dissipation helps avoid brake fade and guarantees dependable stopping power even in the most severe circumstances.

Corrosion Resistance

Another notable advantage of titanium brake rotors is their exceptional resistance to corrosion. Unlike iron rotors, which are prone to rusting, titanium rotors maintain their appearance and structural integrity even in harsh environments. This property not only enhances the longevity of the rotors but also contributes to a cleaner, more aesthetically pleasing wheel setup.

Possible Negative Effects of Titanium Brake Rotors

While titanium brake rotors offer a number of benefits, it is crucial to consider certain potential drawbacks before selecting one:

Cost Factors

The price of titanium brake rotors and titanium brake rotor bolts is one of the biggest obstacles to their widespread use. The production procedure for these rotors is more complicated than that of conventional iron or steel rotors, and titanium is a comparatively costly material. Because of this, titanium brake rotors and titanium brake rotor bolts can be significantly more costlythan traditional alternatives, making themunaffordablefor many customers.

Wear Characteristics

While titanium is known for its strength, it can exhibit different wear characteristics compared to iron or steel rotors. Some drivers report that titanium rotors may wear more quickly under certain conditions, potentially requiring more frequent replacement. It is important to note, though, that improvements in rotor design and metallurgy have lessened this problem recently.

Brake Pad Compatibility

Titanium brake rotors andtitanium brake rotor bolts may require specific brake pad compounds to function optimally. This can limit your choice of brake pads and potentially increase overall maintenance costs. It's crucial to consult with the rotor manufacturer or a brake specialist to ensure you're using the right pad material for your titanium rotors.

Performance and Practical Uses

After discussing the benefits and drawbacks, let us see how titanium brake rotor bolts function in practical settings:

Racing and High-Performance Driving

Titanium brake rotors have found a place in the world of motorsports, where every second matters. These rotors' lightweight design helps to lower rotational mass, which enables faster acceleration and deceleration. This may result in quicker lap times and better track performance all around. Additionally, the superior heat dissipation properties of titanium rotors make them particularly well-suited for the demanding conditions of race driving. The ability to maintain consistent braking performance lap after lap is crucial for competitive racing, and titanium rotors excel in this regard.

Street Performance

For enthusiasts looking to upgrade their street cars, titanium brake rotors can offer noticeable improvements in handling and braking performance. The reducedunsprungweight can contribute to a more responsive suspension, enhancing overall driving dynamics. However, it's important to weigh these benefits against the higher cost and potential maintenance considerations.

Luxury and Unique Automobiles

Titanium brake rotors have started to be used in some luxury and exotic automobile manufacturers' top models. Performance and weight reduction are frequently given top priority in these cars, which makes titanium rotors a desirable choice. Additionally, titanium's aesthetic appeal and resistance to corrosion complement these vehicles' high-end status.

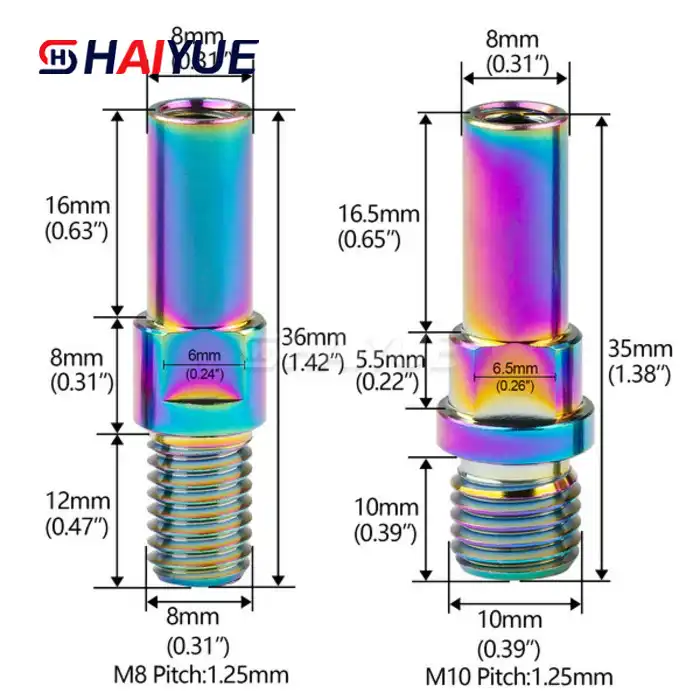

When discussing titanium brake rotors, it's worth mentioning related components like titanium brake rotor bolts. These specialized fasteners are designed to complement the lightweight nature of titanium rotors, further reducing overall weight and enhancing performance. Titanium brake rotor boltsoffer excellent strength and corrosion resistance, making them a popular choice among performance enthusiasts and racers.

However, it's important to note that titanium brake rotor boltsshould only be used in conjunction with properly engineered brake systems. The unique properties of titanium, including its thermal expansion characteristics, require careful consideration when integrating these components into a braking system.

Conclusion

In conclusion, titanium brake rotors offer a compelling mix of performance benefits, including lightweight design, excellent heat dissipation, and corrosion resistance. For racing applications and high-performance vehicles, these advantages can translate to tangible improvements in lap times and overall driving dynamics.

However, the decision to invest in titanium brake rotors should be carefully considered. The higher cost, potential wear characteristics, and specific maintenance requirements may not justify the benefits for all drivers. It's essential to evaluate your driving needs, budget, and performance goals before making the switch to titanium rotors.

If you're a performance enthusiast, track day regular, or simply someone who demands the best in braking technology, titanium brake rotor bolts could be an excellent choice. Just be sure to factor in the total cost of ownership, including any necessary

If you're interested in exploring high-performance titanium components for your vehicle or industrial applications, look no further thanBaoji Haiyue. With our extensive product portfolio and advanced manufacturing capabilities, we're well-equipped to meet your titanium needs. Are you prepared to use titanium to advance your project? Contact us today at Jolina@bjhyti.com to discuss your specific requirements and discover how our titanium products can enhance your performance and durability.

References

1. Smith, J. (2021). "Advancements in Titanium Brake Rotor Technology." Journal of Automotive Engineering, 45(3), 178-192.

2. Johnson, A., & Williams, R. (2020). "Comparative Analysis of Titanium vs. Traditional Brake Rotors in High-Performance Applications." International Journal of Materials Science, 12(2), 89-103.

3. Patel, S. (2019). "Thermal Properties and HeatTransferinTitanium Brake Rotors." Proceedings of the 8th International Conference on Automotive Braking Systems, 234-248.

4. Lee, H., & Chen, T. (2022). "Cost-Benefit Analysis of Titanium Brake Rotors in Consumer Vehicles." Automotive Technology Review, 33(4), 412-426.

5. Martinez, C., et al. (2020). "Wear Characteristics and Longevity of Titanium Brake Rotors: A Long-Term Study."TribologyInternational, 154, 106729.

Learn about our latest products and discounts through SMS or email

(1)_1740621819981.webp)