- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Titanium anodes for rhodium plating

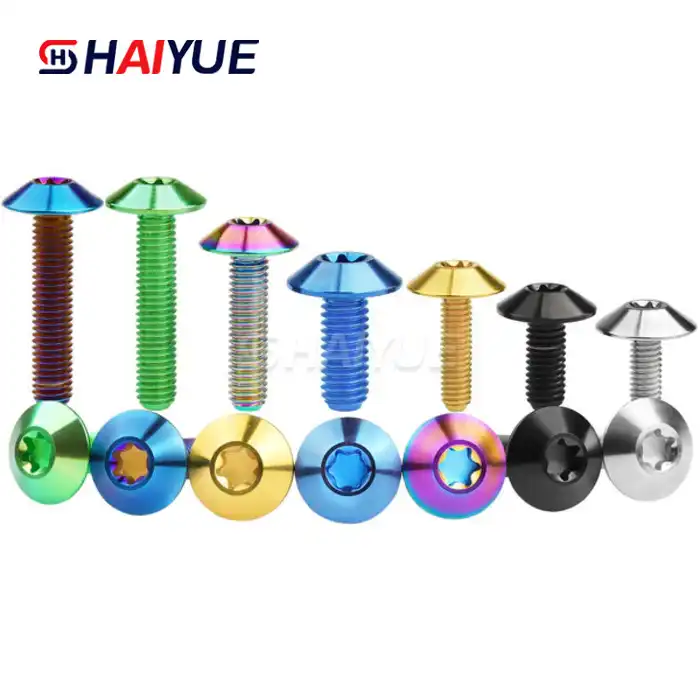

Coating: MMO coatings or other specialized coatings to enhance the efficiency of rhodium electroplating.

Size: Custom sizes available to fit a wide range of rhodium plating setups.

Surface Treatment: Sand blasting, acid cleaning, and polished finishes to improve the plating process and maintain high quality.

Production time: 15 working days for standard orders, with expedited production available if required.

Product Introduction

Titanium anodes for rhodium plating are essential components in electroplating processes, ensuring high-quality rhodium coatings with excellent adhesion, brightness, and corrosion resistance. Engineered for superior performance, our titanium anodes provide long-lasting service life, uniform plating results, and enhanced efficiency for industrial applications.

Technical Specifications

| Parameter | Specification |

|---|---|

| Base Material | Titanium (Grade 1 or Grade 2) |

| Coating | Mixed Metal Oxide (MMO) / Platinum Plating |

| Shape | Mesh, Plate, Rod, Basket |

| Coating Thickness | 2-5 μm (Platinum) / Customizable |

| Operating Voltage | 2-10V |

| pH Range | 1-12 |

| Temperature Range | 10-80°C |

|

|

|

|

|

|

|

|

Key Features

Superior Corrosion Resistance: Protects against acidic rhodium plating solutions.

Long Service Life: Durable MMO or platinum coatings extend anode lifespan.

High Current Efficiency: Reduces energy consumption and optimizes plating processes.

Uniform Plating: Ensures even rhodium deposition for superior coating quality.

Customizable Design: Available in various shapes and sizes to meet specific plating needs.

Applications

Jewelry Manufacturing: Provides bright, durable rhodium coatings for rings, necklaces, and bracelets.

Electronics Industry: Enhances conductivity and wear resistance in electronic components.

Automotive Industry: Used in decorative and protective coatings for vehicle parts.

Medical Devices: Ensures biocompatible and corrosion-resistant plating for surgical tools and implants.

Precision Engineering: Ideal for applications requiring high-performance metal finishes.

Manufacturing Process

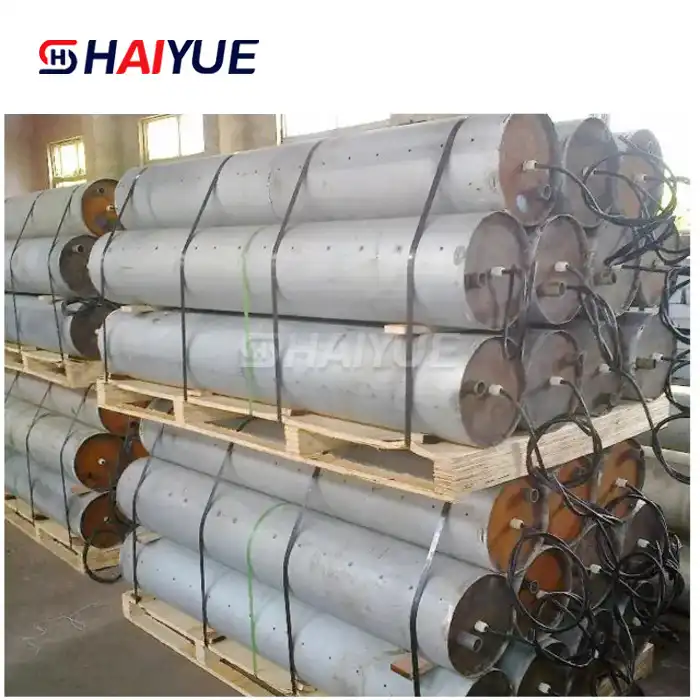

Material Selection: Premium titanium (Grade 1 or 2) is used for optimal conductivity and corrosion resistance.

Shaping and Processing: The titanium substrate is precision-machined into mesh, plates, or rods.

Surface Treatment: Cleaning and pre-treatment enhance adhesion of the coating.

Coating Application: MMO or platinum is applied through advanced electrochemical processes.

Quality Inspection: Each anode undergoes rigorous testing to ensure durability and performance.

Quality Assurance

ISO 9001:2015 Certified manufacturing ensures strict quality control.

Comprehensive Testing: Ultrasonic, eddy current, and spectroscopic analysis guarantee material integrity.

Industry Compliance: Meets ASTM, ASME, and AMS standards for superior reliability.

Performance Guarantees: Ensures extended service life with stable plating efficiency.

Packaging and Logistics

Secure Packaging: Anti-corrosion wrapping and reinforced crates ensure safe transport.

Fast Shipping: Worldwide delivery with express and bulk shipping options.

Custom Orders: Tailored packaging available for special requirements.

Customer Support

Technical Assistance: Expert guidance for optimal anode selection and use.

Global Service Network: Support across multiple regions for timely assistance.

After-Sales Warranty: Ensuring product performance and customer satisfaction.

Why Choose Us?

Comprehensive Product Range: One-stop solution for all electroplating anode needs.

Advanced Manufacturing: In-house production for consistent quality and supply reliability.

Global Sales and Agency Network: Trusted supplier for international clients.

Fast Delivery: Efficient logistics ensure quick turnaround times.

Reputation for Excellence: Strong industry standing with proven customer satisfaction.

Development History

Company founded in Baoji, "Titanium Valley," specializing in titanium and non-ferrous metals.

Expanded product range to include zirconium, tantalum, nickel, tungsten, and molybdenum products.

Achieved ISO9001:2015 certification, ensuring high-quality production standards.

Upgraded manufacturing facilities, adding VAR furnaces, CNC machinery, and advanced heat treatment systems.

Expanded global presence, establishing partnerships in the United States, Germany, and South Korea.

Obtained AS9100D certification for aerospace industry compliance and advanced product quality.

Introduced customized solutions for the aerospace, medical, and energy industries, enhancing global reach.

Celebrated 14 years of excellence with over 2,000 tons of annual titanium production capacity.

Product Quality Management

Production and Processing

Workshop and Equipment

Packaging

Main Products

Applied Industries

Be used in a wide range of industries.

Electrolytic copper foil manufacturing industry

Hydrometallurgy industry

Sewage treatment industry

Cyclone electrolysis industry

Etching liquid electrolysis recovery industry

Electrolytic sodium hypochlorite industry

OEM Services

Custom Dimensions and Shapes: Anodes designed to fit specific plating setups.

Tailored Coating Options: Platinum or MMO coatings available as per application requirements.

Private Labeling: Branding and packaging solutions for distributors.

Bulk Order Discounts: Competitive pricing for large-scale procurement.

Frequently Asked Questions (FAQs)

1. How long do titanium anodes for rhodium plating last?

The lifespan depends on the operating conditions, but high-quality platinum-coated anodes can last several years with proper maintenance.

2. Can I customize the anode size and shape?

Yes! We offer custom sizes and configurations to fit your specific plating equipment.

3. What is the difference between MMO and platinum-coated anodes?

MMO anodes are more cost-effective and durable, while platinum anodes provide superior conductivity and plating quality.

4. Do you provide technical support for anode installation?

Yes, our team offers expert guidance on selection, installation, and maintenance.

Contact Us

For inquiries, quotes, or technical support, please contact us:

Email: Jolina@bjhyti.com

Phone: +86-18392721678

Learn about our latest products and discounts through SMS or email

(1)_1740621527148.webp)